Anti-fog coating, anti-fog film and preparation method thereof

An anti-fog coating, water-based technology, applied in anti-fouling/underwater coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of limited improvement of product performance, achieve high production efficiency, improve wear resistance, The effect of good anti-fog performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

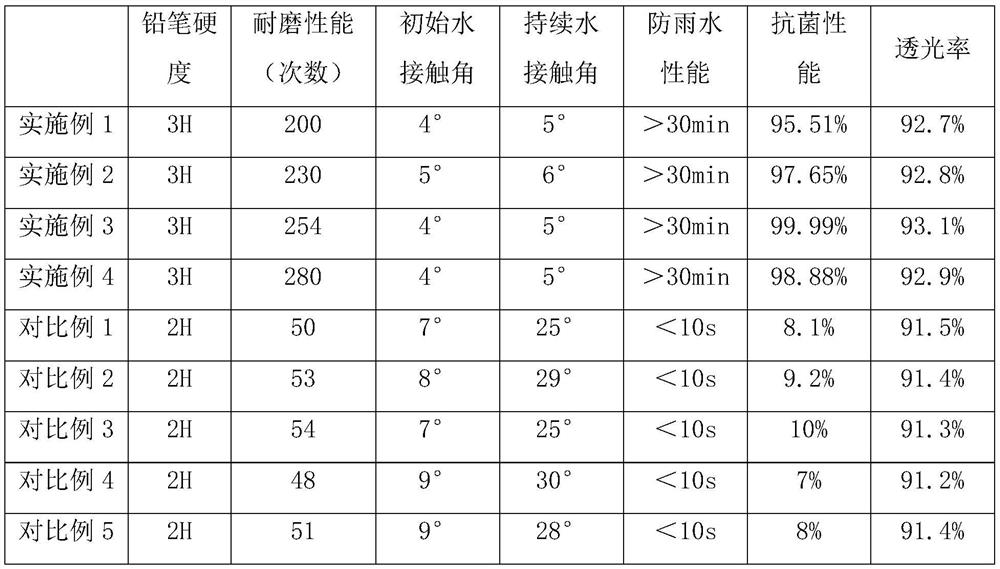

Examples

Embodiment 1-4

[0025] Components of Table 1 Embodiment 1-4 and parts by weight thereof

[0026]

[0027] The ZXL-CFW (product code) used in Examples 1-4 is an aqueous dispersion formed by dispersing hydroxyl-modified nano-silica in water. The ZXL-CQS (product code) used in Examples 1-4 is an aqueous dispersion formed by dispersing amino-modified nano-titanium dioxide in water. The solid content of the super-hydrophilic nano-silica water dispersion and the super-hydrophilic nano-titanium dioxide water dispersion are both 10%-12%.

[0028] The preparation process of the anti-fog film: weigh the water-based UV-curable resin, water-based heat-curable resin, super-hydrophilic nano-silica aqueous dispersion, super-hydrophilic nano-titanium dioxide aqueous dispersion according to the components in Table 1 and their parts by weight. Liquid, water-based additives, water-based leveling agent, cross-linking agent and photoinitiator are added to a stirrer and stirred at high speed for 30-50 minutes,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com