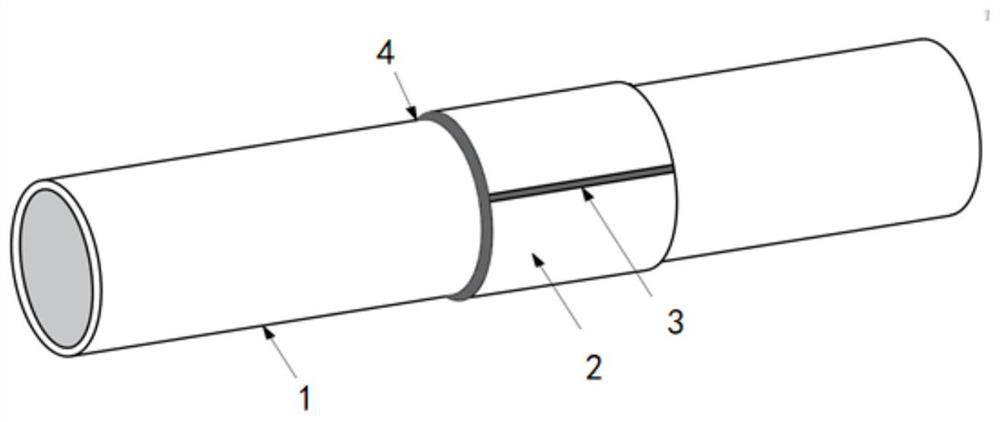

Method for calculating thickness of B-type sleeve for repairing circumferential weld crack defects of oil and gas pipeline

A technology for oil and gas pipelines and defect repair, applied in the directions of calculation, computer-aided design, design optimization/simulation, etc., can solve the problems of difficult to guarantee welding quality, easy to produce welding defects, large welding workload, etc. The effect of reducing the probability of welding defects and ensuring the safety of pipeline service

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

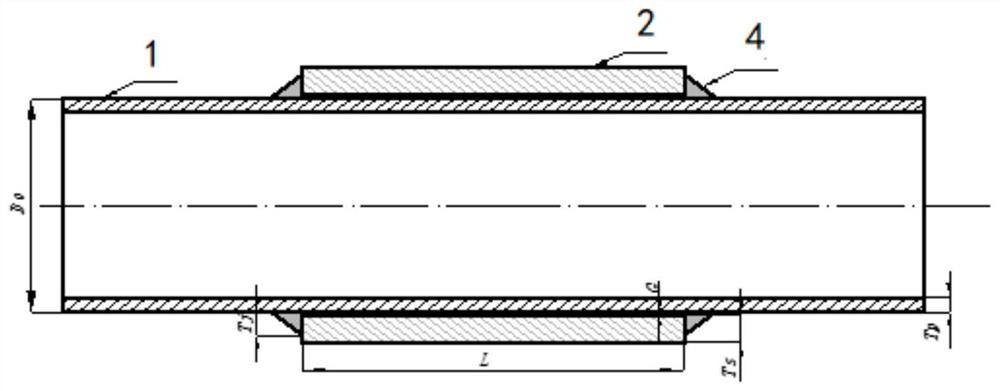

[0070] Taking the second line of the West-East Gas Pipeline Pipeline as an example, the specification is D1219×18.4mm, X80 steel grade pipeline girth weld crack defect repair, the design pressure of the pipeline is 10MPa, and the most widely used Q345R material B-type sleeve is used for repair.

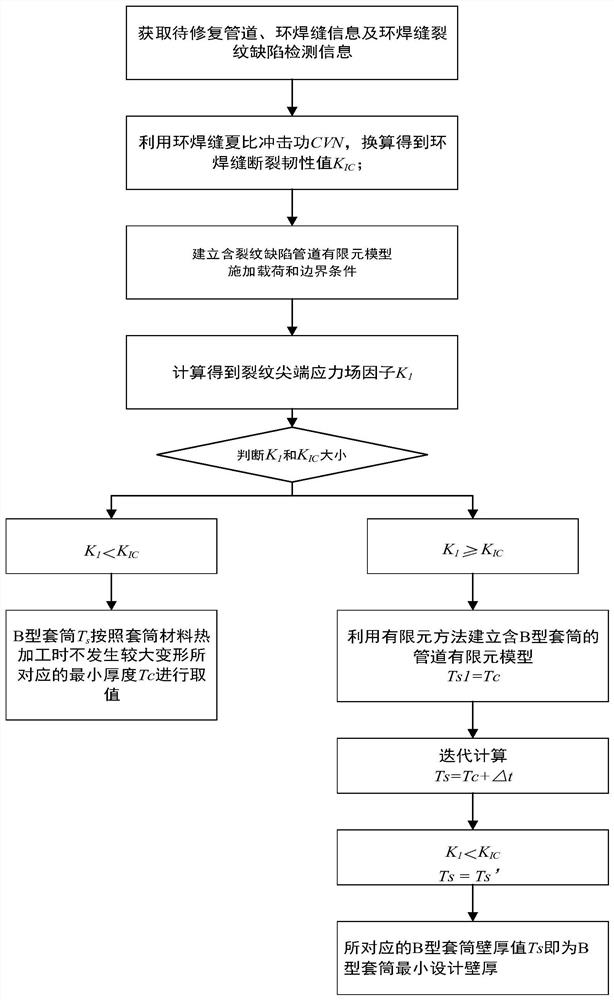

[0071] Calculation method of the present invention, the steps are as follows:

[0072] (1) Obtain the pipeline to be repaired, girth weld information and girth weld crack defect detection information;

[0073] Outer diameter of the pipe to be repaired D O 1219mm, wall thickness T p It is 18.4mm, the pipe material is X80, and the material density is 7.8g / cm 3 , elastic modulus 210000MPa, Poisson's ratio 0.3, yield strength σ s 555MPa, tensile strength σ b is 625MPa, elongation is 0.2, Charpy impact energy CVN is 60J; the girth weld is equal to the pipeline; the girth weld defect is a circumferential crack on the inner surface, and the crack depth a is 9.2mm (T p / 2), the length 2c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com