Cryogenic treatment method of graphene reinforced Ti2AlNb composite material

A technology for cryogenic treatment and composite materials, which is applied in the field of cryogenic treatment of graphene-reinforced Ti2AlNb composite materials, can solve problems such as affecting the bonding performance of composite interfaces, reducing the comprehensive performance of composite materials, and large residual stress of composite materials, so as to improve the bonding performance of the interface. , Improve the comprehensive mechanical properties and reduce the effect of residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

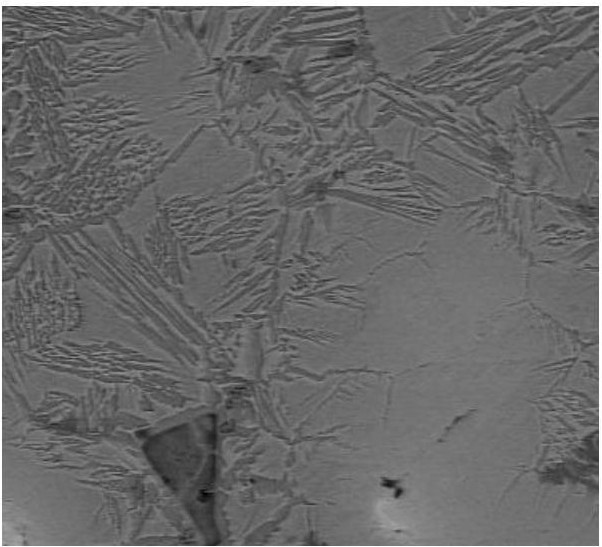

Image

Examples

Embodiment 1

[0017] A graphene-enhanced Ti 2 The cryogenic treatment method of AlNb composite material,

[0018] Step 1. Graphene Reinforced Ti 2 Put the AlNb composite material sample into the cryogenic treatment device, and seal the device;

[0019] Step 2. Fill liquid nitrogen into the airtight cryogenic treatment device to lower the internal temperature from room temperature to minus 130°C at a cooling rate of 10°C / min, keep the temperature for 5 hours, and then drop to minus 196°C at a cooling rate of 20°C / min. ℃, holding time is 20 hours;

[0020] Step 3. Raise the temperature of the sample in the cryogenic treatment device to room temperature at a heating rate of 5°C / min;

[0021] Step 4. Repeat the cryogenic treatment for 4 times as described in step 2 and step 3 with the cryogenically treated sample obtained in step 3 and then take out the sample.

Embodiment 2

[0023] A graphene-enhanced Ti 2 The cryogenic treatment method of AlNb composite material,

[0024] Step 1. Graphene Reinforced Ti 2 Put the AlNb composite material sample into the cryogenic treatment device, and seal the device;

[0025] Step 2. Fill liquid nitrogen into the airtight cryogenic treatment device, make its internal temperature drop from room temperature to minus 100°C at a cooling rate of 1°C / min, keep it warm for 1 hour, and then drop to minus 130°C at a cooling rate of 1°C / min ℃, holding time is 20 hours;

[0026] Step 3. Raise the temperature of the sample in the cryogenic treatment device to room temperature at a heating rate of 1°C / min;

[0027] Step 4. Repeat the cryogenic treatment for 4 times as described in step 2 and step 3 with the cryogenically treated sample obtained in step 3 and then take out the sample.

Embodiment 3

[0029] A graphene-enhanced Ti 2 The cryogenic treatment method of AlNb composite material,

[0030] Step 1. Graphene Reinforced Ti 2 Put the AlNb composite material sample into the cryogenic treatment device, and seal the device;

[0031] Step 2. Fill liquid nitrogen into the airtight cryogenic treatment device, make its internal temperature drop from room temperature to minus 130°C at a cooling rate of 30°C / min, keep it warm for 5 hours, and then drop to minus 150°C at a cooling rate of 30°C / min ℃, holding time is 20 hours;

[0032] Step 3. Raise the temperature of the sample in the cryogenic treatment device to room temperature at a heating rate of 20°C / min;

[0033] Step 4. Repeat the cryogenic treatment for 4 times as described in step 2 and step 3 with the cryogenically treated sample obtained in step 3 and then take out the sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com