Whole substrate glass multi-piece crushing device and multi-piece crushing method

A crushing device and glass technology, applied in the direction of grain processing, etc., can solve problems such as low efficiency, and achieve the effects of high work efficiency, stable glass transportation, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

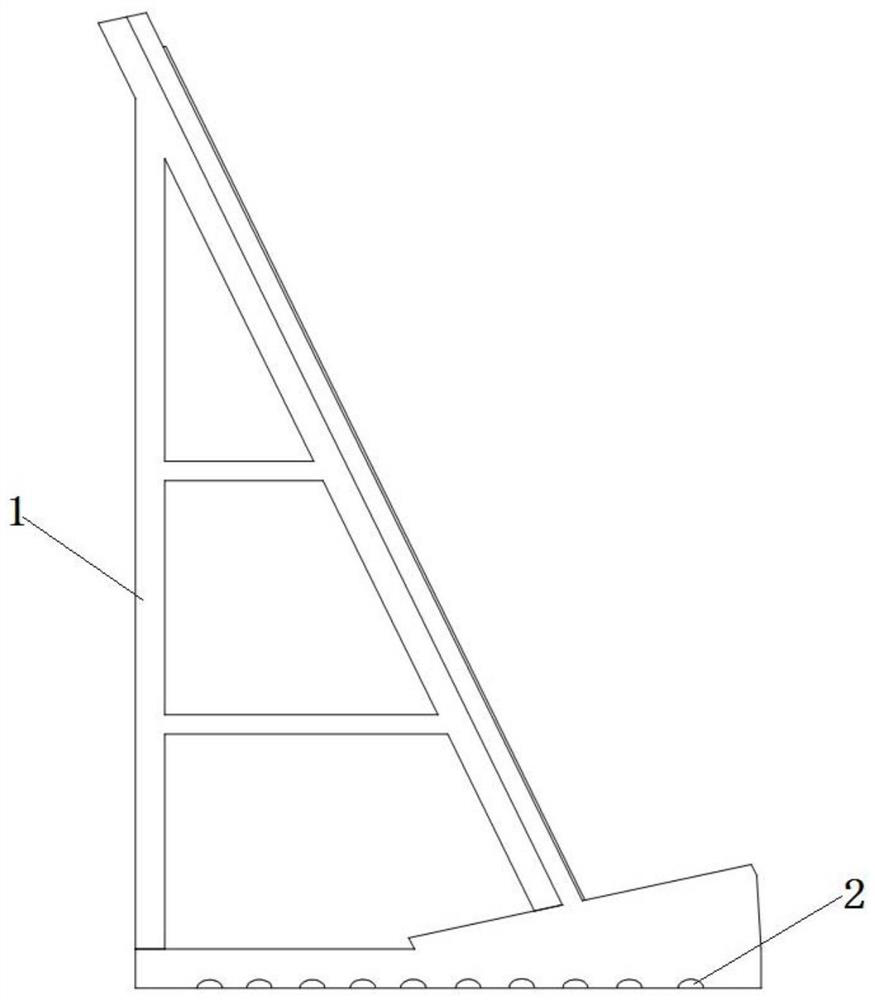

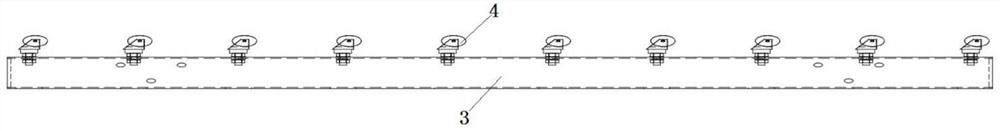

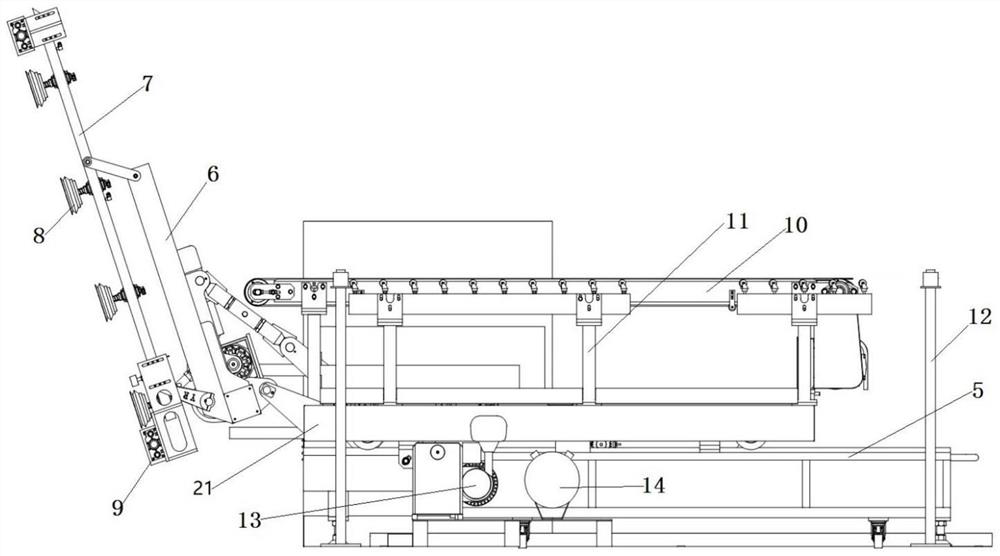

[0044]The present invention provides a multi-piece crushing device for the whole plate of substrate glass, which includes a transfer frame 1, a vacuum adsorption device, a plate chain conveyor belt 19 and a crushing device. Control the position of the glass 20 at the same time as the Z direction, and indirectly position the glass 20 on the transfer rack 1. In this embodiment, the transfer rack 1 adopts an A-type transfer rack, and one of the inclined surfaces of the A-type transfer rack It is used to place the substrate glass. The offset between the center line of the substrate glass and the center line of the transfer frame 1 cannot exceed 20mm, so as to ensure that when the vacuum adsorption device absorbs the substrate glass, all the suction cups 8 on the vacuum adsorption device can be adsorbed on the substrate glass. , to ensure the transp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com