Low-temperature economizer system with leakage detection function and control method

A low-temperature economizer and leak detection technology, which is applied in the direction of control of feed water, feed water heaters, lighting and heating equipment, etc., can solve the problems of low-temperature economizers without reliable leak detection means, so as to improve reliability and economy, Avoid dust blocking, reliable leak detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in further detail below in conjunction with accompanying drawing:

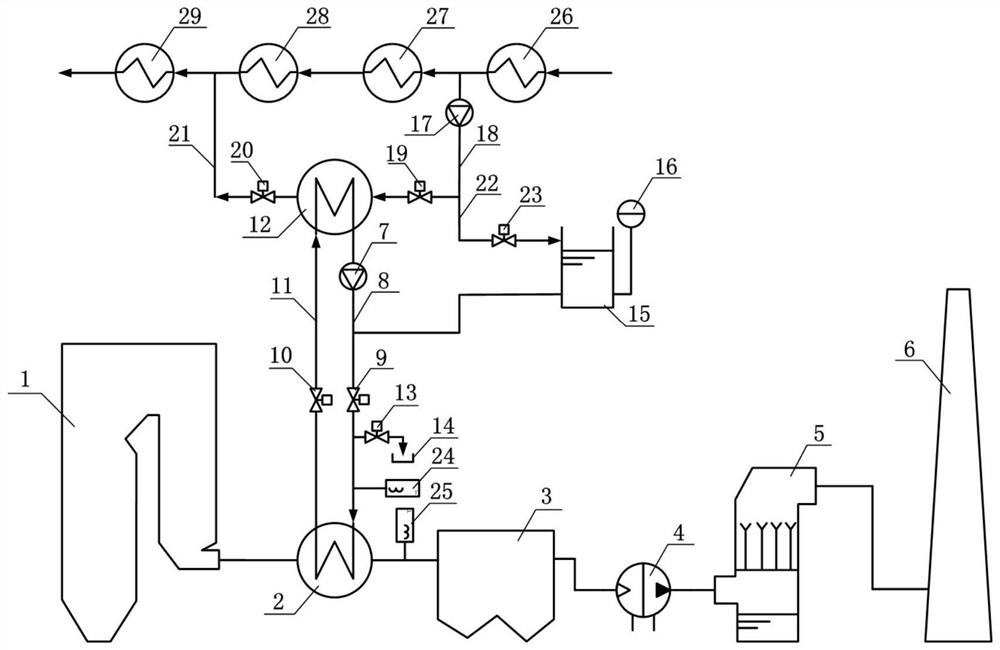

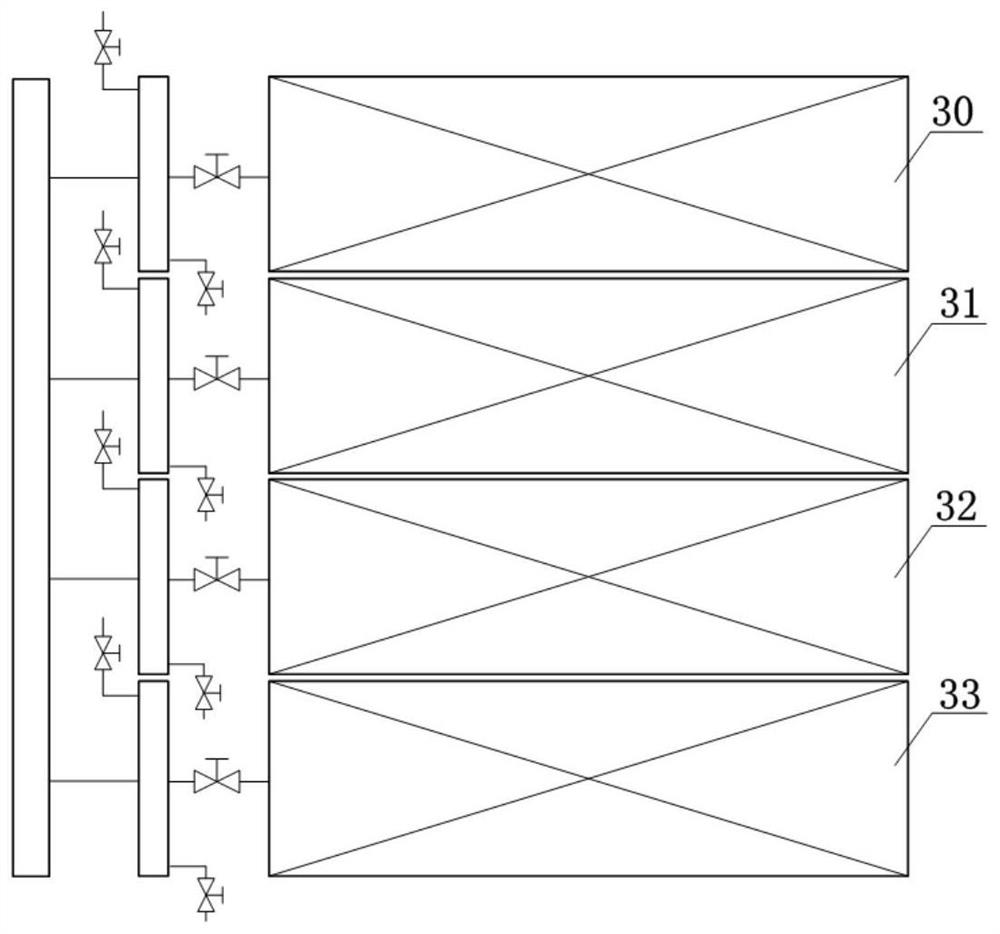

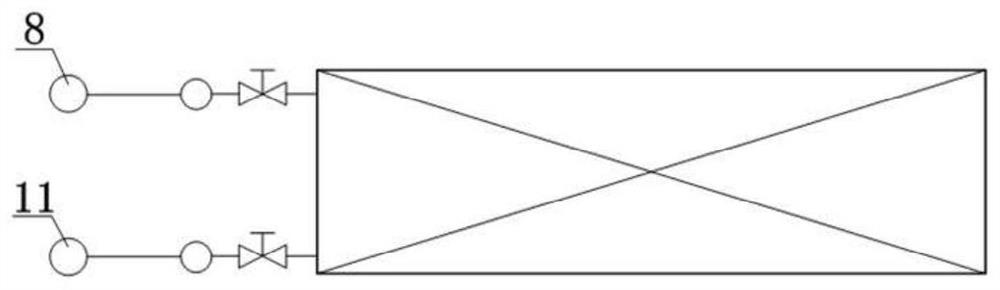

[0024] refer to figure 1 , a low-temperature economizer system with a leak detection function according to the present invention, including a boiler body 1, a low-temperature economizer 2, a dust collector 3, an induced draft fan 4, a desulfurization tower 5, a chimney 6, a frequency conversion circulation pump 7, Circulating water inlet pipe 8, circulating water inlet shut-off valve 9, circulating water outlet shut-off valve 10, circulating water outlet pipe 11, condensate heater 12, drain valve 13, trench 14, water tank 15, water tank level gauge 16, Frequency conversion booster pump 17, condensate inlet pipe 18, condensate inlet shut-off valve 19, condensate outlet shut-off valve 20, condensate outlet pipe 21, water supply branch 22, water supply shut-off valve 23, circulating water inlet temperature measurement Point 24, low-temperature economizer outlet flue gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com