Fertilizer coating sustained-release agent and application method thereof

A fertilizer coating and slow-release agent technology, which is applied in fertilization methods, fertilizer mixtures, layered/coated fertilizers, etc., can solve problems such as increased labor intensity, large concentration differences, and inability to reduce fertilizer loss, so as to avoid residues , Improve the effect of penetration uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

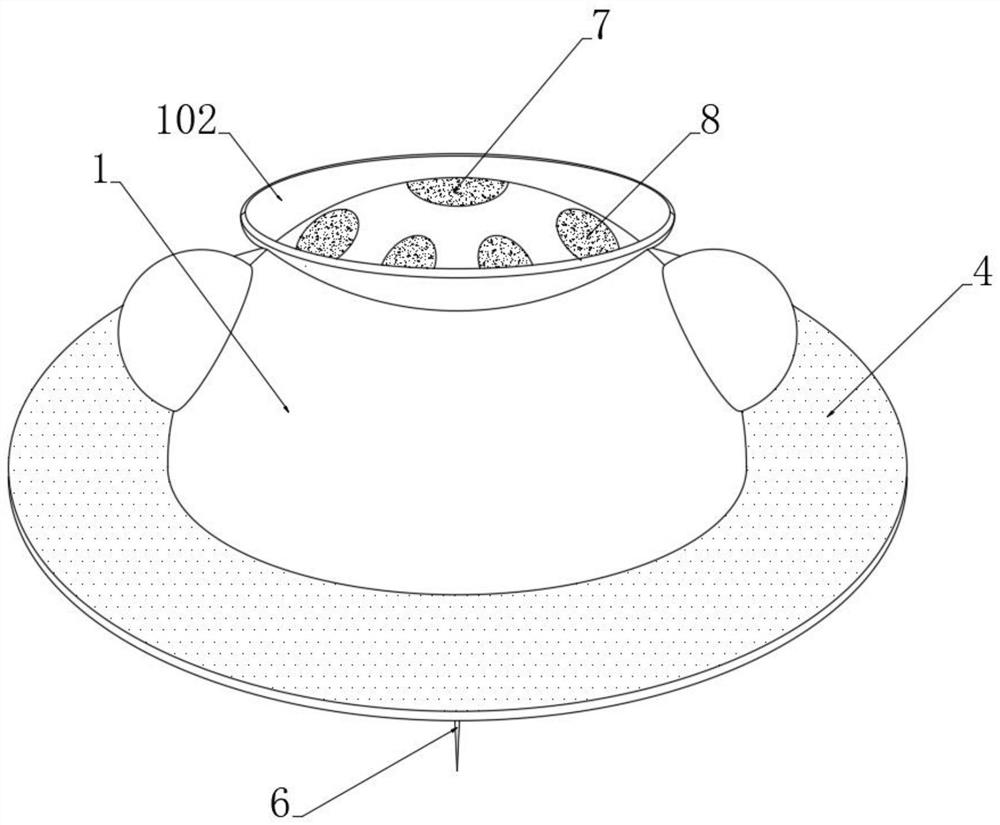

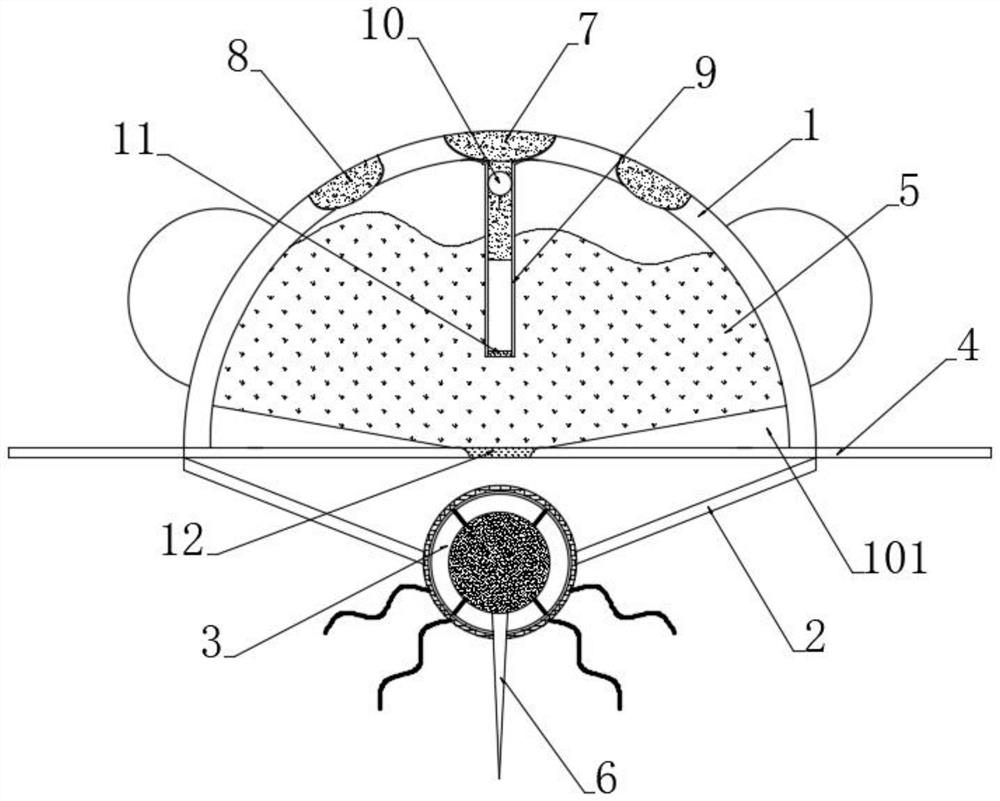

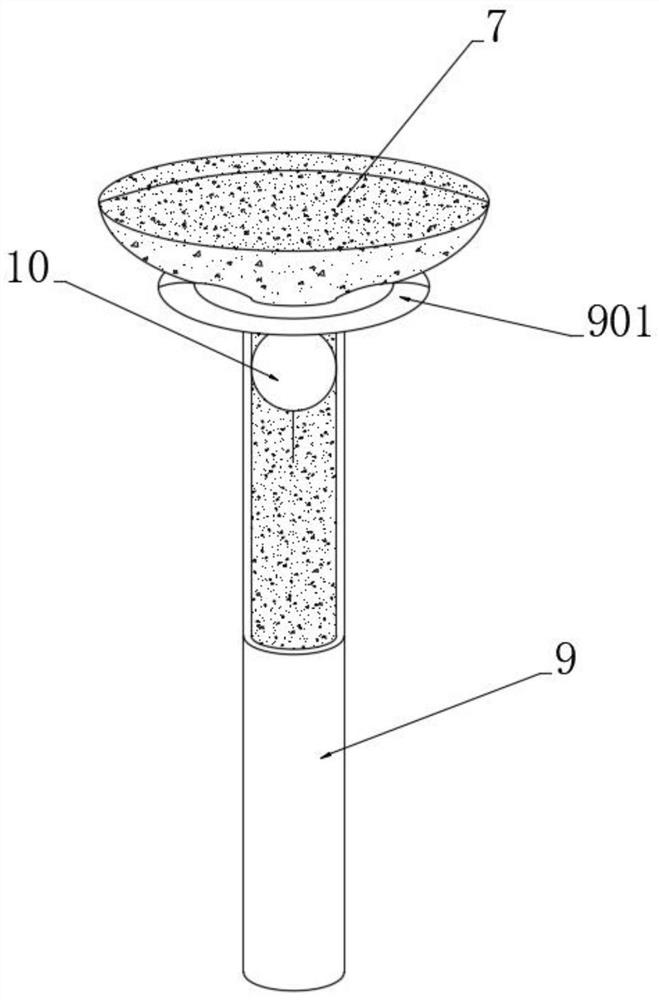

[0044]SeeFigure 1-4 , A fertilizer coated slow-release agent, comprising an oval coated shell 1 and a tapered slow-release body 2 arranged up and down, and a coating layer 4 is arranged between the oval coated shell 1 and the cone-shaped slow-release body 2 The coating layer 4 includes an impermeable layer 401 located between the oval envelope 1 and the tapered sustained-release body 2. A water-absorbing layer 402 is provided on the outer side of the impermeable layer 401, and the water-absorbing layer 402 is located in the oval envelope 1 The inside of the oval coating shell 1 is filled with fertilizer 5. The fertilizer 5 is preferably organic fertilizer. The anti-seepage layer 401 is provided with a permeable material port, and the lower film 12 is provided at the permeable material port. A cone-shaped diversion platform 101 at the top end of the impermeable layer 401 is installed at the bottom end of the cone. The bottom end of the cone-shaped diversion platform 101 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com