Water gas production system, production process and control method

A technology of production system and control method, which is applied in the direction of gasification process, separation method, chemical instrument and method, etc., to achieve the effects of small steam consumption, high steam decomposition rate, and reduced emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Since the production system in the prior art still adopts the traditional method of reacting water vapor and high-temperature carbon layer to prepare water gas, not only the steam decomposition rate is low, but the steam consumption is large, and it is easy to pollute the environment. In order to solve this problem, this embodiment proposes a water gas production system. During the operation of the water gas production system, water and alcohol are used as raw material liquids to prepare water gas; specifically:

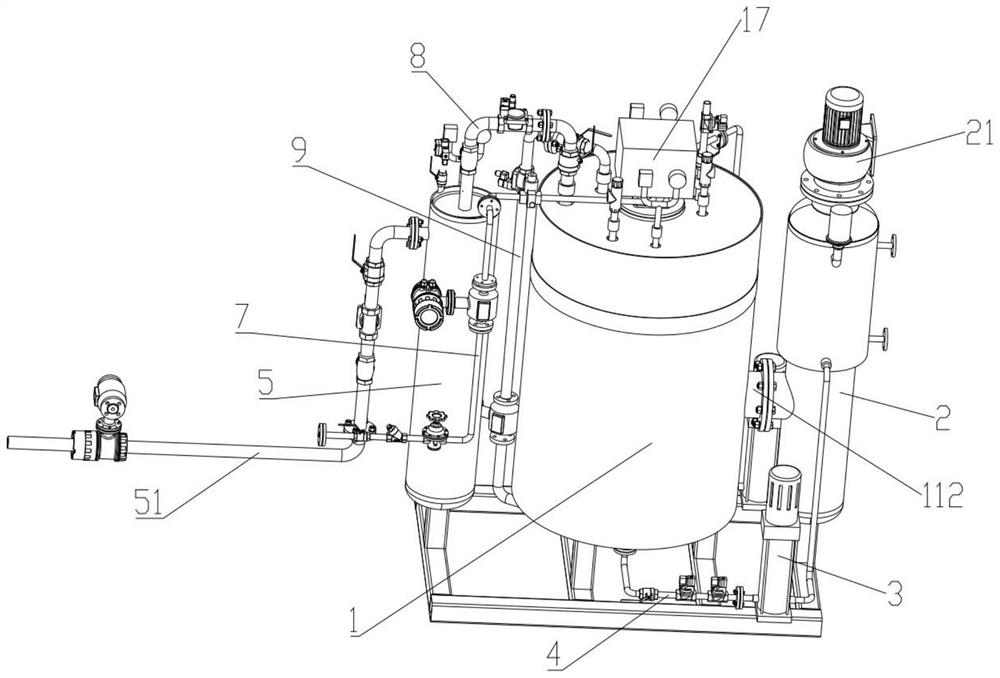

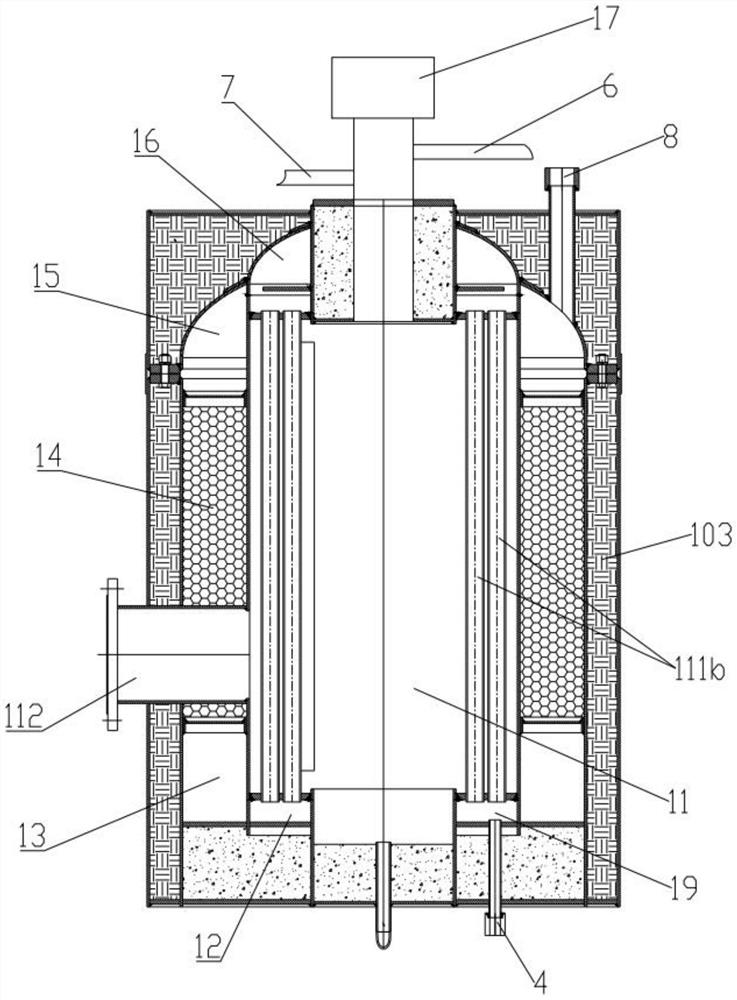

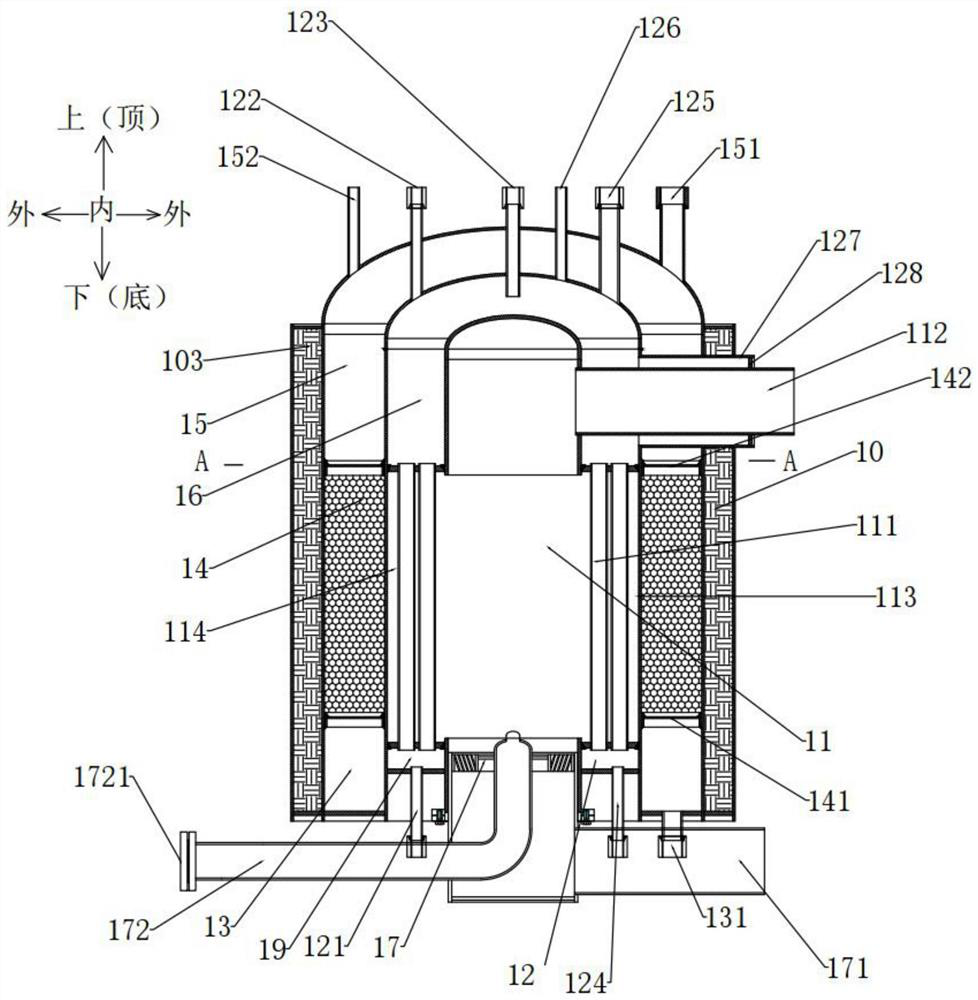

[0067] as attached Figure 1-4 As shown, the production system includes an integrated burner 1, a fan, a liquid storage tank 2, a gas collection device 5, and a fuel supply device. The integrated burner 1 includes at least a combustion chamber 11, a raw material liquid chamber 12, a water gas Preparation room, in the present invention, during the normal operation of the production system, at least the combustion process of fuel and the preparation process of w...

Embodiment approach 2

[0083] For the second embodiment, the raw material liquid chamber 12 may be arranged above the water gas preparation chamber, or may be arranged below the water gas preparation chamber.

Embodiment 2

[0085] Because the catalytic reaction that occurs in the water gas preparation chamber often needs to reach a certain temperature condition, so the application transfers a part of the heat to the water gas preparation chamber by utilizing the combustion process in the combustion chamber 11, so that the water gas preparation chamber can maintain the required temperature. reaction temperature conditions.

[0086] Therefore, in order to maintain the production and preparation process of water gas, the combustion process needs to be maintained in the combustion chamber 11, such as the attached Figure 1-3 As shown, the present embodiment improves the production system on the basis of Embodiment 1:

[0087] The production system includes a fuel supply device and a fuel pipeline 7, the inlet end of the fuel pipeline 7 is connected to the fuel supply device, and the outlet end of the fuel pipeline 7 is connected to the burner 17, so that the integrated burner 1. The internal tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com