Making method of additive-free crisp cheese

A production method and an additive-free technology, applied in the field of pastry processing, can solve problems such as unfavorable large-scale or long-term consumption, consumer health impact, etc., and achieve the effects of convenient carrying and storage, round and compact shape, and convenient storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

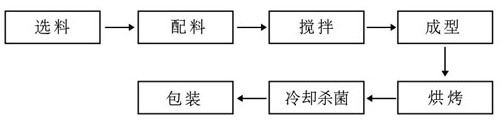

[0024] A method for making cheese brittle without additives, comprising the following steps:

[0025] (1) Material selection: Choose products with complete packaging, complete certificates, and products that meet the requirements of corresponding product standards during the shelf life. The raw materials are edible starch, glutinous rice flour, fresh eggs, drinking water, Anjia butter, white sugar, milk powder, cheese, edible Salt; the raw materials do not contain preservatives, antioxidants, anti-aging agents and other additives, and do not contain pigments and essences; according to actual needs, natural fruit and vegetable powders (purple sweet potato powder, strawberry powder, spinach powder, carrot powder, etc.) The product has a natural fruit and vegetable color;

[0026] (2) Ingredients: select raw materials according to the proportion, edible s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com