An energy-saving gas pump group intermodal system and control method for complex gas drainage conditions

A technology of gas drainage and control methods, which is applied in the direction of separation methods, gas discharge, chemical instruments and methods, etc., can solve problems such as inability to realize intelligent regulation, affect the stable operation of pumps, and cut off flow of liquid supply, so as to achieve constant viscosity and stable Viscosity and purification, prolonging the trouble-free operation period, increasing the effect of gas drainage flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

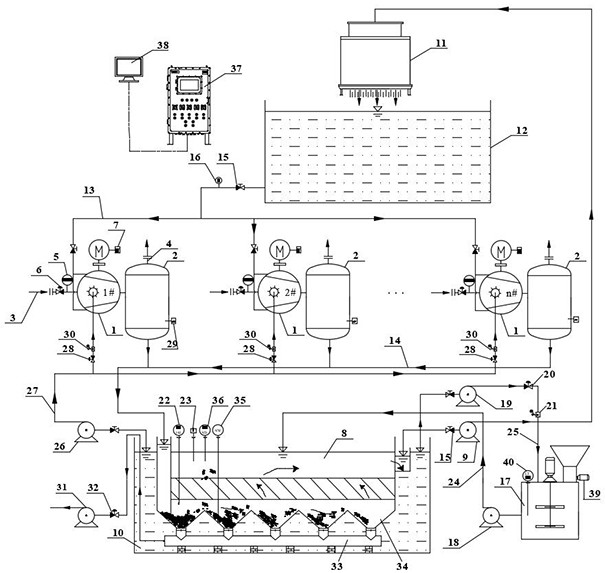

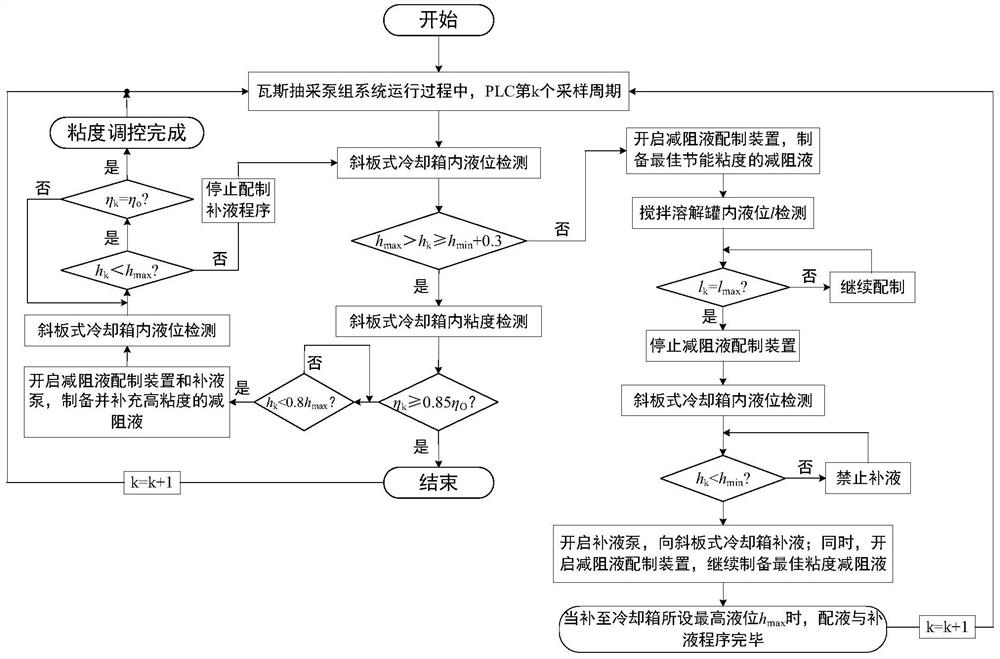

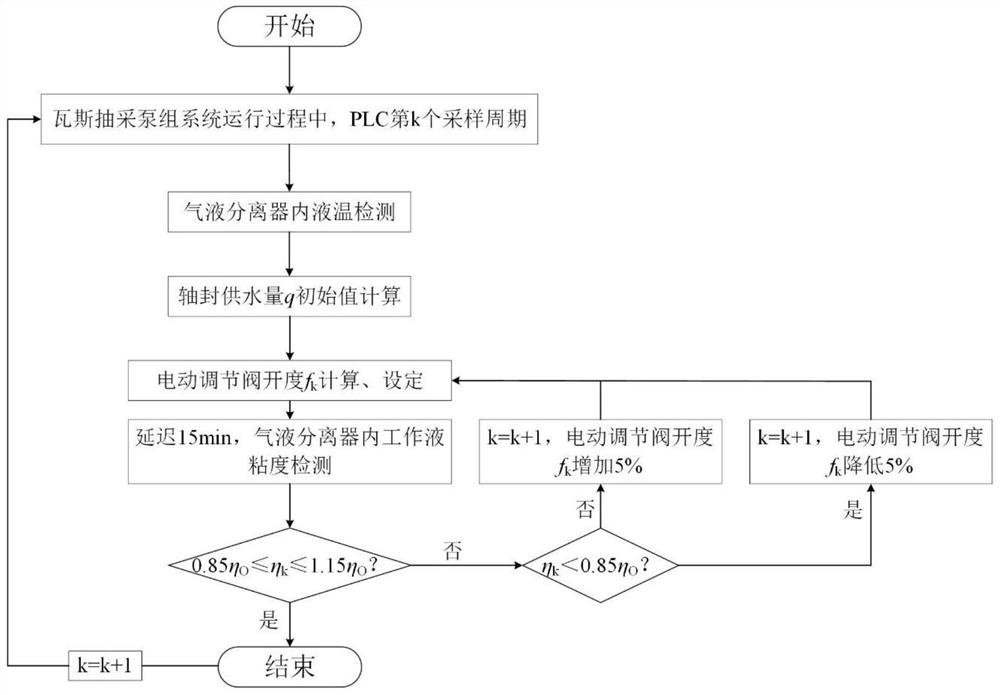

[0037] Such as figure 1 As shown, an energy-saving gas pump unit intermodal system for complex gas drainage conditions, including a gas drainage pump unit operation system, a working fluid circulation and cooling system, an integrated system for drag reduction and working fluid distribution, and an internal pump Adaptive constant viscosity system, working fluid intelligent purification system and pump group PLC monitoring substation.

[0038] The gas drainage pump operation system includes 2 to 20 gas drainage pumps 1 connected to each other, and each gas drainage pump 1 is sequentially installed with an air intake control valve 6 on the air intake pipeline 3 and a gas comprehensive parameter tester 5, each gas extraction pump 1 is connected to a gas-liquid separator 2, and the top exhaust port of the gas-liquid separator 2 is conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com