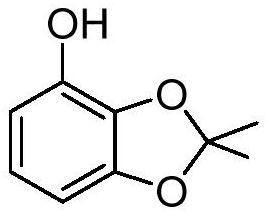

The synthetic method of 4-hydroxy-2,2-dimethyl-1,3-benzodioxol

A synthesis method and dimethyl technology, applied in organic chemistry and other directions, can solve the problem of difficult selection of resin catalysts, and achieve the effects of reducing the solvent feeding ratio, reducing the generation probability of impurities, and simplifying the operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

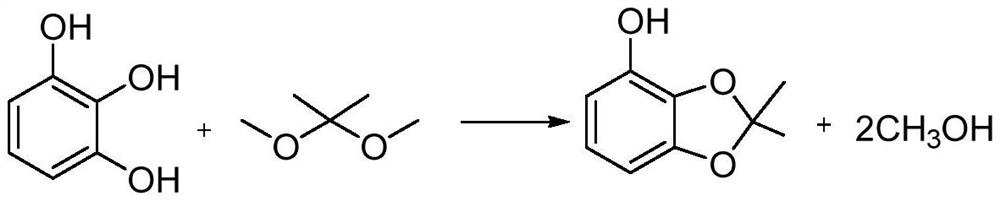

[0029] A kind of synthetic method of 4-hydroxyl-2,2-dimethyl-1,3-benzodioxol of the present invention comprises the following steps:

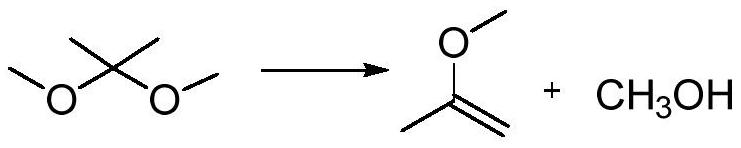

[0030] On a 1000mL stirred reactor A gas phase separation device with a height of 600mm and a condenser (such as a gas phase separation tower), the jacket of the gas phase separation device is fed with hot water. Add pyrogallic acid (99%, 0.8mol) 101.8g, toluene 509g in the reaction kettle, stir to dissolve, be warmed up to 110 ℃, begin to dropwise add 2-methoxypropene (98%, 0.96mol) 70.5g, while During the dropwise addition, the addition was completed in 6 hours by controlling the rate of addition of 2-methoxypropene. The by-product methanol and the toluene entrained by the reflux (may also contain a small amount of 2-methoxypropene) are separated through the gas phase separation device, the methanol is collected by the condenser, and the toluene is separated back to the reactor. After the reaction was completed, precipitation under reduced...

Embodiment 2

[0032] A kind of synthetic method of 4-hydroxyl-2,2-dimethyl-1,3-benzodioxol of the present invention comprises the following steps:

[0033] On a 1000mL stirred reactor A gas phase separation device with a height of 600mm and a condenser, the jacket of the gas phase separation device is fed with hot water. Add 101.8 g of pyrogallic acid (99%, 0.8 mol) and 610.8 g of toluene to the reaction kettle, stir and dissolve, heat up to 110° C., start to drop 2-methoxypropene (98%, 0.96 mol) 70.5 g, React while adding dropwise, control the drop rate of 2-methoxypropene, and finish adding in 8 hours. The by-product methanol and the toluene entrained by the reflux are separated through the gas phase separation device, the methanol is collected through the condenser, and the toluene is separated back to the reactor. After the reaction was completed, precipitation under reduced pressure, crystallization at low temperature, filtration, and vacuum drying gave 119.3 g of 4-hydroxy-2,2-dime...

Embodiment 3

[0035] A kind of synthetic method of 4-hydroxyl-2,2-dimethyl-1,3-benzodioxol of the present invention comprises the following steps:

[0036] On a 1000mL stirred reactor A gas phase separation device with a height of 600 mm and a condenser, the jacket of the gas phase separation device is passed into hot water, and 101.8 g of pyrogallic acid (99%, 0.8 mol) and 610.8 g of toluene are added to the reaction kettle, stirred and dissolved, and the temperature is raised to 110 At ℃, start to add 94.0 g of 2-methoxypropene (98%, 1.28mol) dropwise, react while adding dropwise, control the rate of addition of 2-methoxypropene, and complete the addition within 10 hours. The by-product methanol and the toluene entrained by the reflux are separated through the gas phase separation device, the methanol is collected through the condenser, and the toluene is separated back to the reactor. After the reaction was completed, precipitation under reduced pressure, crystallization at low tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com