Low-energy-consumption pressure-controllable hydrogen production and supply device and fuel cell system

A fuel cell and controllable technology, applied in the direction of fuel cells, fuel cell additives, reactant parameter control, etc., can solve the problem that the hydrogen pressure cannot meet the working requirements of the fuel cell, increase the production cost and complexity of the system, and cannot realize the production Hydrogen-Hydrogen consumption rate and other issues to achieve the effect of reducing production cost and complexity, reducing potential risks, and smoothing output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

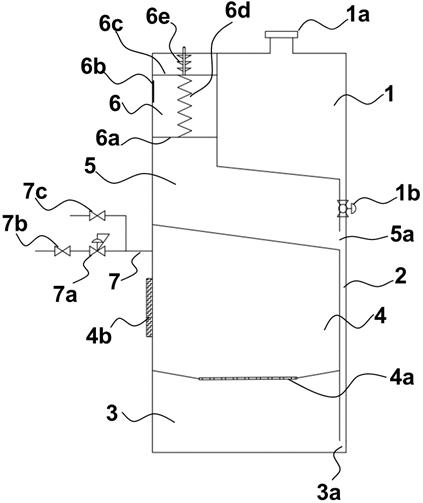

[0049] A first aspect of the invention, with figure 1 It is a structural schematic diagram of a low energy consumption pressure controllable hydrogen production and supply device of an embodiment of the present invention. The device includes a water tank (1), a water pipeline (2), a first water storage chamber (3), a reaction chamber (4), a second water storage chamber (5), a spring chamber (6), and an air pipeline ( 7). The hydrogen production process includes the following steps:

[0050] S1. Hydrogen-producing material filling step: open the switch door (4b) on the side of the reaction chamber (4), fill the hydrogen-producing material onto the filter plate (4a) at the bottom of the reaction chamber, and close the switch door after filling. In this example, the material for hydrogen production is block magnesium hydride.

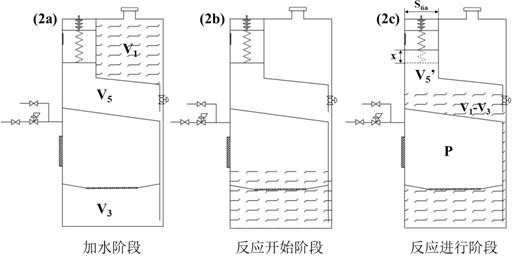

[0051] S2. Device setting steps: According to the required hydrogen production pressure, the volume of the aqueous solution to be added is obtained th...

Embodiment 2

[0058] In this embodiment, the first aspect of the present invention, the structure of a low-energy pressure controllable hydrogen production and supply device with a drain valve is as follows: Figure 4 shown. The device comes with figure 1 Compared with what is shown, a drainage pipeline (8) is added at the lower bottom of the outer side of the first water storage chamber (3), and a stop valve (8a) for controlling disconnection is provided on the pipeline. When the reaction is over or the user needs to stop hydrogen production for a long time during the reaction, the aqueous solution can be discharged by opening the stop valve (8a) on the drainage pipeline (8). This embodiment is especially suitable for relatively large-scale hydrogen production and hydrogen supply devices.

[0059] In this embodiment, the second aspect of the present invention, a structural block diagram of a portable fuel cell power generation system equipped with a gas-water separation device is shown ...

Embodiment 3

[0061] In this embodiment, the second aspect of the present invention, a structural block diagram of a portable fuel cell power generation system equipped with a gas-water separation device and a lithium battery is shown in the attached Image 6 shown. Due to the limitation of its own characteristics, the fuel cell has the problem of low transient response ability when it works independently as a power system, and cannot meet the stable power and fast transient response requirements required by most electronic devices. Moreover, the fuel cell also has disadvantages such as high cost, failure to recover braking energy, and frequent changes in the output state will damage the fuel cell and shorten its service life. Therefore, in this embodiment, a low-capacity lithium battery is added to cooperate with the fuel cell to form a stable power supply system to provide adjustable and fast-response power to variable loads.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com