A welding and fixing method for a welded joint of an automobile front stabilizer beam

A fixing method and welding technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of large deviation of parts manufacturing accuracy, occupying storage space, and large degree of differentiation, reducing labor intensity and improving efficiency. , good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings, but this embodiment should not be construed as limiting the present invention.

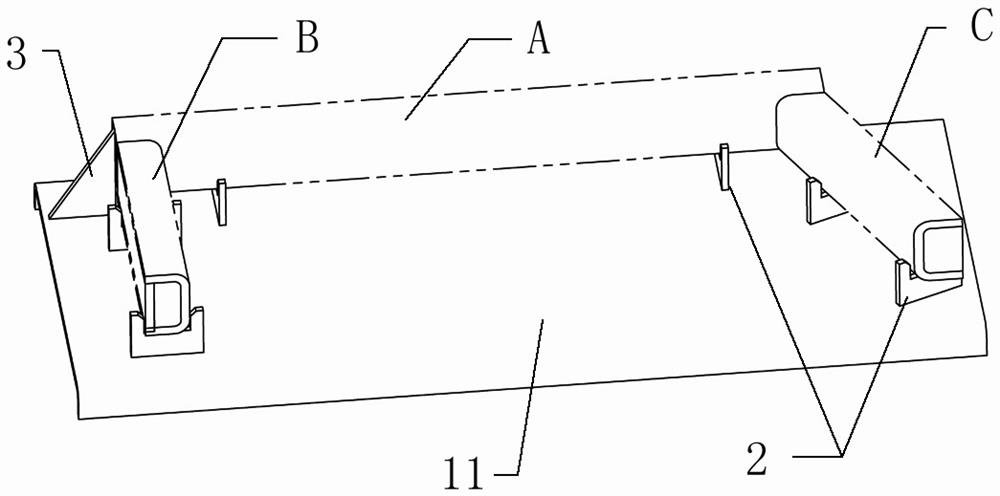

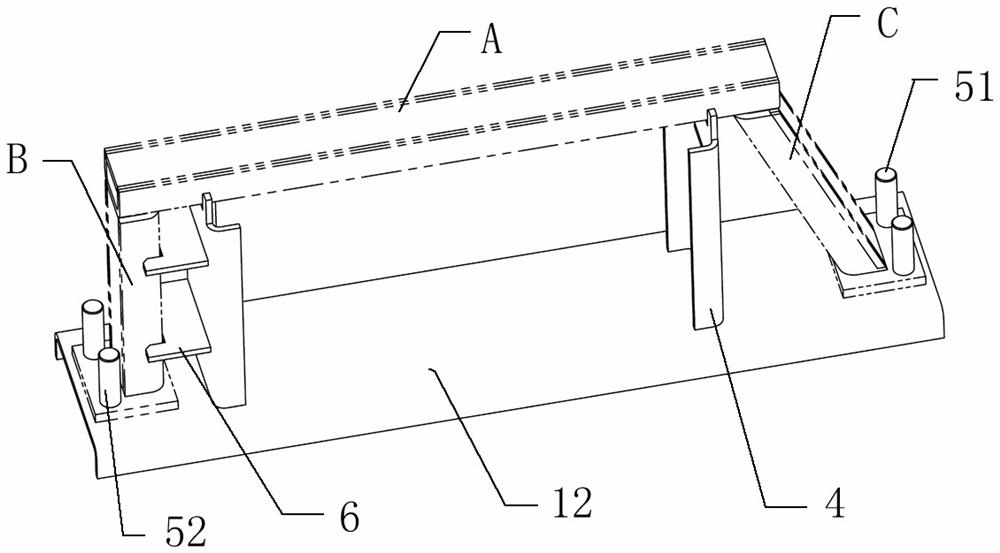

[0028] A method for welding and fixing a welded joint of a front stabilized beam of an automobile, the welded joint of the front stabilized beam of an automobile comprises a crossbeam A, a vertical beam B is welded and fixed on the bottom of one end of the crossbeam, and a vertical beam B is welded and fixed on the bottom of the other end of the crossbeam to be inclined outwards. For inclined beam C, the centerlines of the beam, vertical beam, and inclined beam lie in the same plane:

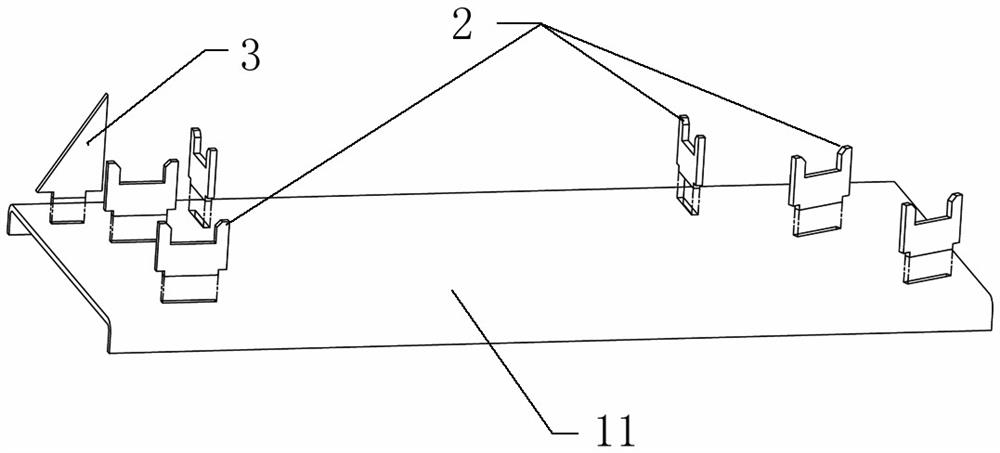

[0029] (1) In order to weld the welded parts of the automobile front stabilizer beam, a special fixture that can be spliced quickly is adopted, and the structure of the special fixture ( Figure 1 to Figure 4 shown) is: including horizontal splicing fixtures and verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com