A kind of amphoteric adsorption material with salt resistance and its preparation method and application

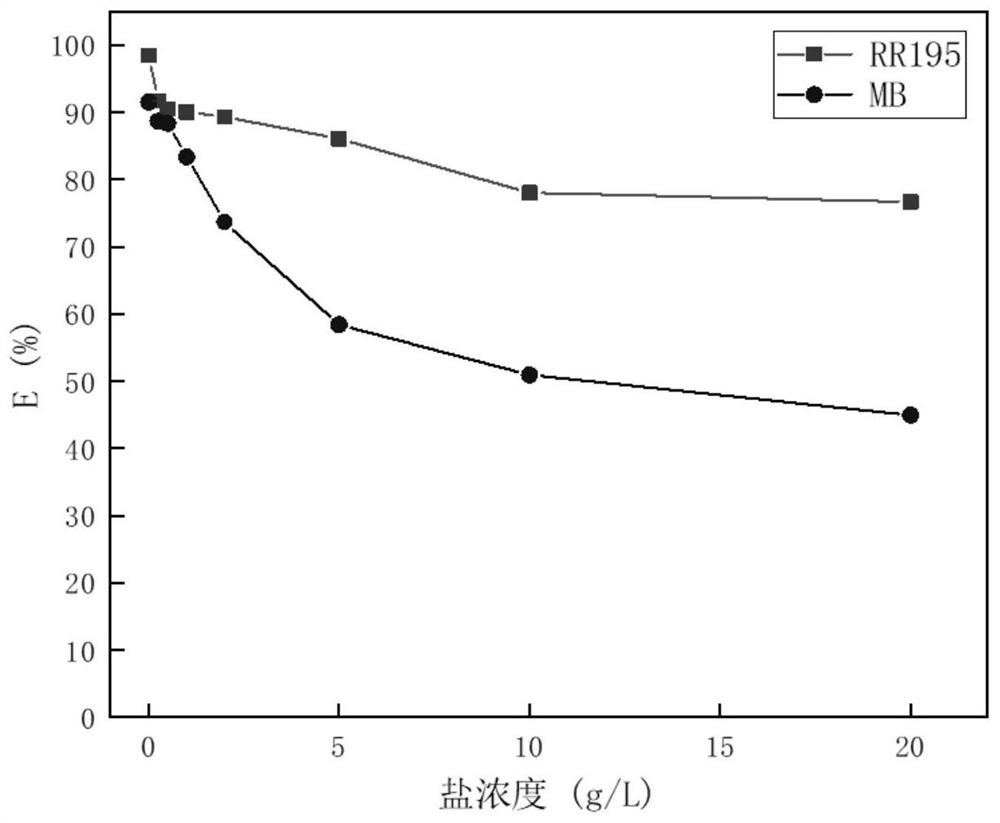

A technology of adsorption material and salt resistance, applied in the field of intelligent polymer materials, can solve the problems of limited application and decreased adsorption performance, and achieve the effect of excellent adsorption performance, excellent salt resistance and good adsorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

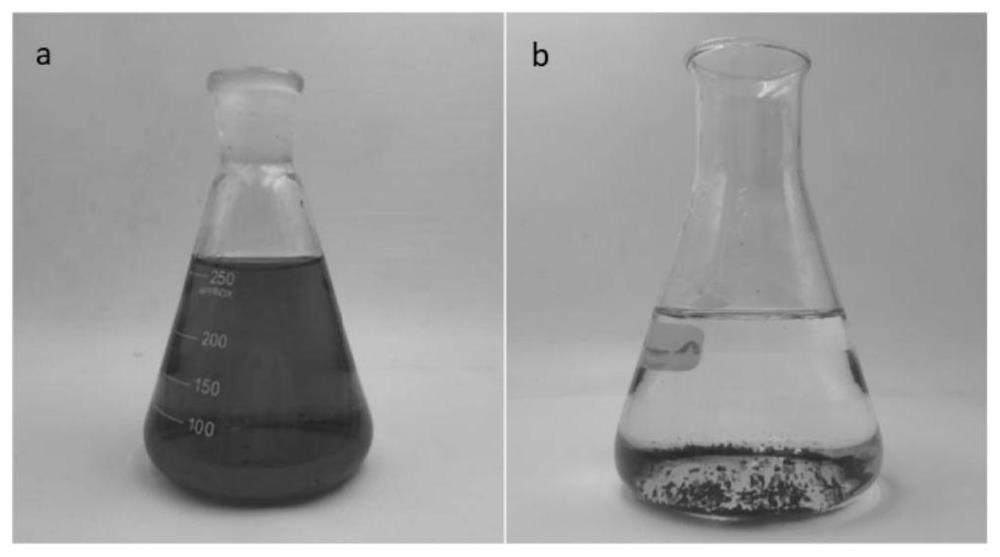

Image

Examples

preparation example Construction

[0029] One embodiment of the present invention proposes a preparation method of an amphoteric adsorption material with salt resistance, comprising the following steps:

[0030] Add maleic acid (MA), acrylamide (AM), dimethylaminoethyl methacrylate (DMAEMA) to the polyvinyl alcohol (PVA) solution, after the first mixing, add the crosslinking agent, the second mixing Finally, add initiator to obtain hydrogel prepolymerization solution;

[0031] The above-mentioned hydrogel prepolymerization solution is reacted under constant temperature conditions to obtain an amphoteric adsorption material.

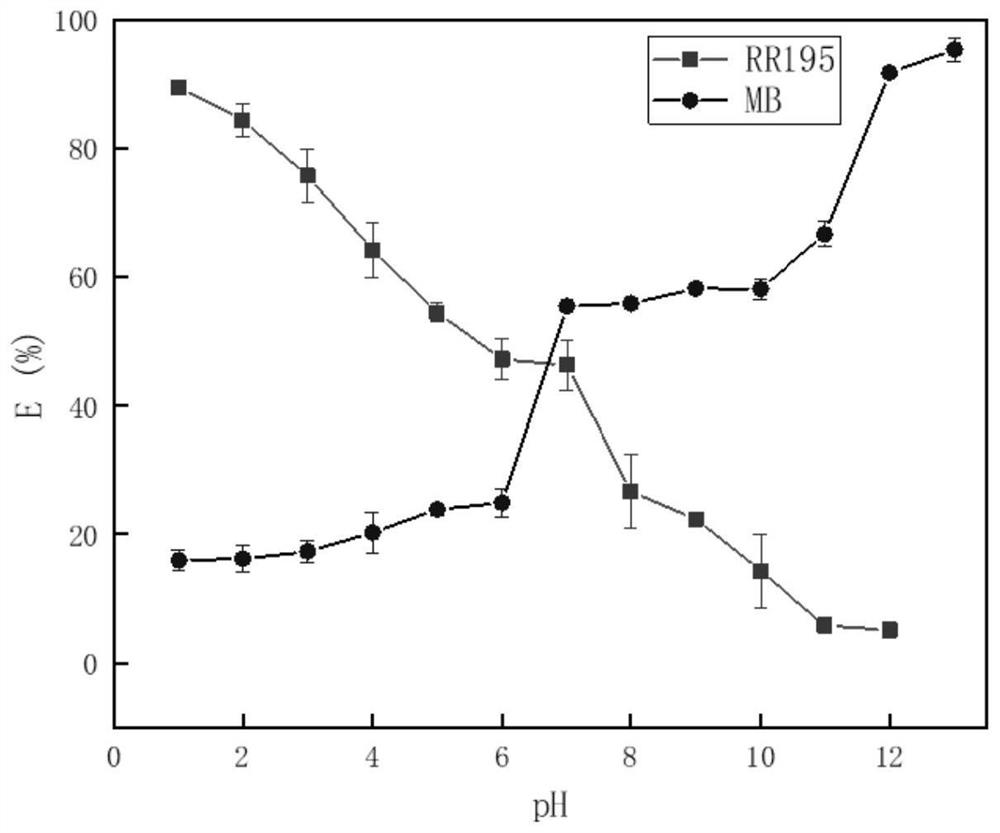

[0032] The embodiment of the present invention proposes a preparation method of an amphoteric adsorption material with salt resistance, mixing PVA solution with monomers MA, AM, and DMAEMA, and forming a hydrogel prepolymerization solution under the action of a crosslinking agent and an initiator , after a constant temperature heating reaction, a porous double network hydrogel is formed, ...

Embodiment 1

[0052] Example 1 A kind of preparation method of amphoteric adsorption material (PVA / MA / AM / DM), comprises the steps:

[0053] ① First, add 1g of MA, 1g of AM and 2g of DMAEMA to 20ml of PVA solution with a mass fraction of 5%, and then magnetically stir for 3 minutes to form a homogeneous solution, then add 0.16g of cross-linking agent BIS, and continue to magnetically stir for 5 minutes to form a homogeneous solution After adding 0.027g initiator K 2 S 2 o 8 , after stirring for 10 s, a homogeneous hydrogel prepolymer solution was obtained.

[0054] ② Inject the hydrogel pre-polymerization solution in ① into a 4ml centrifuge tube mold and seal it, then place it in a constant temperature water bath for reaction, set the temperature at 70°C, and after 2 hours, the porous double-network hydrogel will be cross-linked and formed.

[0055] ③ Cool the hydrogel in ② for 12 hours, put it into deionized water and purify it for 7 days, and dry the purified hydrogel at 60°C to obtai...

Embodiment 2

[0056] Example 2 A kind of preparation method of amphoteric adsorption material

[0057] ① First, add monomer 0.6g MA, 0.6g AM and DMAEMA 1.256g to 15ml of PVA solution with a mass fraction of 5%, and then magnetically stir for 2min to form a homogeneous solution. After homogeneous solution, add 0.027g initiator K 2 S 2 o 8 , after stirring for 10 s, a homogeneous hydrogel prepolymer solution was obtained.

[0058] ② Inject the homogeneous hydrogel pre-polymerization solution into a 12-well cell culture plate and seal it, and react at 65°C for 3 hours to form a porous double-network hydrogel.

[0059] ③ same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com