A kind of equipment for dehydrating fruits and vegetables through chocolate penetration and its production method

A chocolate, fruit and vegetable technology, applied in the field of food processing, can solve the problems of non-presentation, difficult control of porosity, unevenness, etc., and achieve the effect of reducing operating costs, reducing investment costs, and high penetration uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

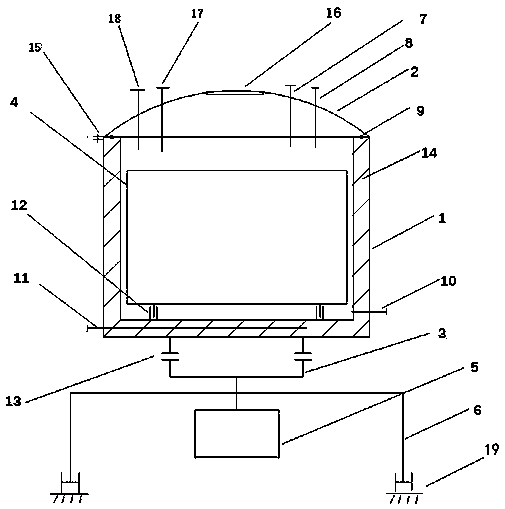

[0042] Step a: Open the rotating barrel lid 2, add freeze-dried taro strips into the material barrel 4, the amount added is 2 / 3 of the volume of the material barrel 4, close and lock the rotating barrel lid 2, and carry out without touching the chocolate solution. Reduce the pressure to an absolute pressure of 10Pa;

[0043]Step b: After maintaining the vacuum state described in step a for 5 minutes, inject the melted chocolate solution into the rotating barrel 1 under the vacuum state, so that the height of the melted chocolate solution is higher than the height of the dehydrated fruits and vegetables, preferably making the melted chocolate Solution is close to the height of material bucket 4;

[0044] Step c: Keep the vacuum degree in the rotating barrel 1 at 100Pa, the temperature at 35°C, after 0.5h, slowly break the vacuum through the vacuum breaking valve 7, and return to normal pressure, and the recovery time is 10 minutes;

[0045] Step d: extract most of the uninfilt...

Embodiment 2

[0055] Step a: Open the rotating barrel lid 2, add freeze-dried taro strips into the material barrel 4, the amount added is 2 / 3 of the volume of the material barrel 4, close and lock the rotating barrel lid 2, and carry out without touching the chocolate solution. Decompress to an absolute pressure of 1000Pa;

[0056] Step b: After maintaining the vacuum state described in step a for 60 minutes, inject the melted chocolate solution into the rotating barrel 1 under the vacuum state, so that the height of the melted chocolate solution is higher than the height of the dehydrated fruits and vegetables, preferably making the melted chocolate Solution is close to the height of material bucket 4;

[0057] Step c: Keep the vacuum degree in the rotating barrel 1 at 1500 Pa, the temperature at 40°C, after 5 hours, slowly break the vacuum through the vacuum breaking valve 7, and return to normal pressure, and the recovery time is 20 minutes;

[0058] Step d: extract most of the uninfilt...

Embodiment 3

[0068] Step a: Open the rotating barrel lid 2, add freeze-dried taro strips into the material barrel 4, the amount added is 2 / 3 of the volume of the material barrel 4, close and lock the rotating barrel lid 2, and carry out without touching the chocolate solution. Decompress to an absolute pressure of 700Pa;

[0069] Step b: After maintaining the vacuum state described in step a for 40 minutes, inject the melted chocolate solution into the rotating barrel 1 under the vacuum state, so that the height of the melted chocolate solution is higher than the height of the dehydrated fruits and vegetables, preferably making the melted chocolate Solution is close to the height of material bucket 4;

[0070] Step c: Keep the vacuum degree in the rotating barrel 1 at 1000 Pa, the temperature at 37°C, after 3 hours, slowly break the vacuum through the vacuum breaking valve 7, and return to normal pressure, and the recovery time is 17 minutes;

[0071] Step d: extract most of the uninfiltr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com