A pulsed magnetic field generator and its working method

A pulsed magnetic field and working method technology, applied in the direction of magnets, electromagnets, magnetic objects, etc., can solve the problems of performance deterioration, time-consuming and energy-consuming, changing the structure of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below with reference to the accompanying drawings.

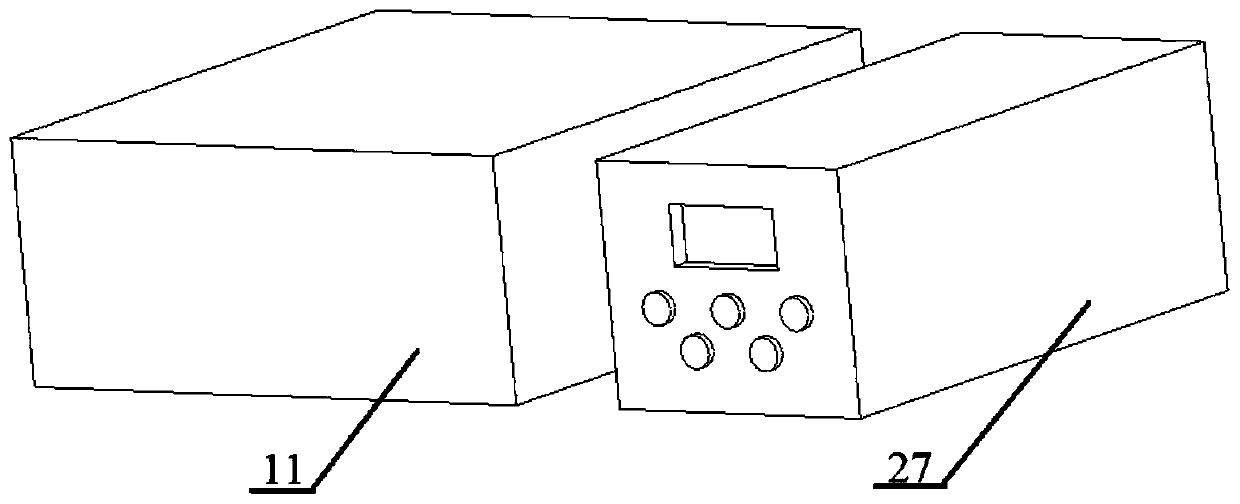

[0036] like Figure 1 to Figure 4 As shown, a pulsed magnetic field generator includes a control box 27 and a magnetizing coil 11;

[0037] The control box 27 includes a pulse discharge control board 26, a single-phase fully isolated rectification and voltage regulation module 3, operation buttons and a display screen 21;

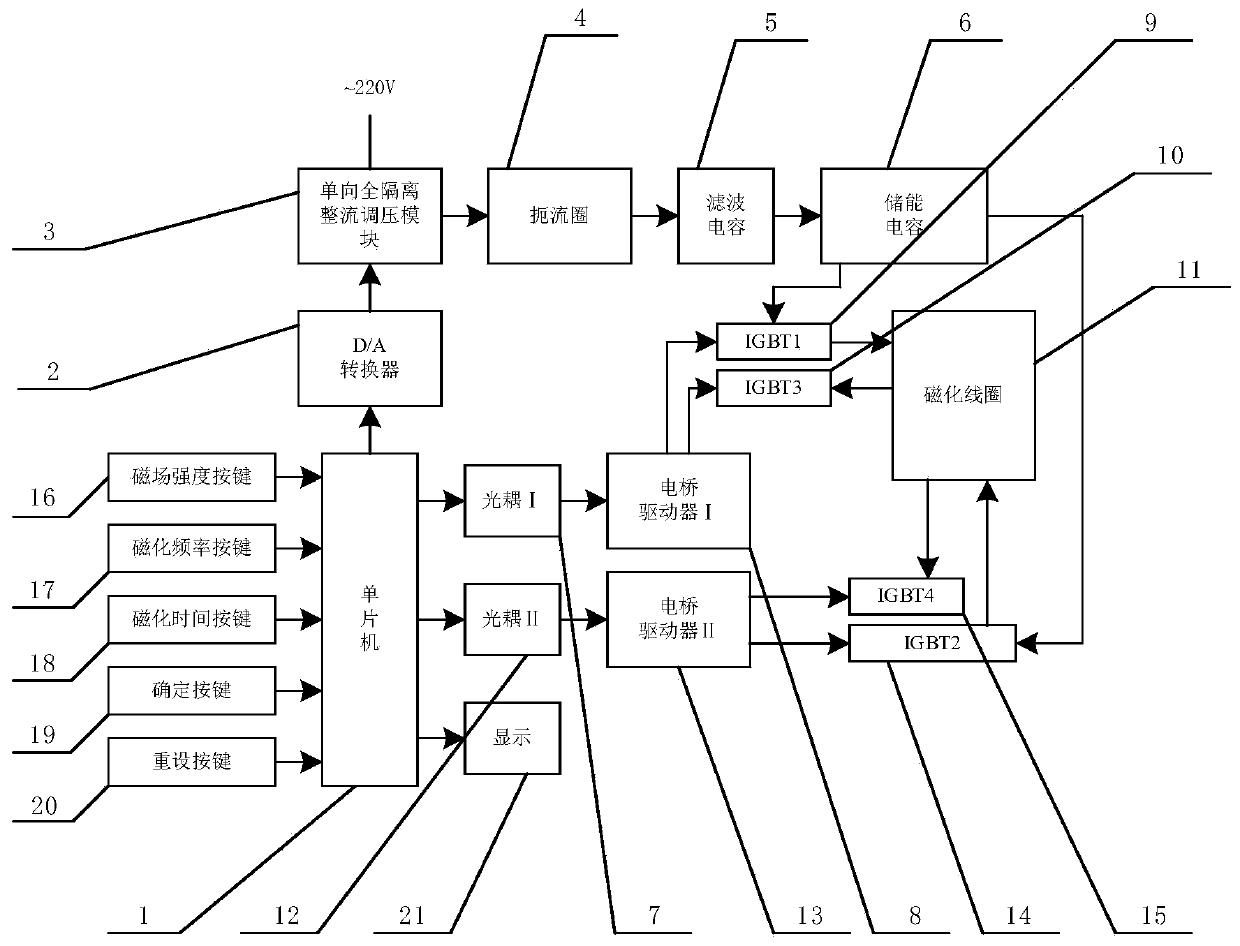

[0038] The pulse discharge control board 26 includes: single chip microcomputer 1, D / A converter 2, choke coil 4, filter capacitor 5, energy storage capacitor 6, optocoupler I7, bridge driver I8, IGBT1 9, IGBT3 10, optocoupler II12, bridge driver II13, IGBT2 14 and IGBT4 15;

[0039] The operation buttons include: a magnetic field strength button 16 , a magnetization frequency button 17 , a magnetization time button 18 , a confirmation button 19 and a reset button 20 .

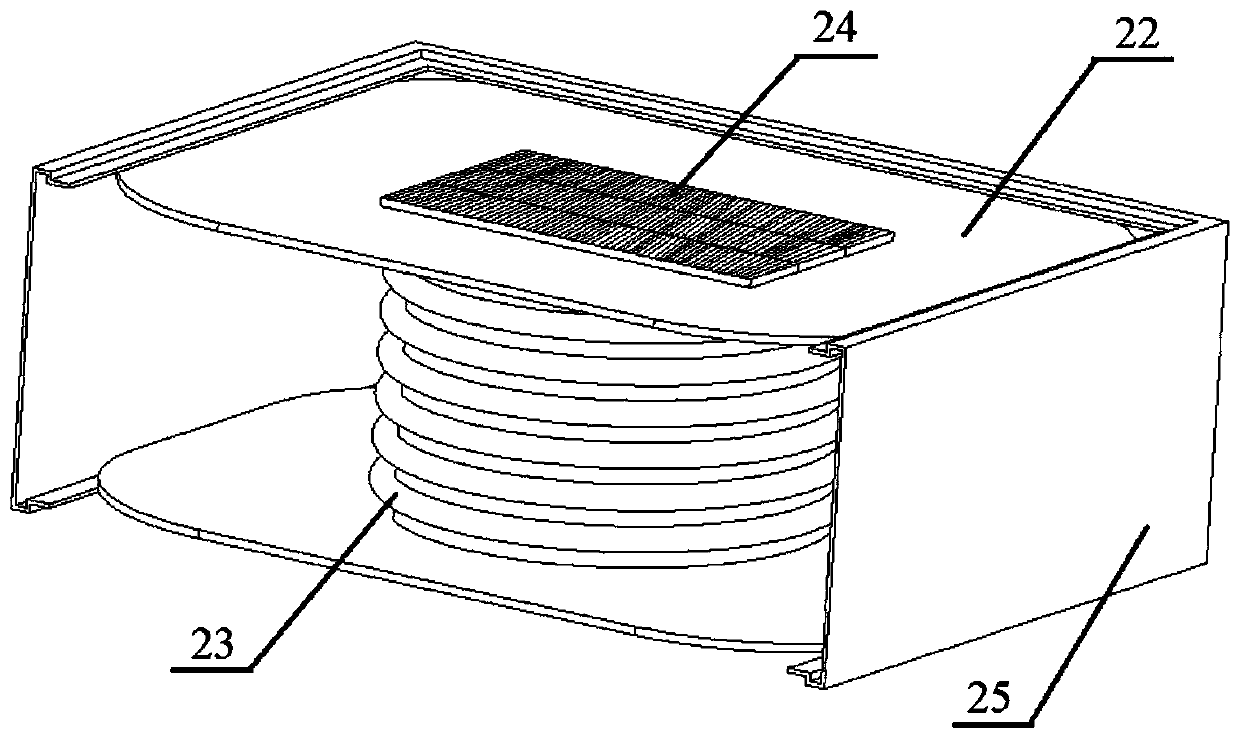

[0040] On the basis of the above scheme, the magnetizing coil 11 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com