A fixing device for metal welding

A fixing device and metal welding technology, which is applied in the direction of welding equipment, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of poor fixing effect of metal pipes, affect welding quality, and generate vibration, so as to achieve accurate fixing, save fixing time, The effect of lowering operating restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

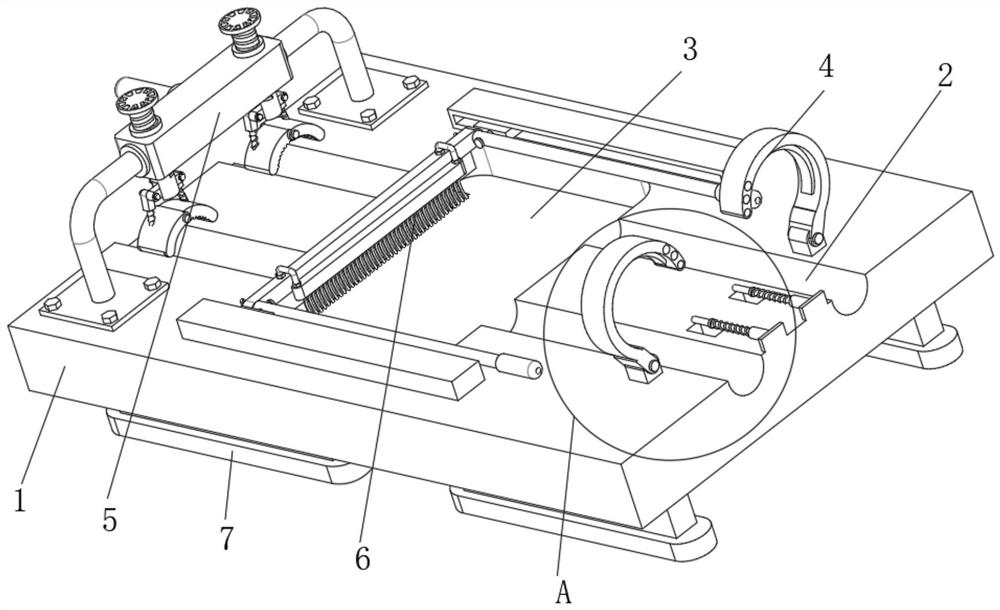

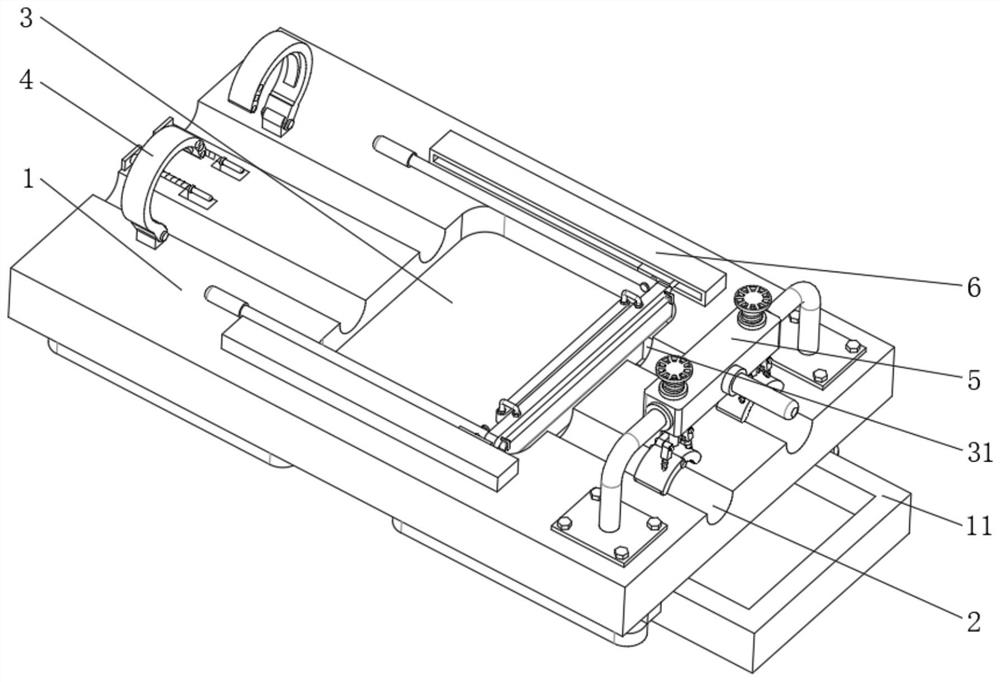

[0032] Example 1, as Figure 1-7 As shown, the present invention provides a fixing device for metal welding, comprising a workbench 1, a limit slot 2 is provided at both ends of the top of the workbench 1, and a top of the workbench 1 is located between the two limit slots 2. In the miscellaneous storage tank 3, the top of the worktable 1 is located at one end of the two limit grooves 2, and a rust removal assembly 4 is fixedly installed. The top of the workbench 1 is located on both sides of the miscellaneous storage tank 3 and a cleaning component 6 is provided on the top.

[0033] The specific settings and functions of the fastening device 5 will be described in detail below.

[0034] like figure 2 and image 3 As shown, the fastening device 5 includes a support shaft 51, two ends of the support shaft 51 are fixedly installed on one side of the two limiting grooves 2 respectively, the outer surface of the support shaft 51 is rotatably connected with a turning block 52, ...

Embodiment 2

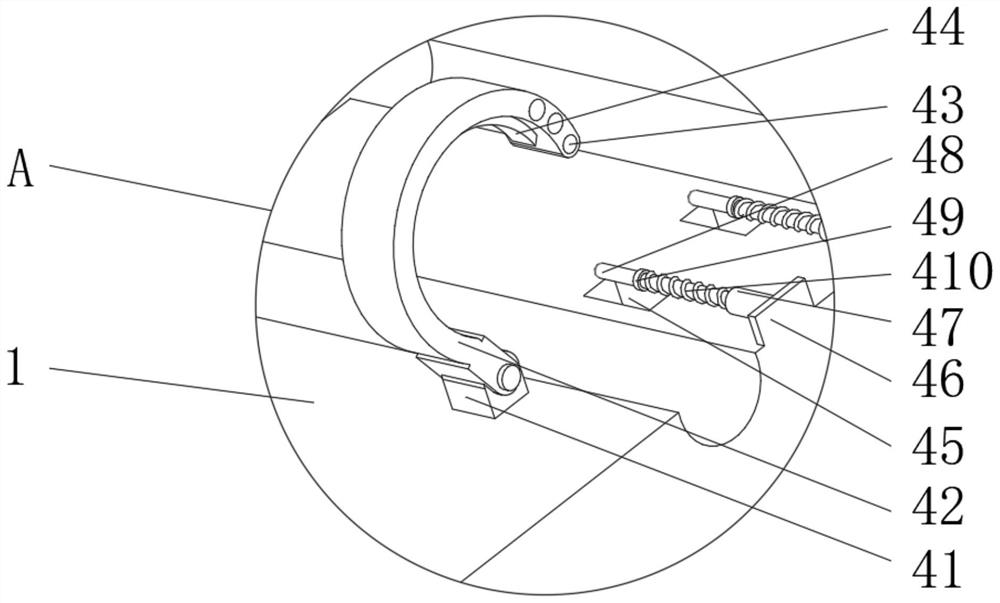

[0037] The specific settings and functions of the rust removal component 4 will be described in detail below.

[0038] like figure 2 and Figure 4 As shown, the rust removal assembly 4 includes a connector 41 and a slot 45. The connector 41 and the slot 45 are respectively arranged on both sides of the single limit slot 2 at the top of the workbench 1. The top of the connector 41 is hinged with a half hoop 42. A scraper 44 is fixedly installed on the opposite side of the half hoop 42 and the limit groove 2, a bump 46 is fixedly installed on the top of the worktable 1 at the edge, and a sleeve 47 is fixedly installed on the side wall of the outer surface of the bump 46. The inner wall of the tube 47 is slidably connected with a positioning pin 48, a limit ring 49 is provided on the outer surface of the positioning pin 48, and an elastic spring 410 is sleeved at one end of the positioning pin 48 between the limit ring 49 and the sleeve 47. The two ends are respectively fixedl...

Embodiment 3

[0041] The specific settings and functions of the cleaning component 6 will be described in detail below.

[0042] The cleaning assembly 6 includes a bar-shaped block 61. The top of the workbench 1 is located on both sides of the miscellaneous storage tank 3. The bar-shaped block 61 is fixedly installed. The inner wall of 62 is slidably connected with a slider 63, the opposite sides of the two sliders 63 are fixedly installed with a shaft 64, the outer surface of the shaft 64 is rotatably connected with a connecting rod 65, and the two connecting rods 65 are away from one end of the shaft 64 A connecting block 66 is fixedly installed, and a cleaning knife 67 and a brush 68 are fixedly installed on both sides of the outer surface of the connecting block 66. A return spring 69 is fixedly installed between the sliding block 63 and the opposite side of the chute 62. The interior of 3 is provided with a miscellaneous outlet 31, and the bottom of the workbench 1 is fixedly installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com