Dust removal equipment with collecting and screening functions for metal powder production

A technology of metal powder and dust removal equipment, which is applied in the field of dust removal equipment, can solve problems such as single function, waste of resources, and failure to sieve and collect, and achieve the effects of avoiding flying, convenient recycling, and difficult collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

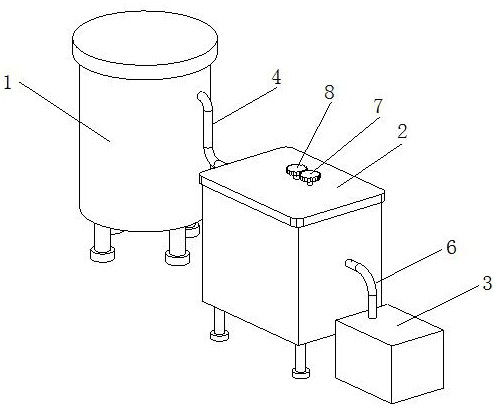

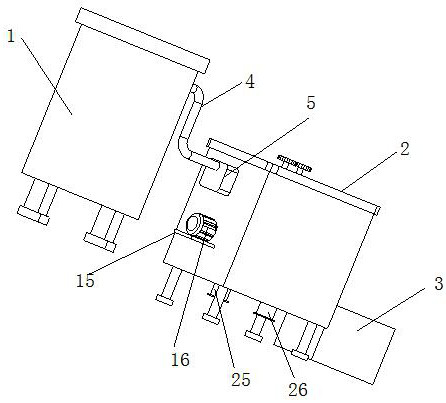

[0028] see Figure 1-Figure 5 , the present invention provides a technical solution: a dust removal equipment for metal powder production with the function of collecting and screening, comprising a metal powder processing box 1, a dust removal and screening box 2 is arranged on one side of the metal powder processing box 1, and a dust removal and screening box The side of the box 2 away from the metal powder processing box 1 is provided with a purification box 3, and the outer wall of one side of the metal powder processing box 1 is fixedly connected with the first connecting pipe 4, and the dust removal and screening box 2 and the purification box 3 pass through the second connecting pipe 6 Connected, the inner wall of the purification box 3 is fixedly equipped with a vacuum cleaner, the outer wall of one side of the dust removal and screening box 2 is fixedly connected with a fan 5, and the end of the first connecting pipe 5 away from the metal powder processing box 1 is fixe...

Embodiment 2

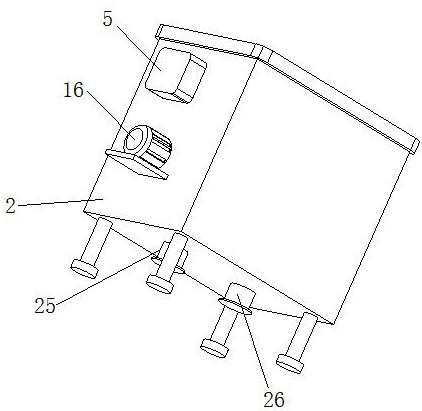

[0031] see Figure 1-Figure 6On the basis of Embodiment 1, the present invention provides a technical solution: the outer wall of one side of the dust removal and screening box 2 is fixedly connected with a mounting plate 15 under the fan 5, and the top outer wall of the mounting plate 15 is fixedly connected with a second motor. 16. The output shaft of the motor two 16 is fixedly connected with the second rotating shaft 17, and the end of the second rotating shaft 17 away from the output shaft of the motor two 16 is fixedly connected with an electromagnetic induction device 18, and the end of the electromagnetic induction device 18 far away from the second rotating shaft 17 is connected with the dust removal screen The inner wall of one side of the sub-box 2 is rotationally connected, the outer wall of one side of the dust removal and screening box 2 is fixedly connected with a power supply, the terminal of the power supply is electrically connected with the terminal of the el...

Embodiment 3

[0034] see Figure 7-Figure 8 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the outer walls on both sides of the filter screen 20 are fixedly connected with sliding plates 21, and the inner walls on both sides of the dust removal and screening box 2 are provided with sliding plates. Groove 22, the outer wall of sliding plate 21 is slidably connected with the inner wall of sliding groove 22, and the upper and lower inner walls of sliding groove 22 are fixedly connected with spring 23, and one end of spring 23 is fixedly connected with the outer wall of sliding plate 21, and the dust removal and screening box 2 Both sides of the inner wall of the inner wall are fixedly connected with drain plates 24, and the drain plates 24 are arranged diagonally and symmetrically.

[0035] In this embodiment, the motor 3 27 is started to move the filter screen 20 up and down. On the one hand, the dust is filtered, and on the other hand, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com