Method for preparing acetaldoxime by adopting continuous method

A technology of acetaldehyde oxime and acetaldehyde, which can be used in oxime preparation, organic chemistry and other directions, and can solve problems such as discontinuous reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

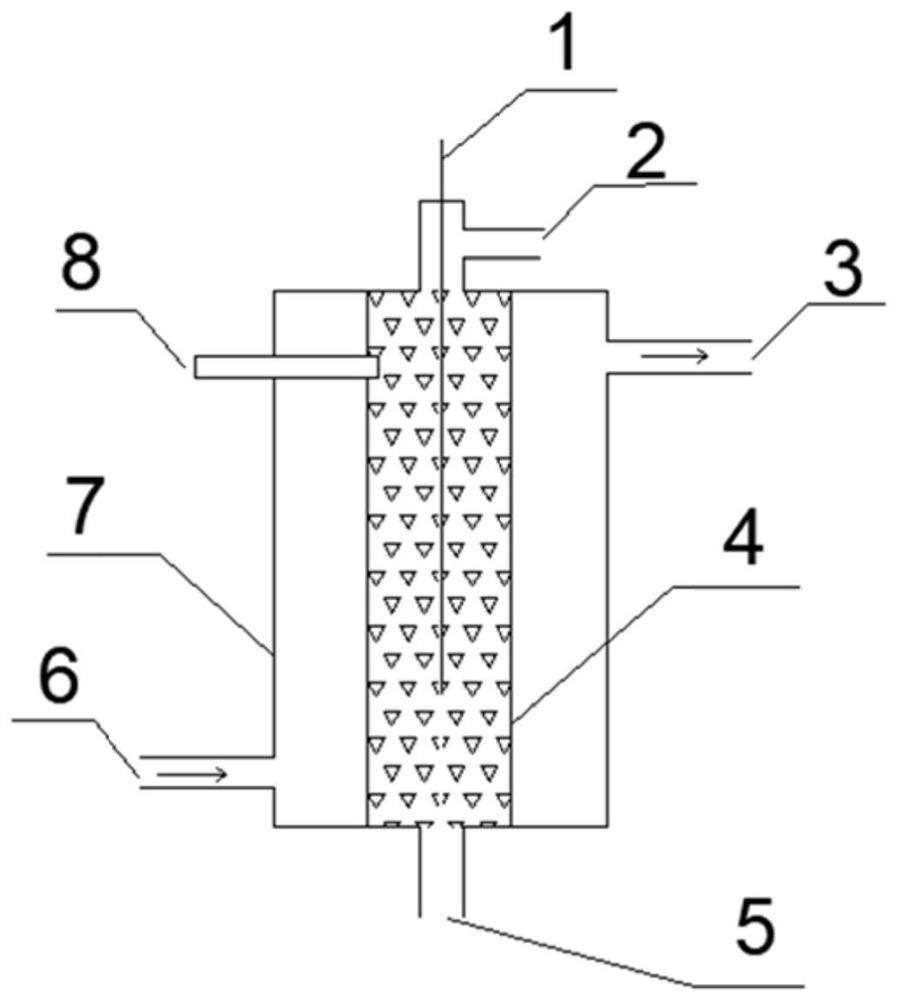

Method used

Image

Examples

Embodiment 1

[0024]First configure the mass concentration of 50% hydroxylamine hydrochloride aqueous solution, 40% acetaldehyde aqueous solution, 20% ammonia water, and fill 20-40 mesh quartz sand in the jacketed reactor; connect the jacketed reactor to the refrigerator, and set the refrigeration temperature -5℃; The molar ratio of hydroxylamine hydrochloride aqueous solution, acetaldehyde, and ammonia water is 1:1.05:1.1; under normal pressure, use a metering pump to separate hydroxylamine hydrochloride aqueous solution 2.32g / min, acetaldehyde aqueous solution 1.93g / min, and ammonia 1.56 g / min was fed into the reactor at the same time; running for 20 minutes, reaction temperature 15.4°C, reaction pressure 0.01MPa, pH=7.1, outlet GC detection, hydroxylamine hydrochloride conversion rate ≥99.7%, acetaldoxime selectivity ≥99.4%.

Embodiment 2

[0026]First configure the mass concentration of 50% hydroxylamine hydrochloride aqueous solution, 40% acetaldehyde aqueous solution, 20% ammonia water, and fill 20-40 mesh quartz sand in the jacketed reactor; connect the jacketed reactor to the refrigerator, and set the refrigeration temperature -5℃; The molar ratio of hydroxylamine hydrochloride aqueous solution, acetaldehyde and ammonia water is 1:1.05:1.1; under normal pressure, the hydroxylamine hydrochloride aqueous solution 4.18g / min, the acetaldehyde aqueous solution 3.47g / min and ammonia 2.81 g / min was fed into the reactor at the same time; running for 20 minutes, the reaction temperature was 24.6°C, the reaction pressure was 0.01MPa, pH=7.2, and the outlet GC test showed that the conversion of hydroxylamine hydrochloride was ≥99.4%, and the selectivity of acetaldoxime was ≥99.3%.

Embodiment 3

[0028]First configure the mass concentration of 50% hydroxylamine hydrochloride aqueous solution, 40% acetaldehyde aqueous solution, 20% ammonia water, and fill 20-40 mesh quartz sand in the jacketed reactor; connect the jacketed reactor to the refrigerator, and set the refrigeration temperature -5℃; The molar ratio of the three materials of hydroxylamine hydrochloride aqueous solution, acetaldehyde and ammonia water is 1:1.05:1.1; under normal pressure, the hydroxylamine hydrochloride aqueous solution is 3.48g / min, the acetaldehyde aqueous solution 2.9g / min, and the ammonia water are 2.34 by the metering pump. g / min was fed into the reactor at the same time; running for 20 minutes, the reaction temperature was 20.4°C, the reaction pressure was 0.01MPa, pH=7.1, and the outlet GC test showed that the conversion rate of hydroxylamine hydrochloride was ≥99.6%, and the selectivity of acetaldoxime was ≥99.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com