Surface polishing device for stainless steel product production

A surface polishing and stainless steel technology, which is applied in the direction of surface polishing machine tools, grinding drive devices, grinding/polishing equipment, etc., can solve the problems of shaking stainless steel products, inconvenient polishing of stainless steel products, and low polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

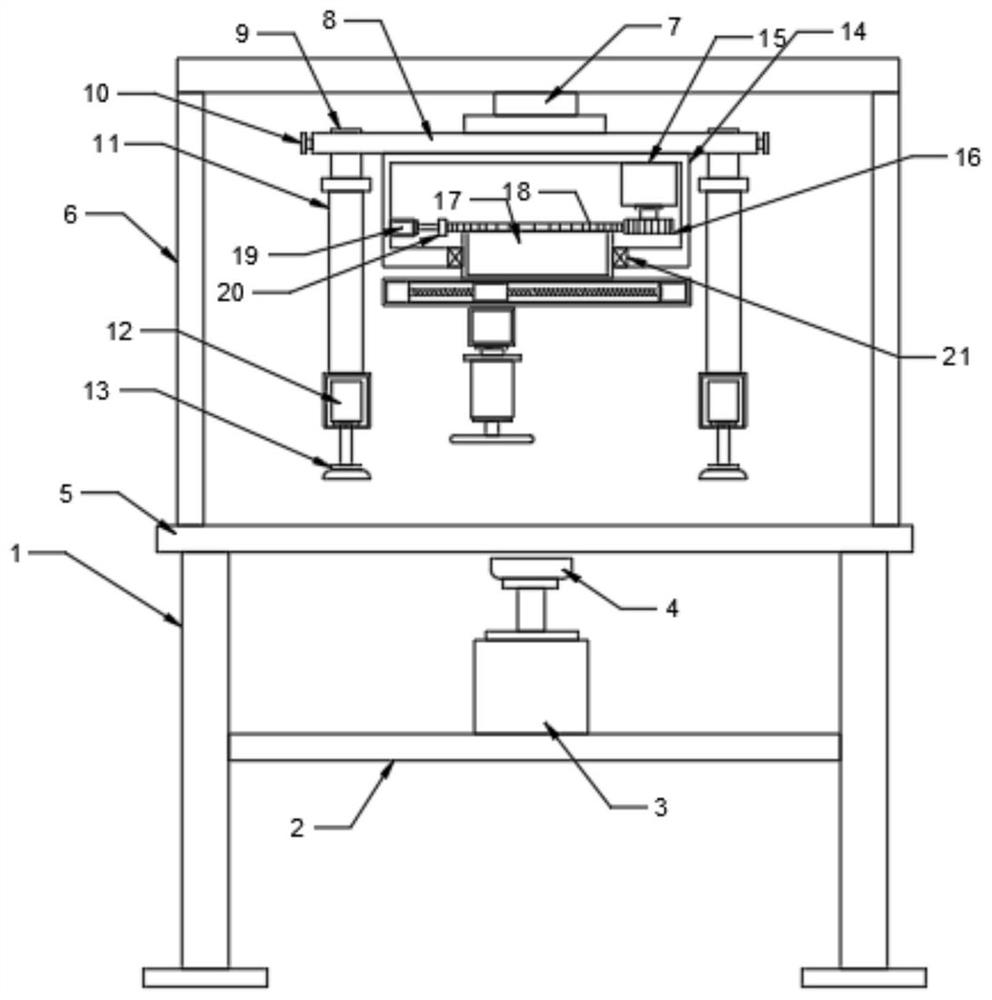

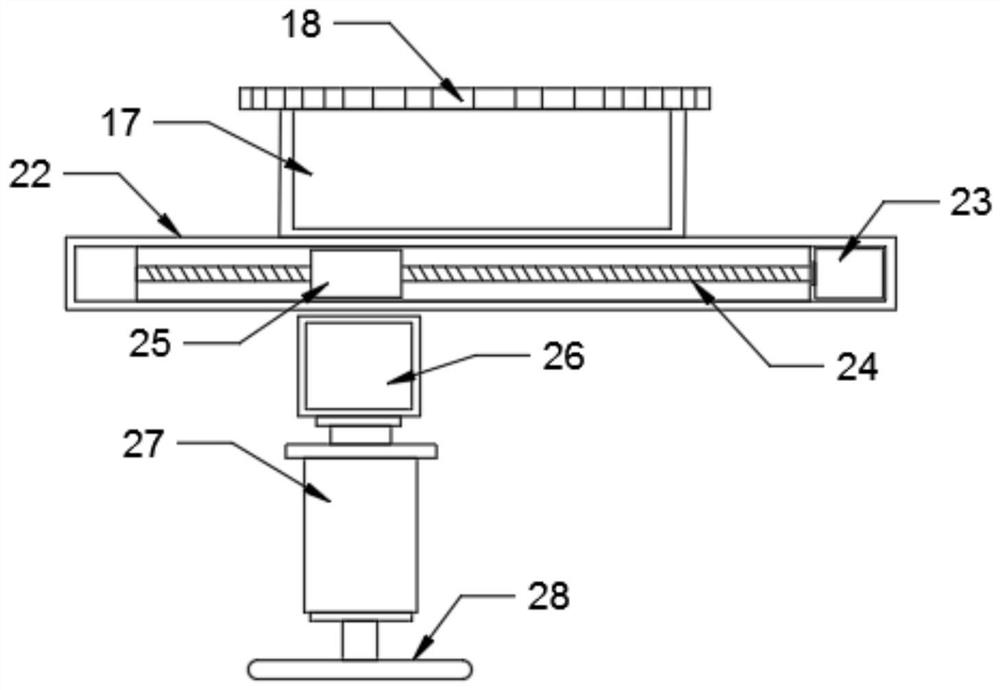

[0024] see Figure 1~4 , in an embodiment of the present invention, a surface polishing device for producing stainless steel products, including a support base 1, a rotating shaft 7 and a polishing disc 28, a fixed plate 2 is installed on the inner side of the support base 1, and a second fixed plate is installed in the middle of the upper end of the fixed plate 2. A telescopic motor 3, the front end of the first telescopic motor 3 is equipped with a first sucker 4; the upper end of the support seat 1 is equipped with a support plate 5, a through hole in the middle of the support plate 5, and the diameter of the through hole is the same as the diameter of the first suction cup 4; the support plate 5 A fixed frame 6 is installed on the upper end.

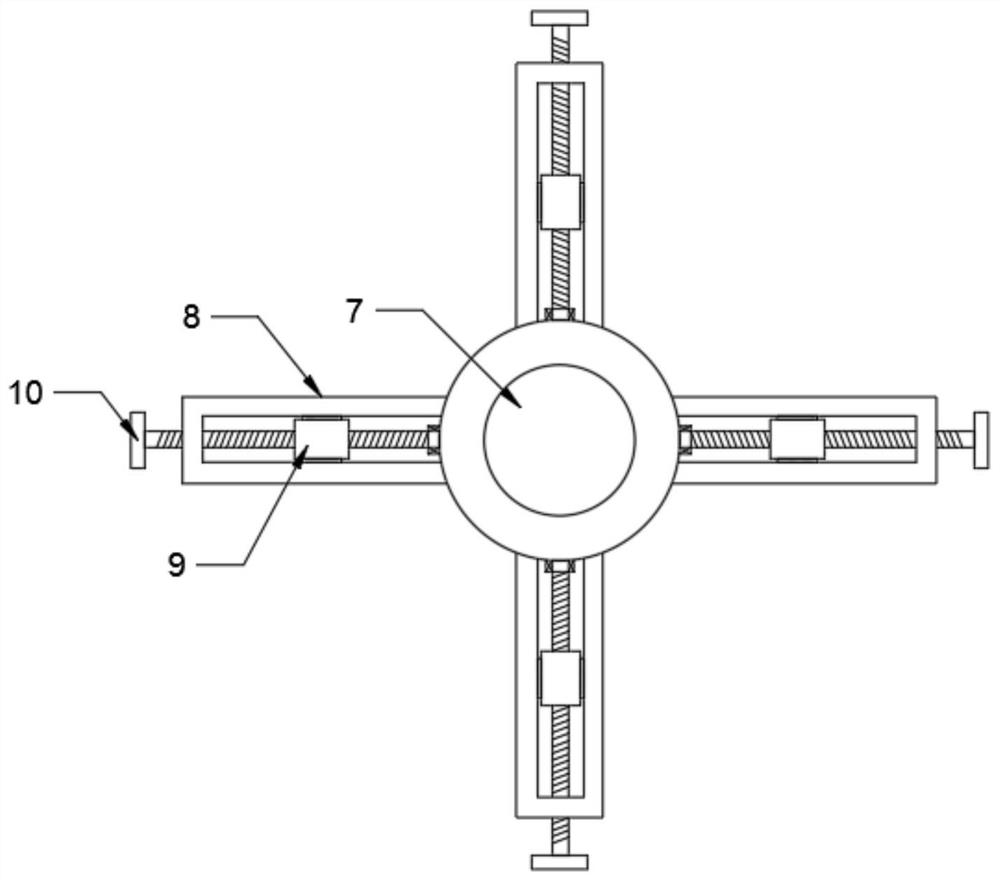

[0025] The middle part of the inside top of the fixed mount 6 is equipped with a rotating shaft 7, and the limit frame 8 is installed outside the bottom end of the rotating shaft 7, and the inside of the limit frame 8 is equipped wit...

Embodiment 2

[0029] see Figure 5 , in an embodiment of the present invention, a surface polishing device for producing stainless steel products includes a support base 1, a rotating shaft 7 and a polishing disc 28, a support plate 5 is installed on the upper end of the support base 1, and a fixing frame is installed on the upper end of the support plate 5 6. A rotating shaft 7 is installed in the top middle of the inner side of the fixed frame 6, and a limiting frame 8 is installed outside the bottom of the rotating shaft 7. A slider 9 is installed on the inner side of the limiting frame 8, and a first threaded rod 10 is installed in the middle of the slider 9. Block 9 bottom ends are equipped with long bar 11, and long bar 11 bottom ends are equipped with second telescopic motor 12, and the second telescopic motor 12 front end is equipped with second suction cup 13; Effectively improve the stability of stainless steel products, facilitate the fixing of stainless steel products, and facil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com