Multi-flow-channel gas ejector with tandem cooling chambers

A gas injector and cooling chamber technology, applied in the field of multi-channel gas injectors, can solve the problems of poor temperature control effect, easy dust accumulation, and easy accumulation of reactants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

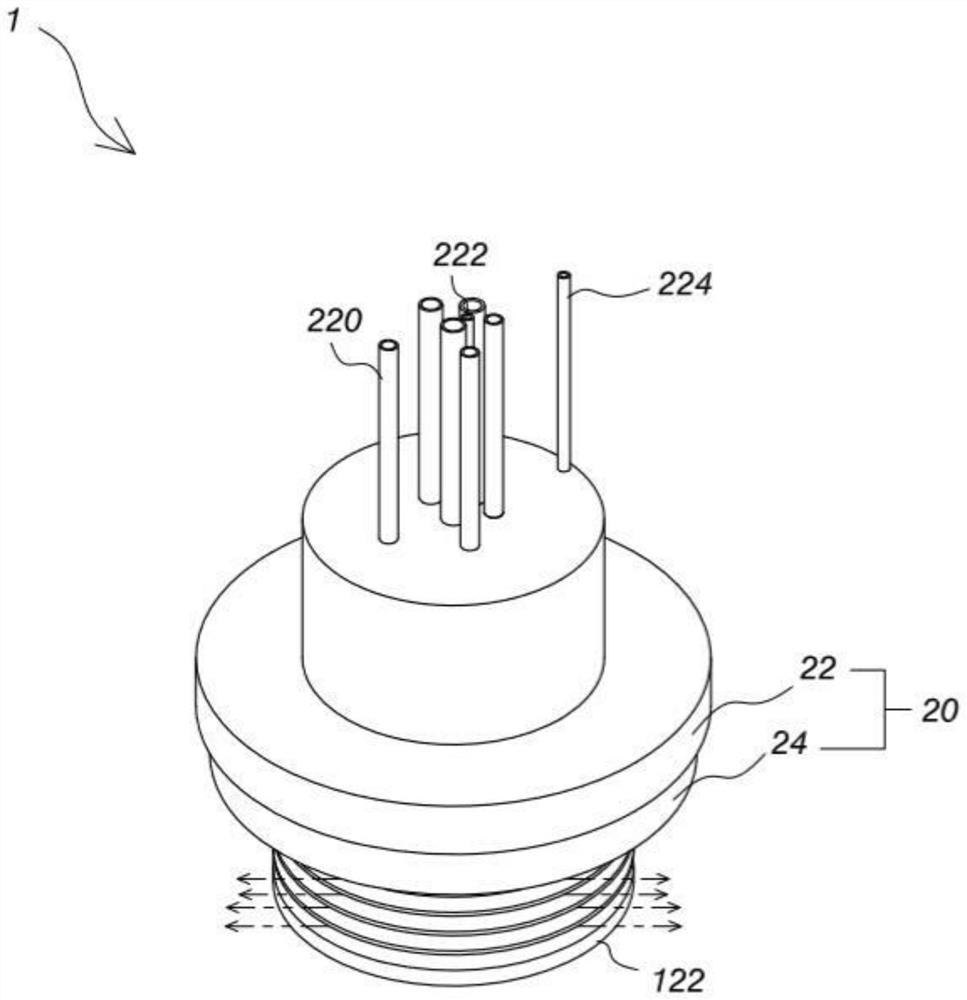

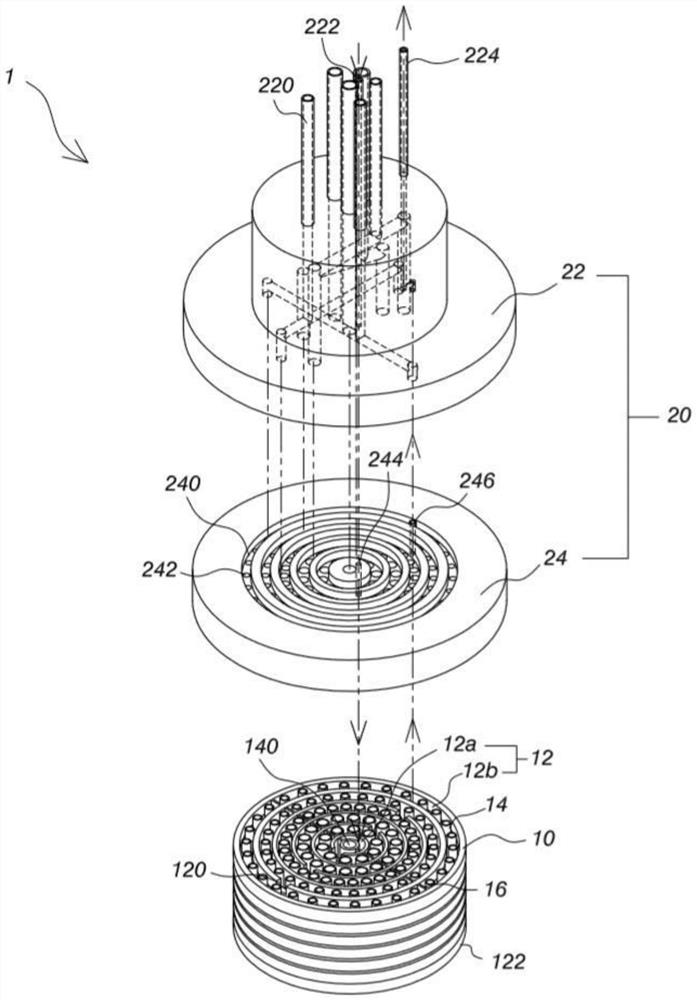

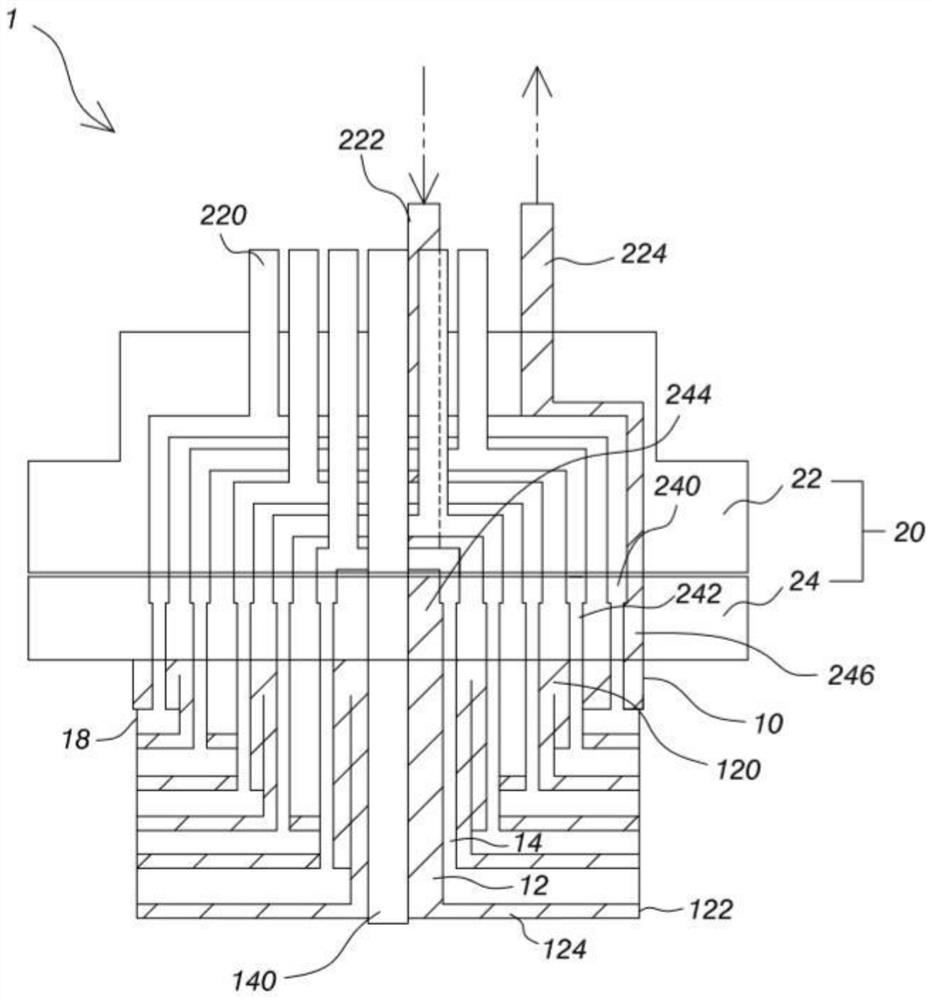

[0045] The multi-channel gas injector with serial cooling chamber of the present invention can be used to connect the output system of film deposition gas, so as to eject different gases as a shower head, thereby performing thin film deposition on wafers, and more importantly, it has a serial The special structural design of the multi-channel gas injector in the cooling chamber allows each exhaust pipe to be immersed in the cooling liquid to achieve the effect of controlling the temperature of the entire exhaust pipe.

[0046] Please refer to Figure 1 to Figure 3 , a multi-channel gas injector 1 with a series cooling chamber, including an injection housing 10 connected to an adapter 20 . In this embodiment, the injection casing 10 is a circular injection casing. Of course, the injection casing 10 can also be a square or triangular injection casing, and the shape is not limited. In this embodiment, the injection shell 10 is provided with multiple layers of cooling chambers 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com