Spraying robot control system capable of automatically controlling spraying thickness

A technology of automatic thickness control and spraying robot, which is applied in the cleaning method using gas flow, spraying room, spraying device, etc. The effect of saving paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

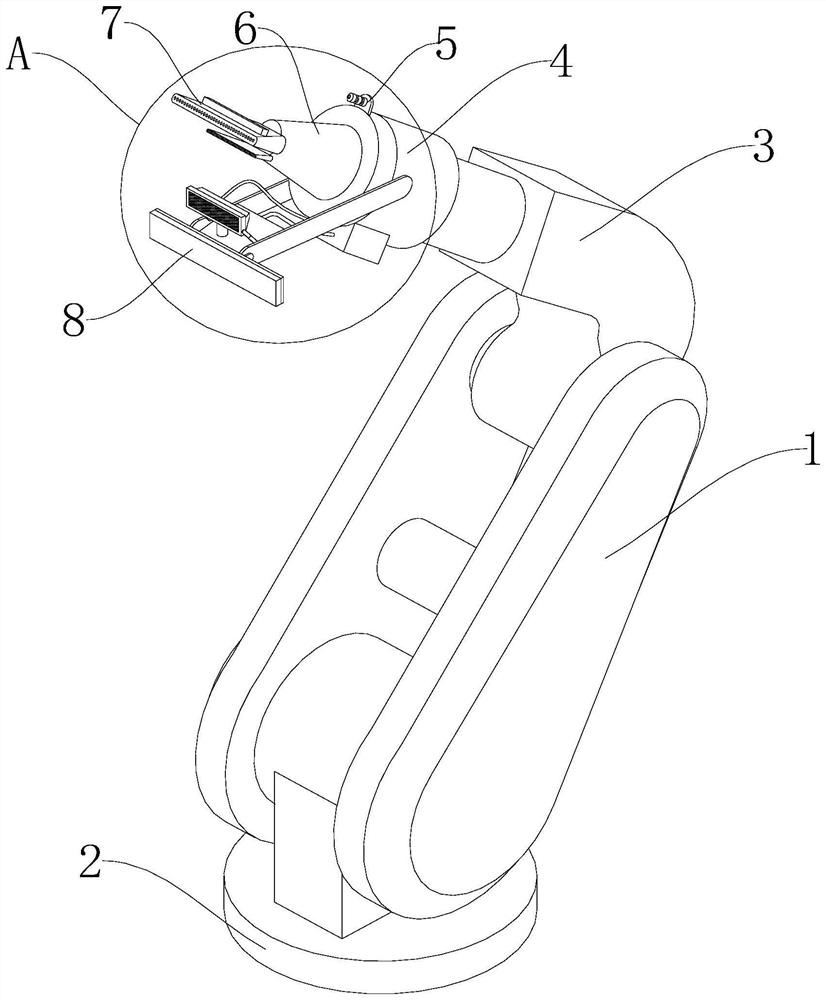

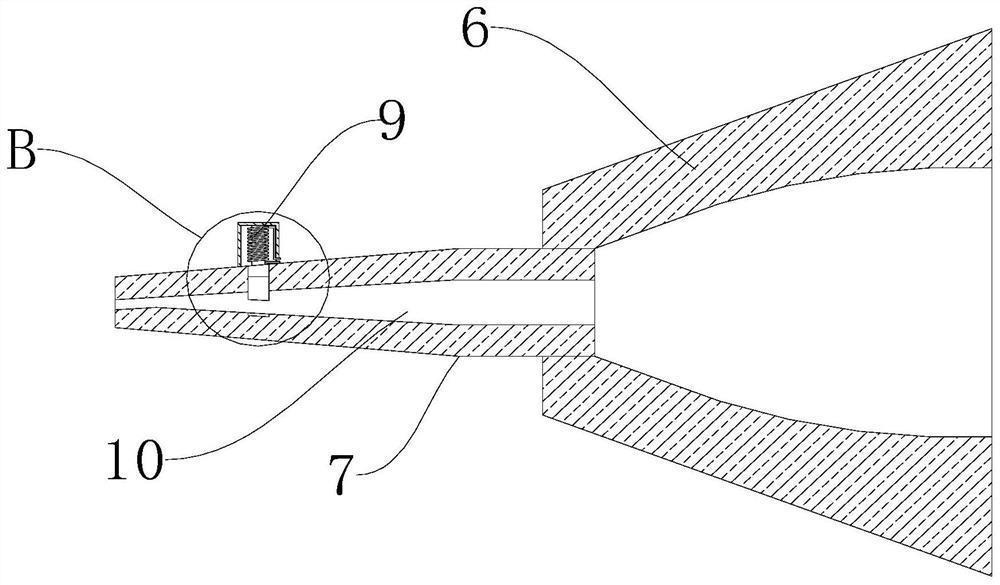

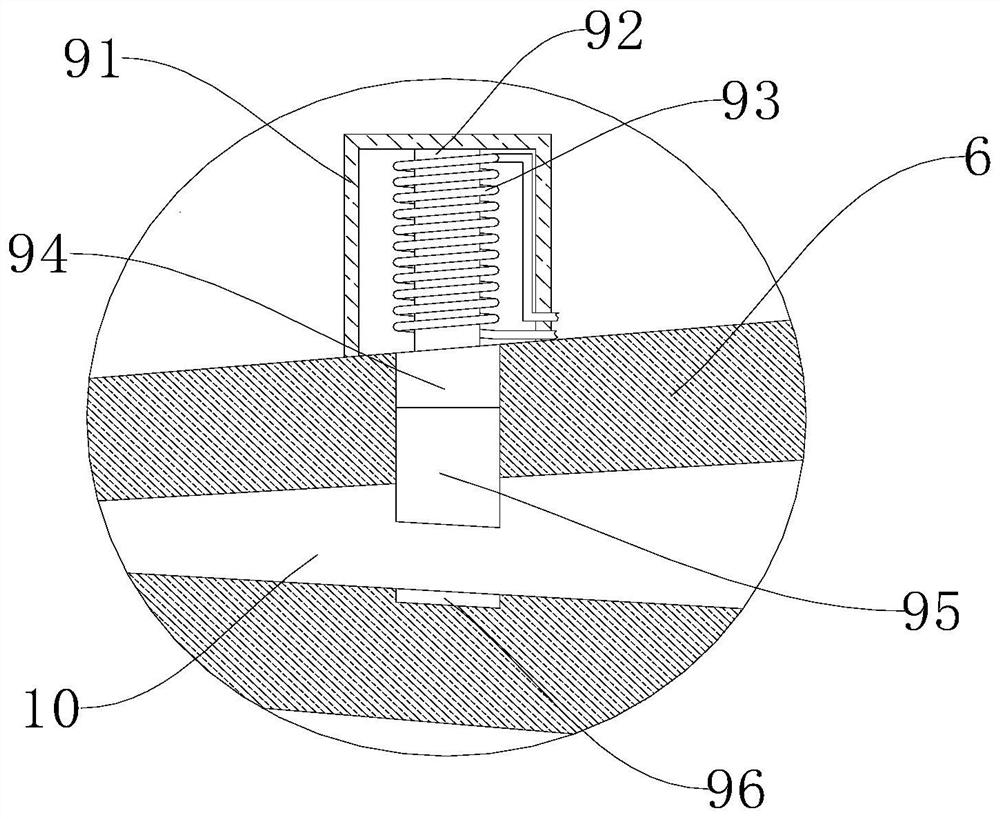

[0026] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, a spraying robot control system with automatic control of spraying thickness of the present invention includes a mechanical main arm 1, a rotating base 2 positioned at the bottom of the mechanical main arm 1, a second-section mechanical arm 3 positioned at the top of the mechanical main arm 1, and movably connected to the The mechanical wrist 4 at the front end of the second-stage mechanical arm 3, the top of the mechanical wrist 4 is fixedly provided with a detection probe 5, the front end of the mechanical wrist 4 is connected with a feeding pipe 6, and the front end of the feeding pipe 6 is fixedly provided with a duckbill nozzle 7, The front end of the duckbill nozzle 7 is provided with a coating spray hole 10 communicated with the feeding pipe 6, and the top of the duckbill nozzle 7 is provided with a nozzle control structure 9, which includes an anti-corrosion devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com