Manufacturing method of MOS control thyristor

A manufacturing method and thyristor technology, which is applied in the direction of thyristor, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as difficulty in accurately controlling device channel doping concentration and length, failure to meet pulse power and solid-state circuit breaker application requirements, etc. , to achieve the effects of easy popularization and utilization, high current rise rate, and low on-state voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

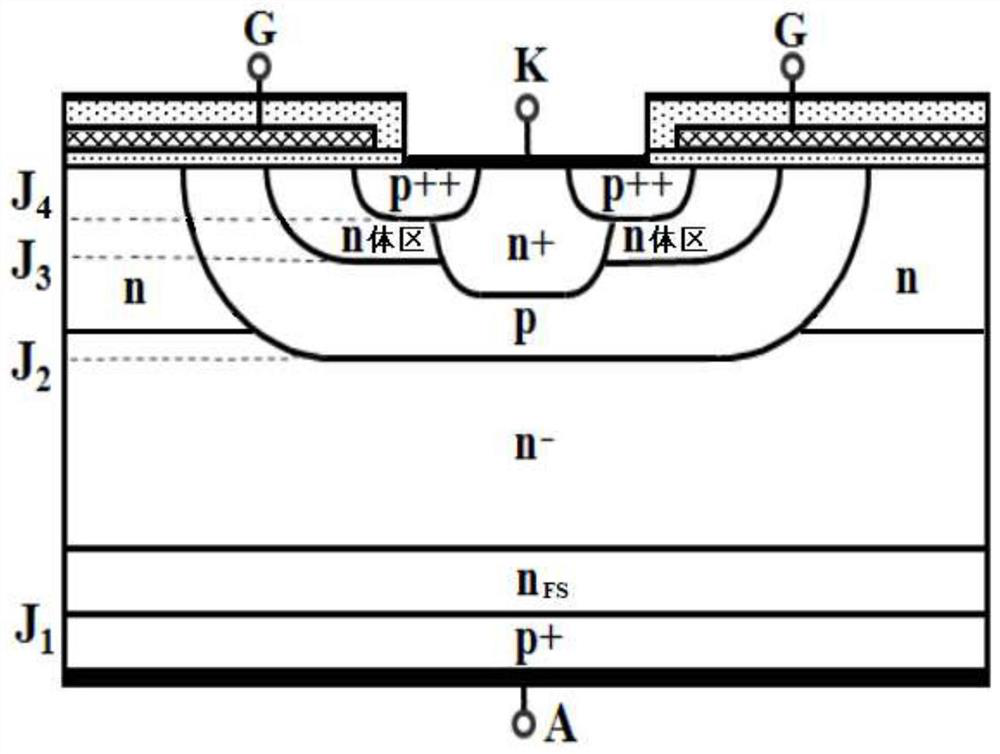

[0027] refer to figure 1 , the basic structure of the MOS control thyristor of the present invention is that the whole device is n - The drift region acts as a voltage-resistant layer, n - There is a p base area in the center above the drift region, and n areas are located on both sides of the p base area; an n area is set in the center above the p base area. + Cathode area, n + There are n body regions on both sides of the cathode region, and the n body regions on both sides and n + A p ++ source region; two p ++ The aluminum layer on the upper surface of the source region and the n + The aluminum layer on the upper surface of the cathode region is connected as a whole to form the cathode electrode K; the n region, p base region, n body region and part of the p region on both sides ++ A layer of gate oxide layer (i.e. SiO 2 Material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com