Impurity removal method of copper sulfate solution

A copper sulfate solution and solution technology, applied in the direction of improving process efficiency, etc., can solve the problems of limited application scope, complicated impurity removal process, low zinc and iron removal efficiency, etc., and achieve the effect of overcoming treatment difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

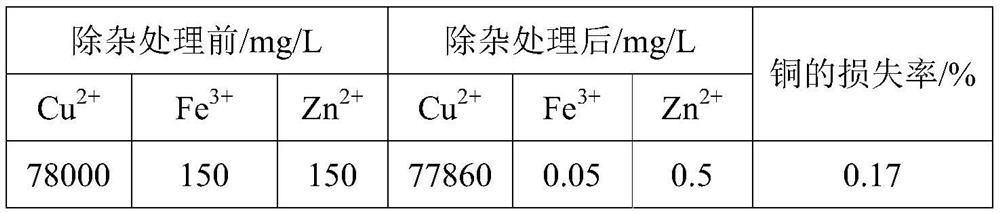

Embodiment 1

[0038] A method for removing impurities of copper sulfate solution, comprising the steps of:

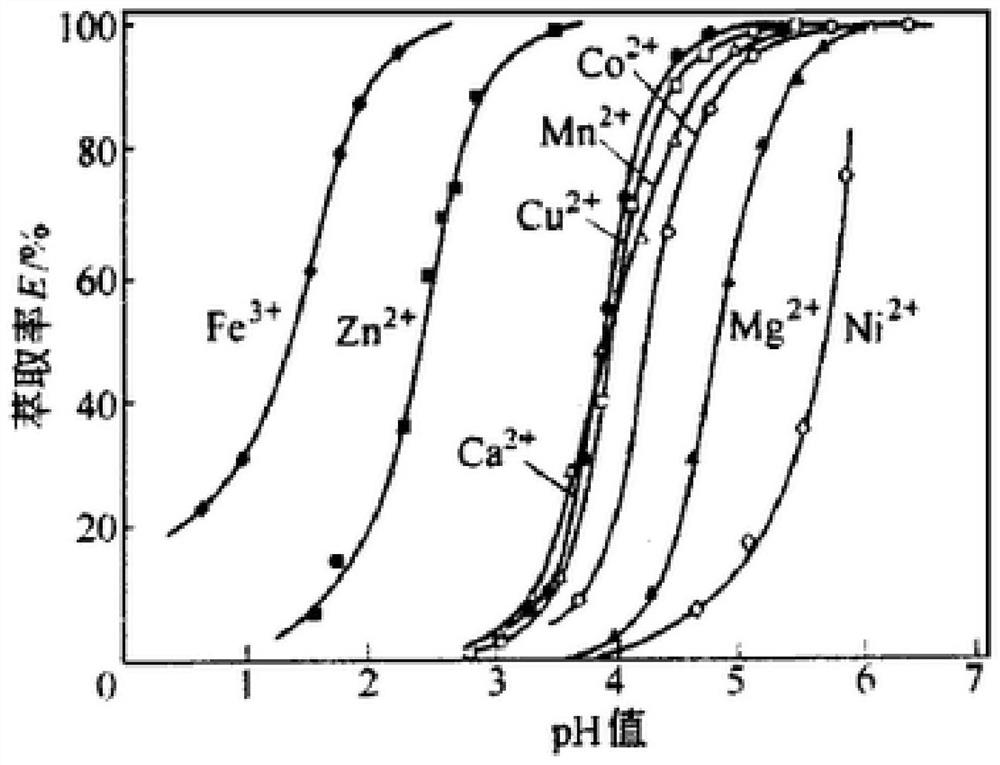

[0039] S1. pH adjustment of the copper sulfate solution: adjust the pH value of the copper sulfate solution to 2.4 with 98% concentrated sulfuric acid;

[0040] S2. Removal of iron and zinc by resin: The above-mentioned copper sulfate solution adjusted to pH in S1 flows forward through the P507 extraction resin column at a flow rate of 1 BV / h to obtain a copper sulfate solution for removing impurities.

[0041] Among them, the P507 extraction resin column is regenerated by the following method:

[0042] S3. Pickling: use H-containing P507 resin saturated with iron and zinc ions + The dilute hydrochloric acid solution with a concentration of 6mol / L is washed forward, the flow rate of the dilute hydrochloric acid solution in the resin column is 1BV / h, and the water is washed until the effluent is colorless;

[0043] S4. Washing with water: wash the above acid-washed P507 resin until th...

Embodiment 2

[0048] A method for removing impurities of copper sulfate solution, comprising the steps of:

[0049] S1. pH value adjustment of copper sulfate solution: adjust the pH value of copper sulfate solution to 2.9 with 50% sulfuric acid solution;

[0050] S2. Removal of iron and zinc by resin: the copper sulfate solution adjusted in pH above S1 was flowed forward through the P507 extraction resin column at a flow rate of 30BV / h to obtain a copper sulfate solution for removing impurities.

[0051] Among them, the P507 extraction resin column is regenerated by the following method:

[0052] S3. Pickling: use H-containing P507 resin saturated with iron and zinc ions + The dilute sulfuric acid solution with a concentration of 1mol / L is washed forward, the flow rate of the dilute sulfuric acid solution in the resin column is 20BV / h, and the water is washed until the effluent is colorless;

[0053] S4. Washing with water: washing the above acid-washed P507 resin until the pH value of th...

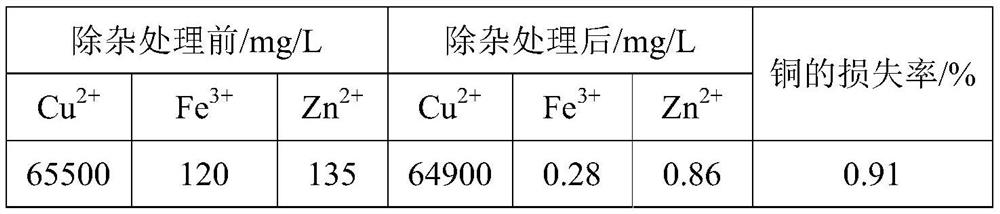

Embodiment 3

[0058] A method for removing impurities of copper sulfate solution, comprising the steps of:

[0059] S1. pH adjustment of the copper sulfate solution: adjust the pH value of the copper sulfate solution to 2.6 with 98% concentrated sulfuric acid;

[0060] S2. Removal of iron and zinc by resin: the above-mentioned S1 copper sulfate solution adjusted to pH is flowed forward through the P507 extraction resin column at a flow rate of 15BV / h to obtain a copper sulfate solution for removing impurities.

[0061] Among them, the P507 extraction resin column is regenerated by the following method:

[0062] S3. Pickling: use H-containing P507 resin saturated with iron and zinc ions + The dilute hydrochloric acid solution with a concentration of 3mol / L is washed forward, the flow rate of the dilute hydrochloric acid solution in the resin column is 10BV / h, and the water is washed until the effluent is colorless;

[0063] S4. Washing with water: wash the above acid-washed P507 resin unti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com