A processing system for steel pipe filling concrete

A processing system and concrete technology, which are applied in the directions of mixing operation control, clay preparation device, mixing operation control device, etc., can solve the problems of low degree of processing automation, difficult expansion agent, and inability to meet production and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further describe the present invention, a concrete implementation of a steel pipe filling concrete processing system will be further described below in conjunction with the accompanying drawings. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

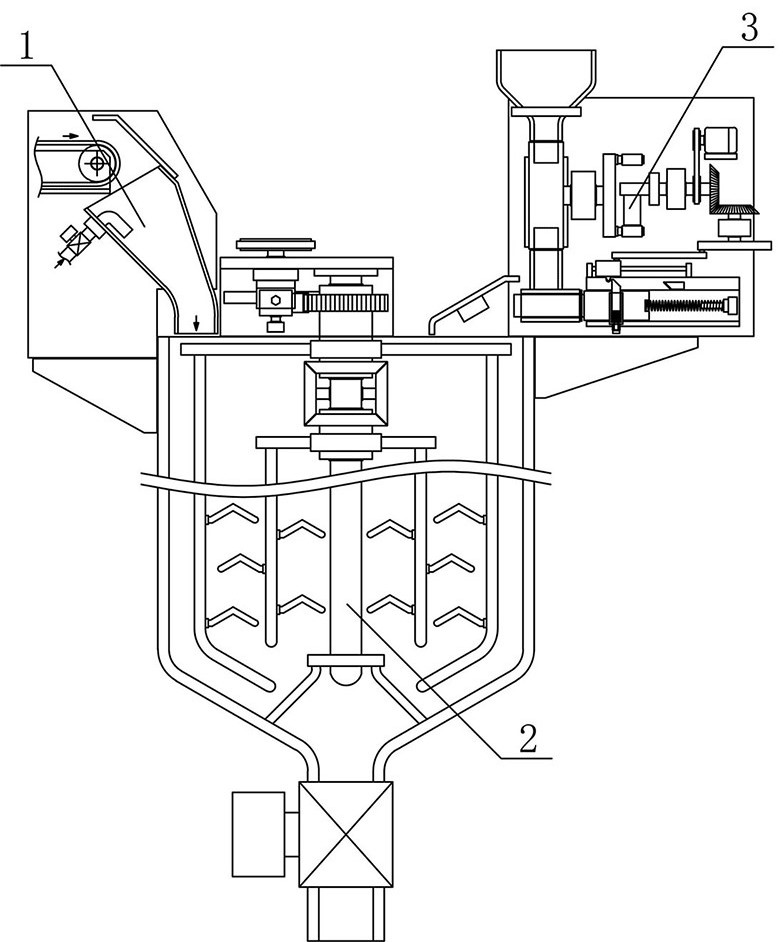

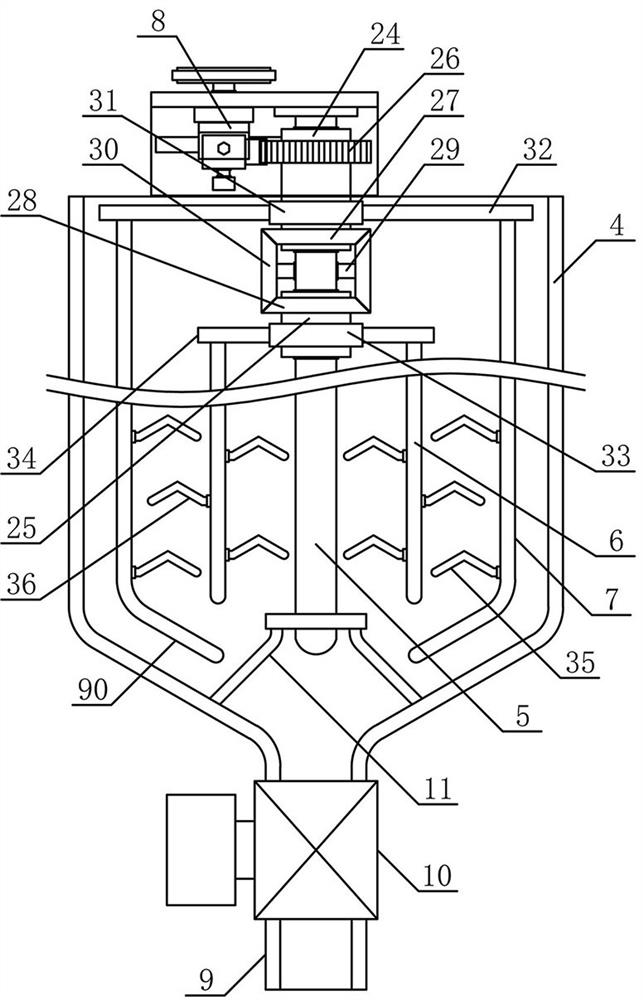

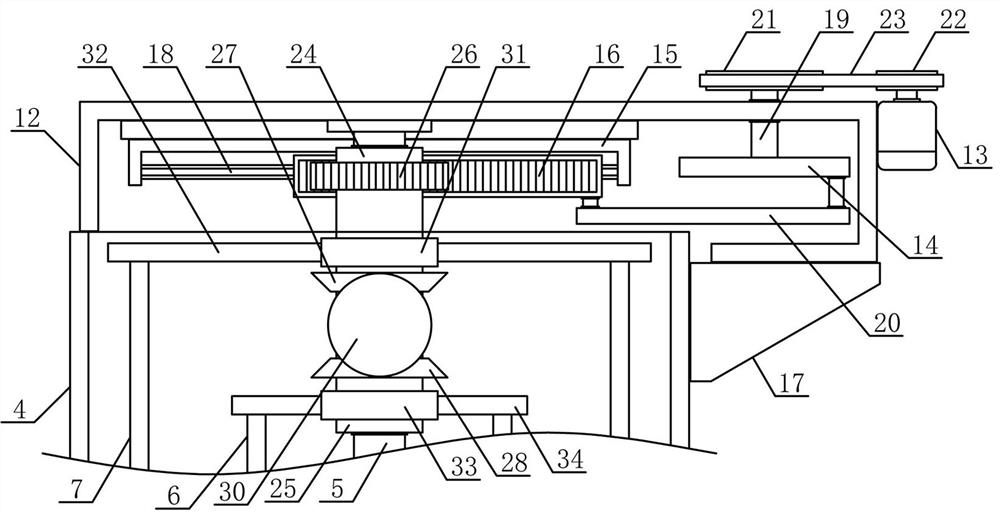

[0028] Such as figure 1 As shown, a processing system for concrete filled with steel pipes in the present invention includes a main material transmission mechanism 1, a processing and mixing mechanism 2, and an auxiliary material filling mechanism 3, and the main material transmission mechanism 1 and the auxiliary material filling mechanism 3 are respectively arranged on the processing and mixing mechanism 2 top sides, such as figure 2 with image 3As shown, the processing and stirring mechanism 2 of the present invention includes a preparation stirring tank 4, a stirring support column 5, an inner stirring rod 6 for processing, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com