Sensor automatic patch assembly line and patch method

A sensor and assembly line technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of low sensor placement efficiency, poor product consistency, complicated operation process, etc., to achieve good product consistency, stability improvement, and operation process Simple and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

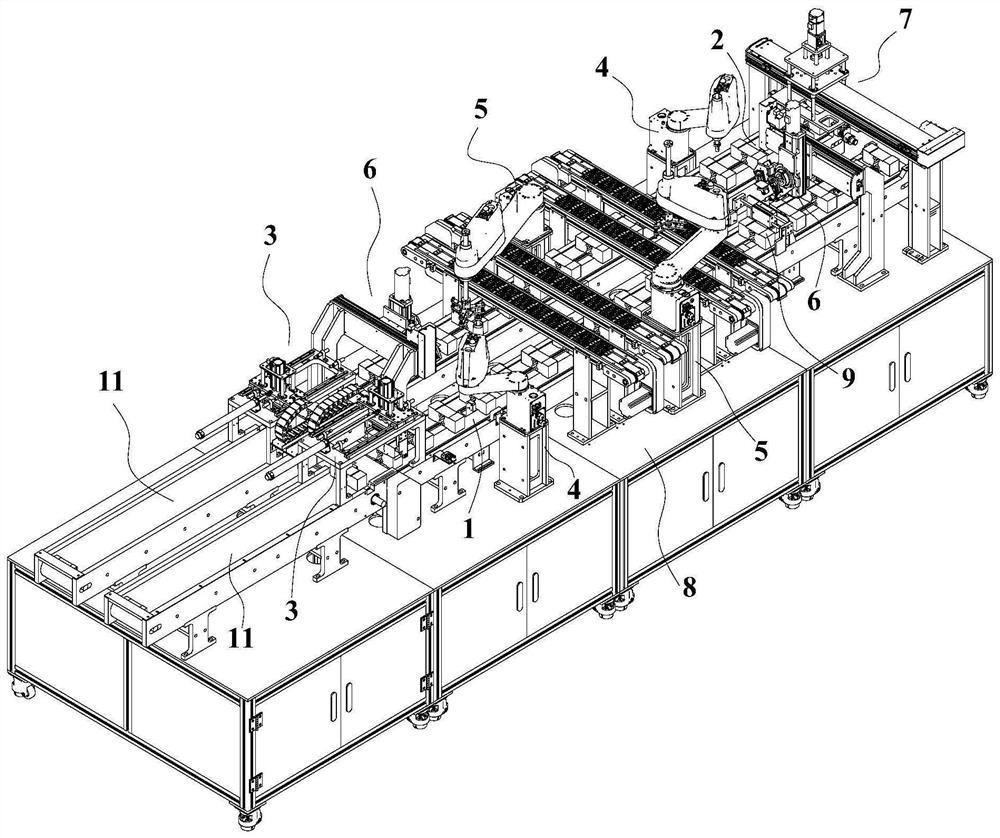

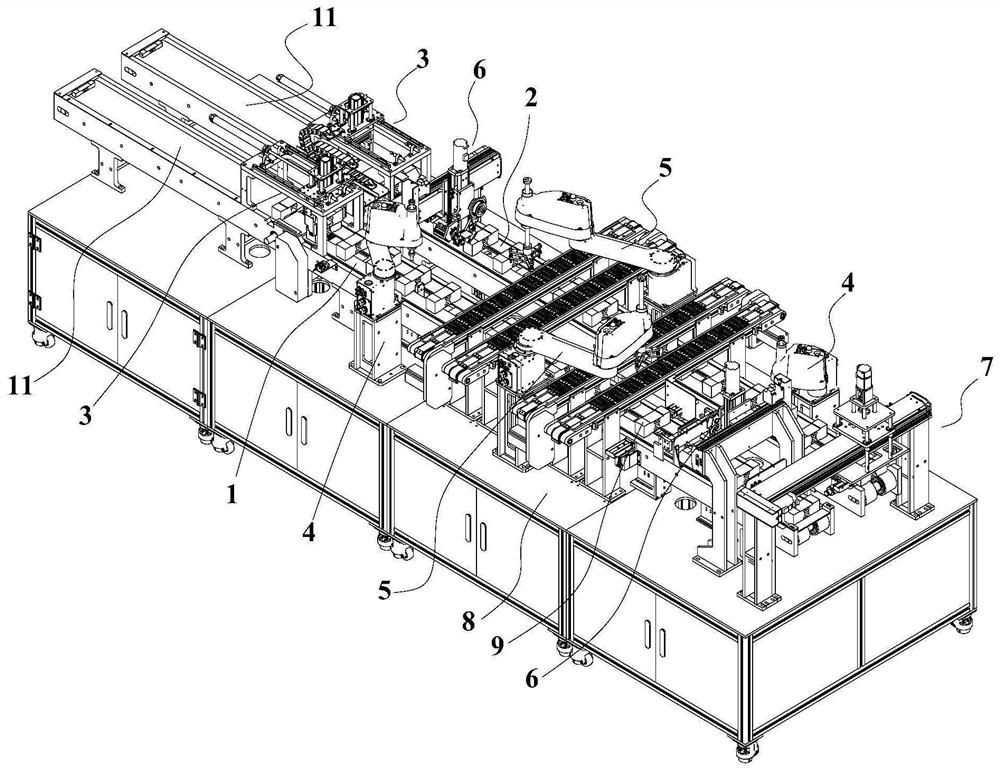

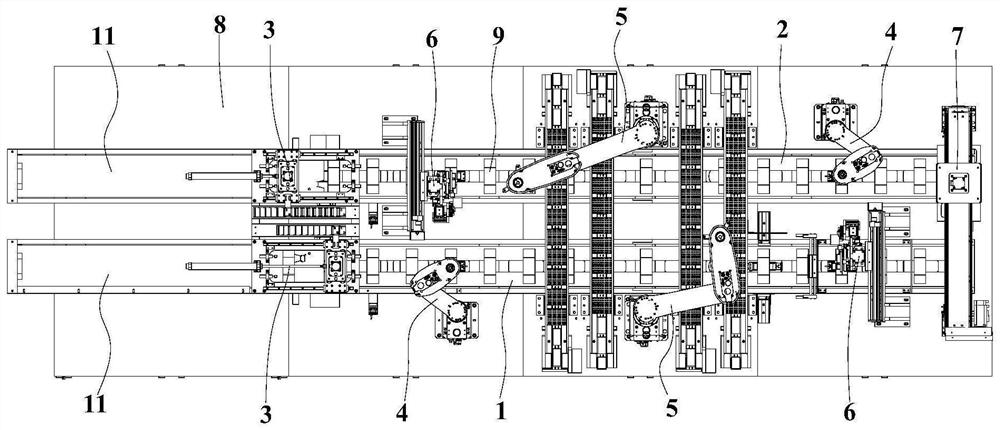

[0083] like Figure 1-3 As shown, a sensor automatic patch assembly line includes a first conveying mechanism 1, a second conveying mechanism 2, a material transfer mechanism 3, a glue spreading mechanism 4, a patch mechanism 5, a tape sticking mechanism 6, a handling and turning mechanism 7, a machine 8. Control unit.

[0084] In this embodiment, the main function of the frame 8 is to provide installation positions for the remaining components. The frame 8 is not limited to a specific shape, as long as the components can be installed and matched according to the requirements, and the corresponding functions can be realized. , the control unit in this embodiment adopts PLC, and PLC is an existing technology. Those skilled in the art can program it according to actual needs to realize the control function described in this embodiment. In this embodiment, the first The first conveying mechanism 1, the second conveying mechanism 2, the material transfer mechanism 3, the gluing m...

Embodiment 2

[0141] The present invention also discloses a patching method using the automatic sensor patching assembly line described in Embodiment 1, which includes the following steps:

[0142] A. Feeding: Place the sensor 9 on the material conveyor belt 11 in front of the first conveying mechanism 1, the material conveyor belt 11 continues to run, and the sensor 9 is delivered to the stopper 111, the material conveyor belt 11 slips, and the front continues to move The sensor 9 is placed on the material conveyor belt 11, and then the sensor 9 is continuously transported to the front of the previous sensor 9, thereby realizing the accumulation of multiple sensors 9 in front of the stopper 111;

[0143] The material transfer mechanism 3 transfers the sensor 9 to be patched to the feeding end of the first conveying mechanism 1 for loading, and the side of the sensor 9 to be patched faces upward;

[0144] B. Conveying at equal intervals: the first conveying mechanism 1 drives the sensor 9 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com