Coating for delaying corrosion of power system earth mat and preparation method of coating

A power system and coating technology, which is applied in the anti-corrosion coating and preparation field of the power system grounding grid, can solve the problems of polymer anti-aging performance to be improved, uneven protection area, unstable conductivity, etc., and achieve improvement The effect of safe operation guarantee level, long-term stability and good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

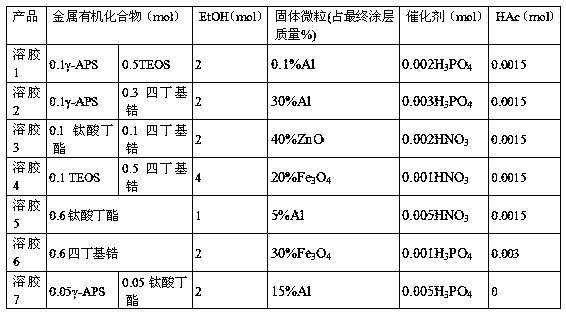

[0017] Control the temperature at 0~80℃, under stirring at 100~1000rpm, add the designed amount of ethanol, tetraethyl orthosilicate (TEOS) and catalyst in turn into the container, after the initial hydrolysis of TEOS, slowly add a certain amount of γ-ammonia Propyltriethoxysilane, as well as the designed variety and amount of solid particles, after the system is fully mixed, stir the mixture for 0.5~24h to make the mixture react, then stop stirring, let the mixture continue to react for 1~24h to become a sol. The raw material composition and usage amount of each specific sol are entered figure 1 shown.

Embodiment 2

[0019] Immerse the completely pre-treated metal grounding grid profile into any sol in Example 1, stay for a while (about 1~60min), and then smoothly move it from the The sol is extracted from the sol, and as the solvent volatilizes, the sol gels on the surface of the profile to form a film. Put it in the air at 0~60℃ and 80% relative humidity and fully dry it for 10min~4h, then transfer it to the heating furnace, under the protection of nitrogen atmosphere, control the heating rate at 5℃ / min, up to 125℃, and keep it warm 30min, then cool naturally.

[0020] The purpose of profile pretreatment is to completely remove the dirt and oxides attached to its surface and activate it. The main treatment methods include solvent degreasing, necessary pickling and cleaning steps, which can generally be carried out in accordance with the common methods of surface pretreatment of metal parts.

Embodiment 3

[0022] Coating methods can also be achieved by spraying, spin coating and brushing. The choice of coating method depends on the structure of the profile.

[0023] Spraying is suitable for structures that cannot be moved. When spraying, any sol in Example 1 is placed in the spray gun, and the compressed air with a pressure of 0.2~1.0MPa is used as the carrier gas. Spray on the surface of the structural parts that have been completely pre-treated, dry in the air for 10-20 minutes, spray the second layer as needed and repeat 3-4 times, and then put it in the air at 0-60 ℃ and 80% relative humidity for 10 minutes-4 hours After fully drying, use a local heating device to make the workpiece under the protection of nitrogen atmosphere, control the heating rate at 5°C / min, up to 125°C, keep it warm for 30min, and then cool it naturally.

[0024] Spin coating is suitable for flat profiles. When performing spin coating, fix the fully pretreated workpiece horizontally on the rotating de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com