Fabricated building floor heat preservation and sound insulation integrated plate and construction method thereof

A floor-to-floor, prefabricated technology, applied in the field of integrated slabs and its construction, can solve problems such as inability to effectively reduce labor, uneconomical and practical, and difficult construction, and meet the requirements for thermal insulation and sound insulation, suitable for popularization and application, and economical The effect of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

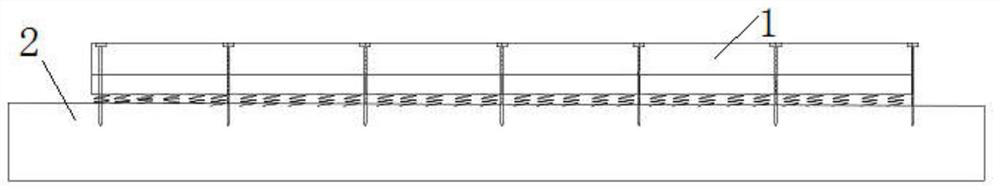

[0019] Such as figure 1 , multiple prefabricated panels 1 are spliced together, the fixing device 3 is a leveling anchor bolt, and the prefabricated panel 1 is fixed on the floor 2 through the leveling anchor bolt.

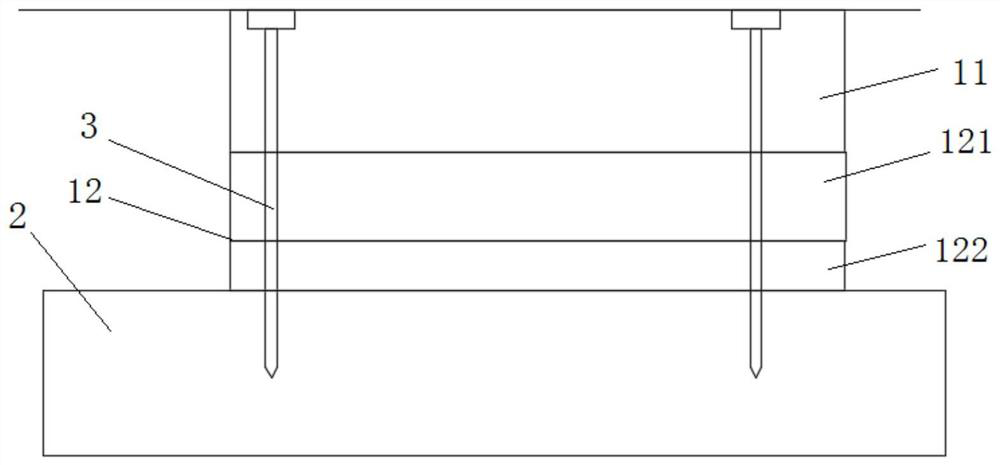

[0020] Such as figure 2 , the prefabricated panel 1 is prefabricated by a factory, and the functional layer 12 includes a sound insulation layer 121 and a thermal insulation layer 122 . The protective surface layer 11, the sound insulation layer 121, and the thermal insulation layer 122 are fixedly connected sequentially from top to bottom. The size of the prefabricated panel 1 is generally 300×300mm 2 , 400×400mm 2 , 500×500mm 2 , 600×600mm 2 , 700×700mm 2 , 800×800mm 2 or 300×600mm 2 , 300×1200mm 2 Wait. The thickness of the protective surface layer 11 is 5-50 mm, and the material is made of cementitious materials (cement, gypsum, etc.) Function: The protective surface layer 11 can be made of calcium silicate board, fiber cement board, cement press...

Embodiment 2

[0025] A plurality of prefabricated panels 1 are spliced together, and the fixing devices 3 are positioning anchors or positioning screws, which are evenly spaced on the prefabricated panels 1, and the prefabricated panels 1 are fixed on the floor 2 by positioning anchors or positioning screws. Positioning screws can be metal expansion screws, plastic expansion screws, expansion bolts, straight nails, self-tapping screws, shooting nails and other fixing screws.

[0026] The prefabricated panel 1 is prefabricated by a factory, and the functional layer 12 includes an insulating layer 122 . The protective surface layer 11 and the insulation layer 122 are fixedly connected sequentially from top to bottom, and the surface of the insulation layer 122 has grooves for laying water heating pipes or electric heating pipes. The size of the prefabricated panel 1 is generally 300×300mm 2 , 400×400mm 2 , 500×500mm 2 , 600×600mm 2 , 700×700mm 2 , 800×800mm 2 or 300×600mm 2 , 300×120...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com