Polaroid pasting production line for pasting polaroid on glass workpiece

A polarizer, production line technology, applied in the direction of sending objects, furnace components, conveyor objects, etc., can solve the problems of complex production line structure, poor equipment cooperation performance, adhesion and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

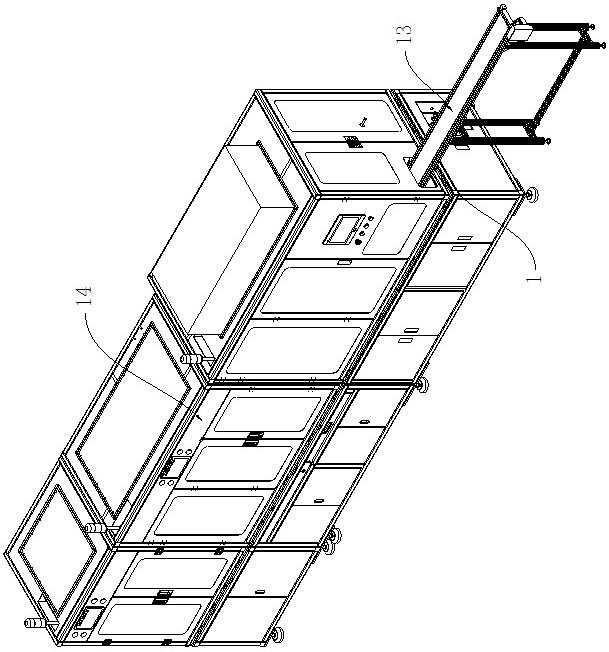

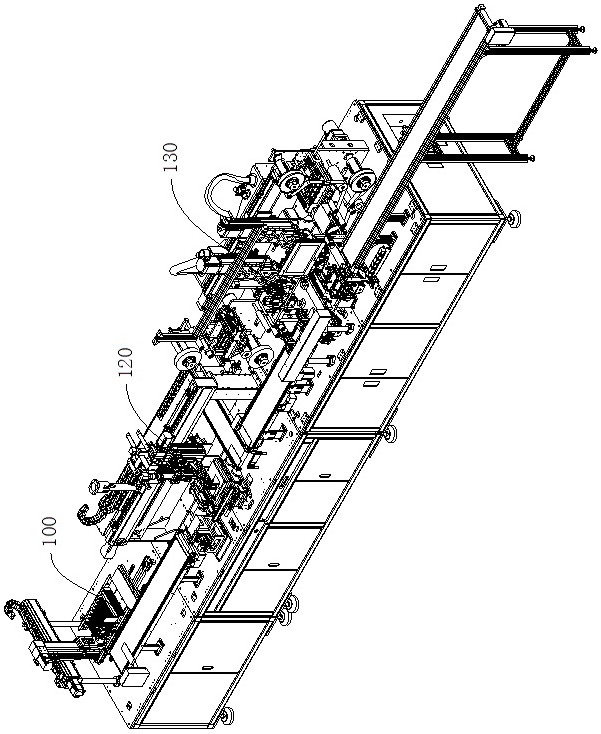

[0024] This embodiment proposes a patch production line for sticking polarizers on glass workpieces, combining Figure 1 to Figure 5 As shown, it includes a frame 1, the frame 1 is fixed with a box body 14, and a feeding mechanism 100, a material distribution mechanism 120 and a patch device 130 are arranged in the box body 14, wherein:

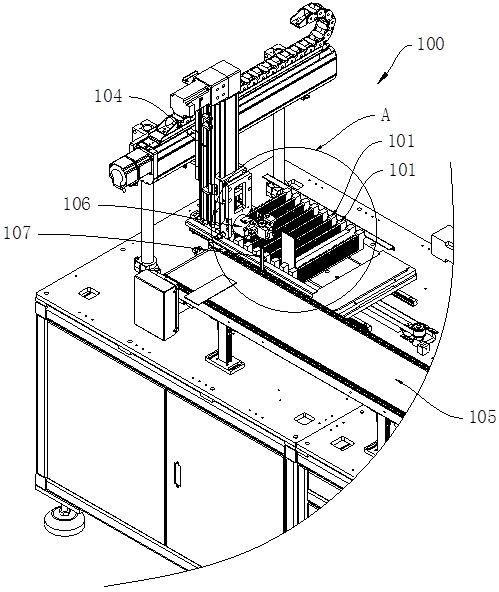

[0025] The feeding mechanism 100 includes a plurality of board racks 101 parallel to each other, a feeding robot arm 104 and a feeding conveyor belt 105, and a plurality of fins 102 are respectively formed on both sides of the board rack 101, An insertion opening 103 is formed between two adjacent fins 102, and the glass workpiece is vertically inserted into the insertion openings 103 on two adjacent insertion frames 101, and the driving end of the loading mechanical arm 104 is set Rotating arm 106 is arranged, and the rotating shaft of described rotating arm 106 is fixed with feeding strut 107, and the side of described feeding strut 107 is ...

Embodiment 2

[0031] This embodiment relates to a patching device for sticking polarizers on glass workpieces, combining Figure 1 to Figure 7 As shown, the placement equipment 130 includes a frame 1, and the frame 1 is provided with a feeding and conveying mechanism 2, a polarizer feeding mechanism 3, a pick-and-place mechanism 4, and a left patch platform mechanism 5. A left cleaning mechanism 6, a left sticker mechanism 7, a turning platform mechanism 8, a right patch platform mechanism 9, a right cleaning mechanism 10, a right sticker mechanism 11, a feeding manipulator 12 and a discharging Conveying mechanism 13, wherein:

[0032] The feeding and conveying mechanism 2 is used to receive the glass workpieces delivered by the distributing manipulator 121 and transport the glass workpieces;

[0033] The polarizer feeding mechanism 3 is arranged adjacent to the feeding conveying mechanism 2, and the polarizer feeding mechanism 3 is used to feed the polarizer to the left sticker mechanism ...

Embodiment 3

[0049] This embodiment proposes a polarizer double-chip detection and delivery mechanism that can improve the efficiency of polarizer feeding and delivery, and can ensure single-chip delivery. Figure 6 and Figure 8 As shown, it includes a polarizer feeding mechanism 3, and the polarizer feeding mechanism 3 includes a material box 30, a tape conveying device 31, a tape recycling device 35 and an optical fiber through-beam sensor 33, and the tape conveying device 31 and the The adhesive tape 32 is used to transport the adhesive tape 32 between the adhesive tape recycling devices 35, and the adhesive tape 32 is conveyed through the head sticking mechanism of the patch equipment, and the multi-layer polarizer is placed in the magazine 30, and the adhesive tape 32 is located The bottom of the material box 30, and the adhesive tape 32 is in contact with the polarizer, the polarizer is pasted by the adhesive tape 32 and the polarizer is transferred to the bottom of the head stickin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com