Preparation method of kelp-shaped silver structure

A kelp and nano-silver technology is applied in metal processing equipment, nanotechnology for materials and surface science, transportation and packaging, etc. It can solve the problem of no kelp-like silver micro-nano structure, and achieve low cost and simple process. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of kelp-shaped silver structure, comprising the following steps:

[0027] S1. Prepare a mixed solution of 0.75M hydrofluoric acid, 0.03M silver nitrate and 0.005M SDS;

[0028] S2. Soak the silicon wafer in the mixed solution prepared in step S1;

[0029] S3, react for 5 minutes, rinse the silicon wafer, and dry it with nitrogen.

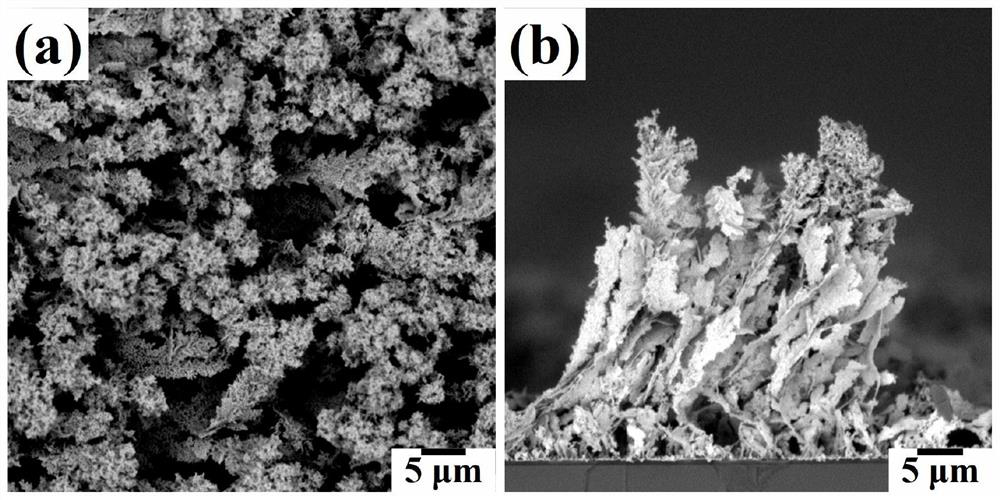

[0030] Prepare the kelp-shaped silver structure according to the above steps, figure 1 It is the scanning electron micrograph of the kelp-shaped silver structure.

Embodiment 2

[0032] A preparation method of kelp-shaped silver structure, comprising the following steps:

[0033] S1. Prepare a mixed solution of 0.75M hydrofluoric acid, 0.03M silver nitrate and 0.01M SDS;

[0034] S2. Soak the silicon wafer in the mixed solution prepared in step S1;

[0035] S3, react for 5 minutes, rinse the silicon wafer, and dry it with nitrogen.

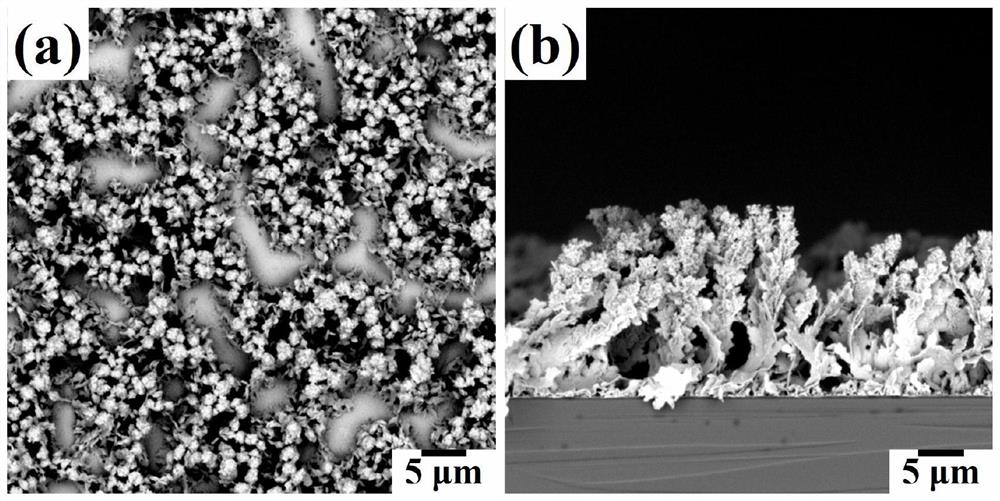

[0036] Prepare the kelp-shaped silver structure according to the above steps, figure 2 It is the scanning electron micrograph of the kelp-shaped silver structure.

Embodiment 3

[0038] A preparation method of kelp-shaped silver structure, comprising the following steps:

[0039] S1. Prepare a mixed solution of 0.75M hydrofluoric acid, 0.03M silver nitrate and 0.03M SDS;

[0040] S2. Soak the silicon wafer in the mixed solution prepared in step S1;

[0041] S3, react for 5 minutes, rinse the silicon wafer, and dry it with nitrogen.

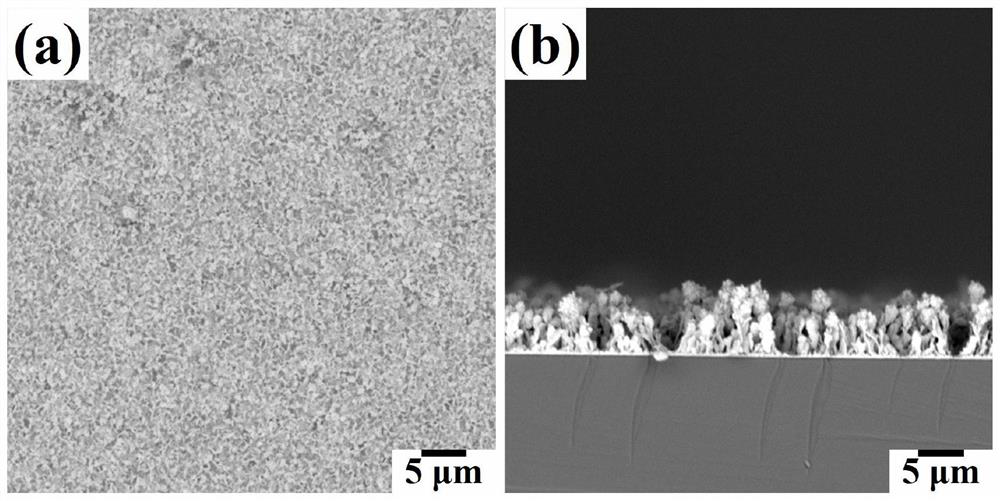

[0042] Prepare the kelp-shaped silver structure according to the above steps, image 3 It is the scanning electron micrograph of the kelp-shaped silver structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com