Molten resin defoaming method and spinning forming method

A technology of molten resin and forming method, which is applied in the direction of melt spinning, filament forming treatment, spinning solution filtration, etc., which can solve the problems of sticking and agglomeration of molten resin on scrapers or umbrella pages, so as to reduce air bubbles and avoid Effect of degradation reaction and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a method for defoaming molten resin, comprising the steps of:

[0042] S1, feed;

[0043] S2. Spinning the molten resin in a vacuum environment;

[0044] S3. In a vacuum environment, degassing the spun resin.

[0045] Further, vacuum treatment is carried out after feeding. The molten resin is then subjected to a spinning process. Since the molten resin is in a vacuum room temperature environment after the spinning process, the molten resin is sprayed out into resin filaments due to the lowering of the resin temperature and the high viscosity of the resin. The resin filaments are always in a vacuum environment, and the specific surface area of the resin sprayed into a filament state increases significantly, and air bubbles exist on the surface or inside of the resin filaments. The surface or inside of the silk escapes, and the vacuum defoaming effect is remarkable.

[0046] In the step S1, the feeding process is carried out in a vacuum envi...

Embodiment 2

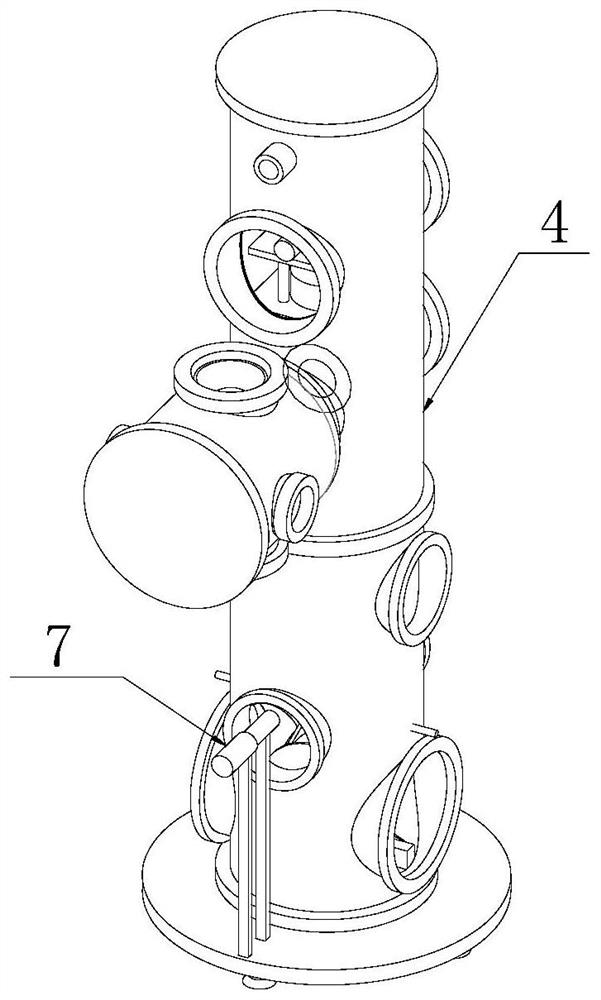

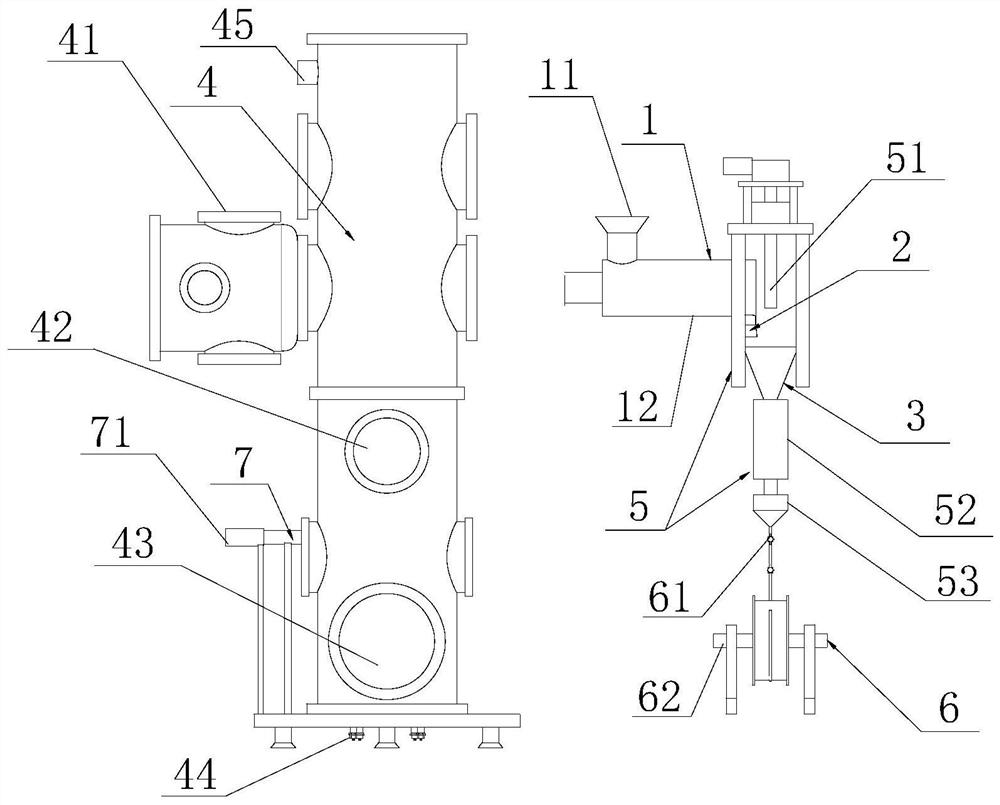

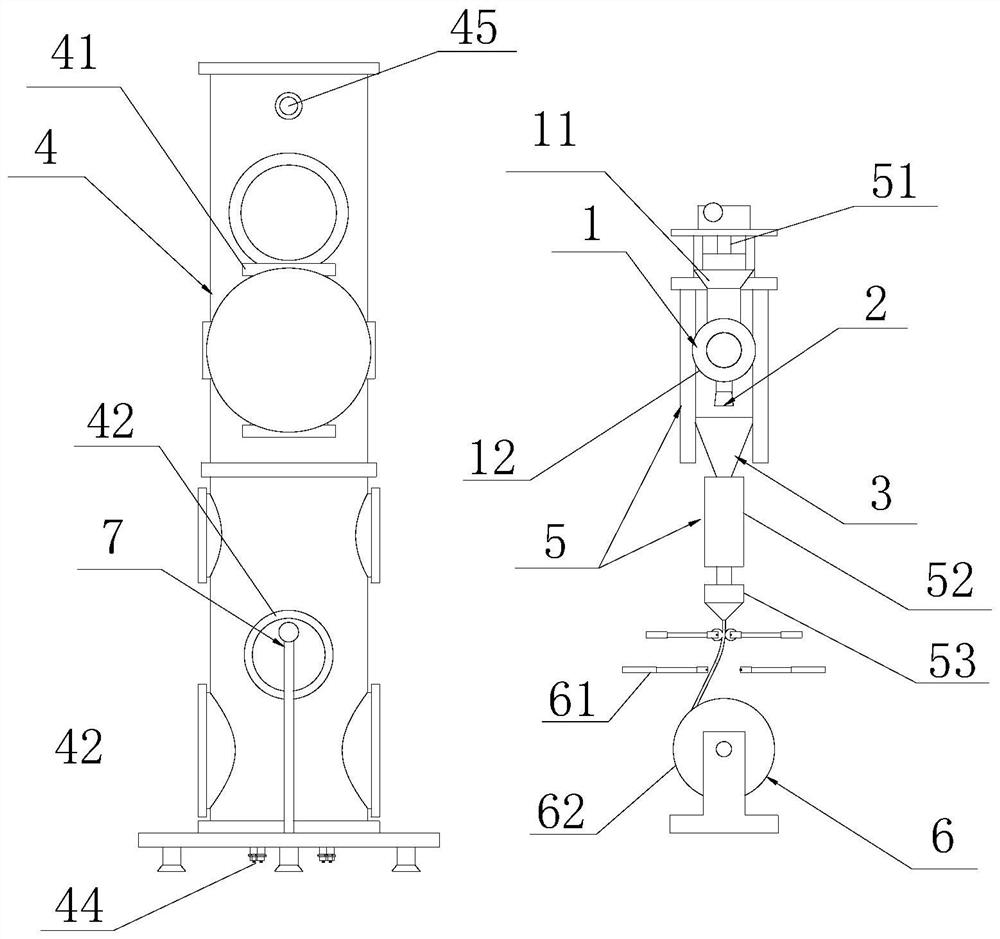

[0053] Such as Figure 1 to Figure 3 As shown, the present embodiment provides a degassing device, the degassing device includes a feed module 1, and a spinning module 2 connected to the feed module 1; a degassing module 3, used for resin degassing, The degassing module 3 is arranged under the spinning module 2 ; the vacuum chamber 4 , the spinning module 2 and the degassing module 3 are arranged in the vacuum chamber 4 . The vacuum chamber 4 in this embodiment is connected to a vacuum pump (not shown in the figure) through the vacuum port 45 to extract the air in the vacuum chamber 4 to create a vacuum environment.

[0054] Further, the feeding module 1 is arranged outside the vacuum chamber 4, the feeding module 1 is connected to the spinning module 2, and after the molten resin is fed, the first extruder 12 and the The molten resin forms a closed space, and the vacuum pump is turned on to evacuate, so that the spinning module 2 and the degassing module 3 can obtain a vacuu...

Embodiment 3

[0064] Such as Figure 1 to Figure 6 As shown, this embodiment provides a spinning forming device, the spinning forming device includes the degassing device described in Embodiment 2, and also includes a spinning module 5 for degassing the defoaming device Resin spinning molding.

[0065] Further, the spinning module 5 includes a heating cylinder 52, which is arranged under the defoaming module 3, and one end of the heating cylinder 52 is connected with the defoaming module 3; the second extruder 51 is arranged on the above the degassing module 3, cooperate with the hollow chamber of the degassing module 3, and reciprocate in the heating cylinder 52 along the axial direction of the second extruder 51; the second spinneret 53, The second spinneret 53 is connected to the other end of the heating cylinder 52 . The present invention also connects one end of the heating cylinder 52 to the degassing module 3, so that the resin degassed by the degassing device can directly enter th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com