A polymer drag reducer for oil and gas development and its preparation process

A preparation process and polymer technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems affecting the drag reduction rate of drag reducers, achieve good thermodynamic properties, improve stability, and increase the degree of hydrophobic association Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

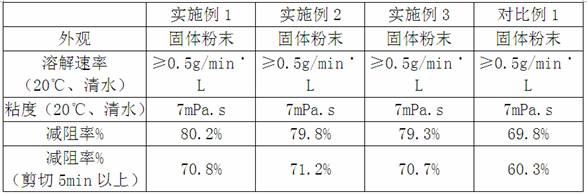

Examples

Embodiment 1

[0041] A polymer drag reducer for oil and gas development, consisting of drag reducing components, film-forming components and microcrystalline wax;

[0042] The polymer drag reducer used for oil and gas development is prepared through the following steps:

[0043] The first step is to prepare the drag reducing component;

[0044] The second step, preparing the film-forming component;

[0045] The third step is to weigh the drag-reducing component and the film-forming component according to the mass ratio of 3:2, set the temperature at 100°C, heat the film-forming component and the drag-reducing component to melt, stir and mix for 50min, and then set the temperature at 60±2°C Dry to constant weight to obtain the first component, then heat the microcrystalline wax at 95±2°C until it is completely dissolved, immerse the first component in the dissolved microcrystalline wax for 10±2s, take it out, and then quickly add it to deionized water Rapidly solidify and dry to obtain a p...

Embodiment 2

[0059] A polymer drag reducer for oil and gas development, consisting of drag reducing components, film-forming components and microcrystalline wax;

[0060] The polymer drag reducer used for oil and gas development is prepared through the following steps:

[0061] The first step is to prepare the drag reducing component;

[0062] The second step, preparing the film-forming component;

[0063] The third step is to weigh the drag-reducing component and the film-forming component according to the mass ratio of 3:2, set the temperature at 120°C, heat the film-forming component and the drag-reducing component to melt, stir and mix for 55min, and then set the temperature at 60±2°C Dry to constant weight to obtain the first component, then heat the microcrystalline wax at 95±2°C until it is completely dissolved, immerse the first component in the dissolved microcrystalline wax for 10±2s, take it out, and then quickly add it to deionized water Rapidly solidify and dry to obtain a p...

Embodiment 3

[0077] A polymer drag reducer for oil and gas development, consisting of drag reducing components, film-forming components and microcrystalline wax;

[0078] The polymer drag reducer used for oil and gas development is prepared through the following steps:

[0079] The first step is to prepare the drag reducing component;

[0080] The second step, preparing the film-forming component;

[0081] The third step is to weigh the drag-reducing component and the film-forming component according to the mass ratio of 4:2, set the temperature at 140°C, heat the film-forming component and the drag-reducing component to melt, stir and mix for 60min, and then heat the mixture at 60±2°C Dry to constant weight to obtain the first component, then heat the microcrystalline wax at 95±2°C until it is completely dissolved, immerse the first component in the dissolved microcrystalline wax for 10±2s, take it out, and then quickly add it to deionized water Quickly solidify and dry to obtain a poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com