A parallel test device and method for testing the reliability of hydraulic pumps and hydraulic reversing valves

A technology of hydraulic reversing valve and test device, which is applied in the direction of fluid pressure actuation device, fluid pressure actuation system test, fluid pressure actuation system components, etc. It can solve the problems of long time consumption, few specifications and types, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with embodiment the present invention is described in further detail:

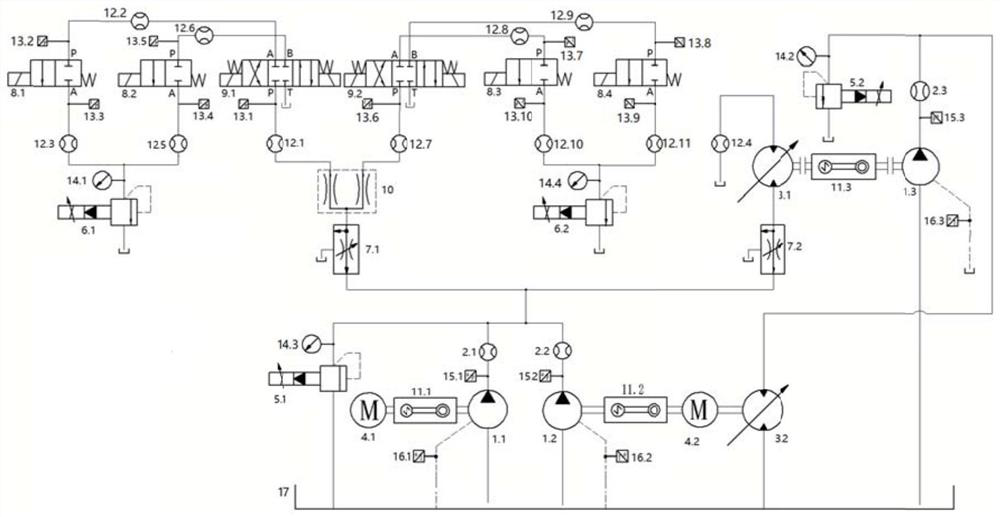

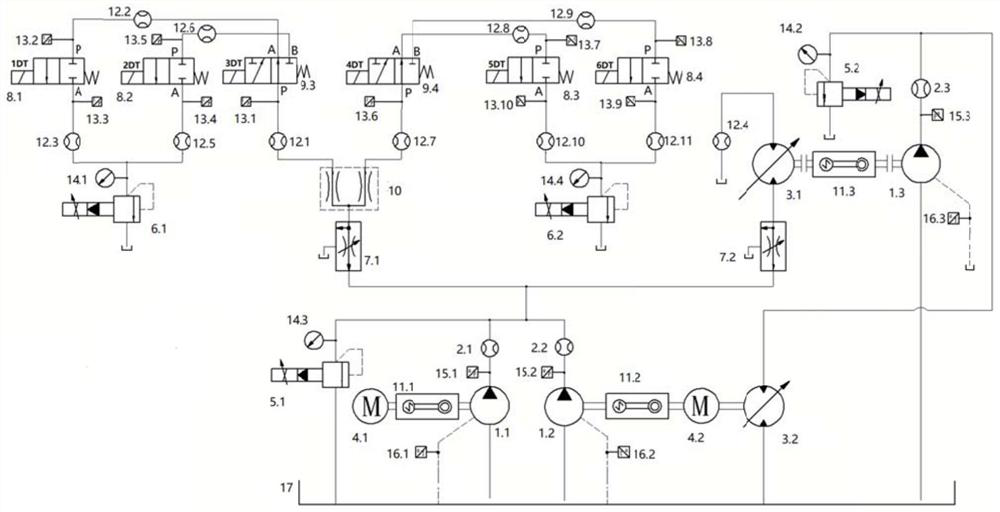

[0044]A parallel test device for testing the reliability of hydraulic pumps and hydraulic reversing valves, including a pump test module and a valve test module, in the pump test module, there are three hydraulic pumps to be tested, which are respectively the first hydraulic pump to be tested 1.1, The second tested hydraulic pump 1.2 and the third tested hydraulic pump 1.3, the first tested hydraulic pump 1.1, the second tested hydraulic pump 1.2, and the third tested hydraulic pump 1.3 are respectively driven by a single-axis frequency conversion motor 4.1, a double Driven by the shaft extension frequency conversion motor 4.2 and the first variable frequency motor 3.1 to output pressure oil, the first torque tachometer 11.1 is installed between the first measured hydraulic pump 1.1 and the single shaft frequency conversion motor 4.1, and the second measured hydraulic pump A sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com