Cooling system and method for hydrogen storage container of hydrogen refueling station

A technology for hydrogen storage containers and hydrogen refueling stations, which is applied to container filling methods, container discharge methods, pressure vessels, etc., and can solve problems such as excessive temperature rise, high temperature of hydrogen storage containers, hydrogen leakage and combustion, and achieve the elimination of safety hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

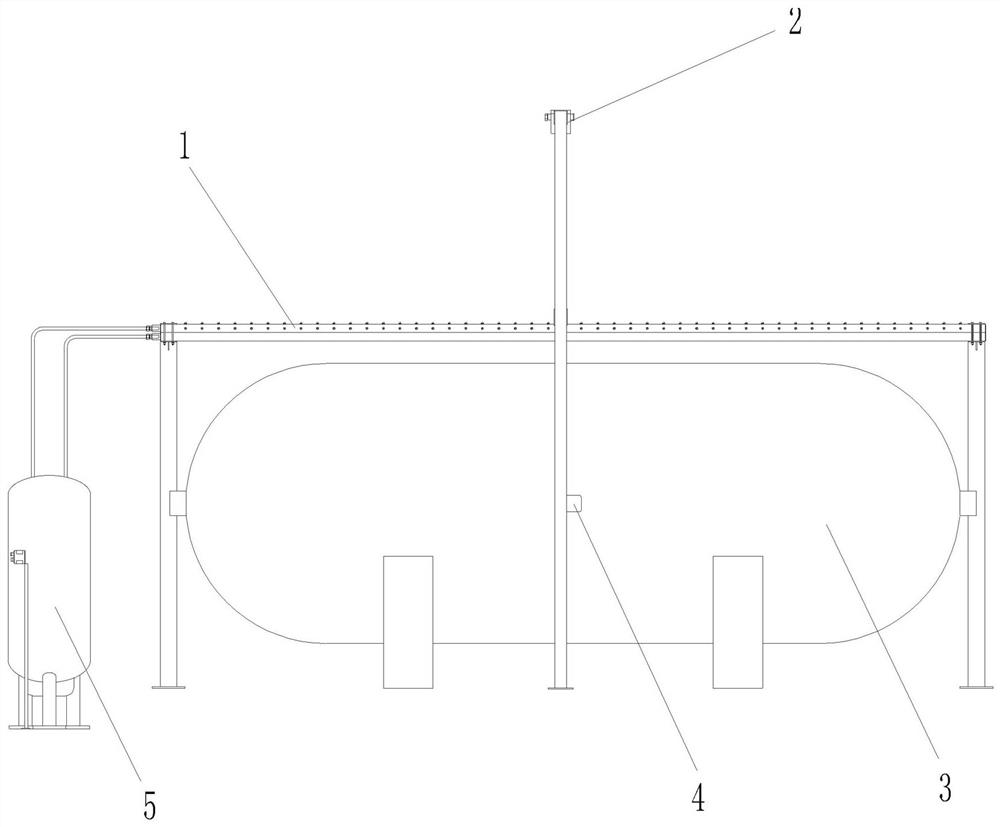

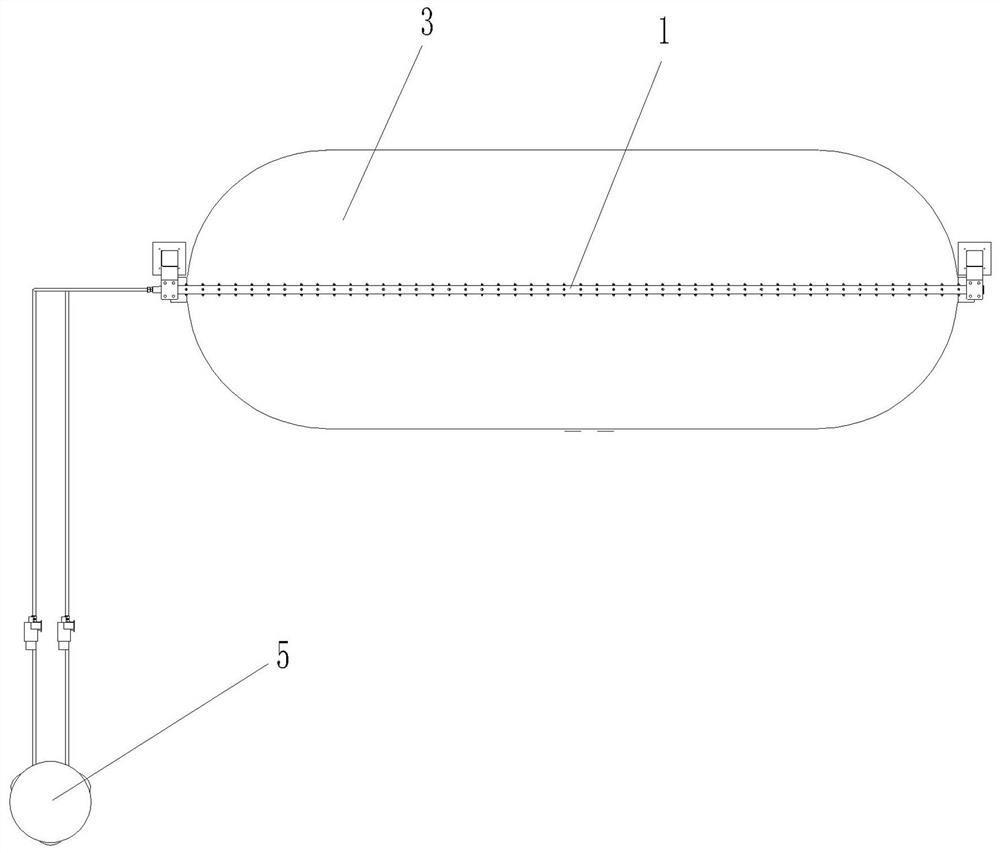

[0040] Embodiment 1: A hydrogen storage container cooling system for a hydrogen refueling station, see Figure 1 to Figure 7 ,include:

[0041] The spray mechanism includes an atomized water distribution chamber 20 arranged above the hydrogen storage tank 3, and a plurality of atomized nozzles 15 connected to the atomized water distribution chamber. The atomized water distribution chamber 20 is installed and used via a corresponding water supply The pipe and the spray electric ball valve are connected to the corresponding stabilized water supply system 5;

[0042] The spraying mechanism includes a spraying water distribution chamber 21 arranged above the hydrogen storage tank 3, and a plurality of spray holes 16 communicating with the spraying distribution water chamber 21, and the spraying distribution water chamber 21 passes through the corresponding water supply The pipe and the spray electric ball valve are connected to the stabilized water supply system 5; the atomizatio...

Embodiment 2

[0044] Embodiment 2 A method for cooling the hydrogen storage container of a hydrogen refueling station is implemented based on the arrangement of the hydrogen storage container cooling system described in Embodiment 1, see Figure 8 , Figure 9 , including the following steps:

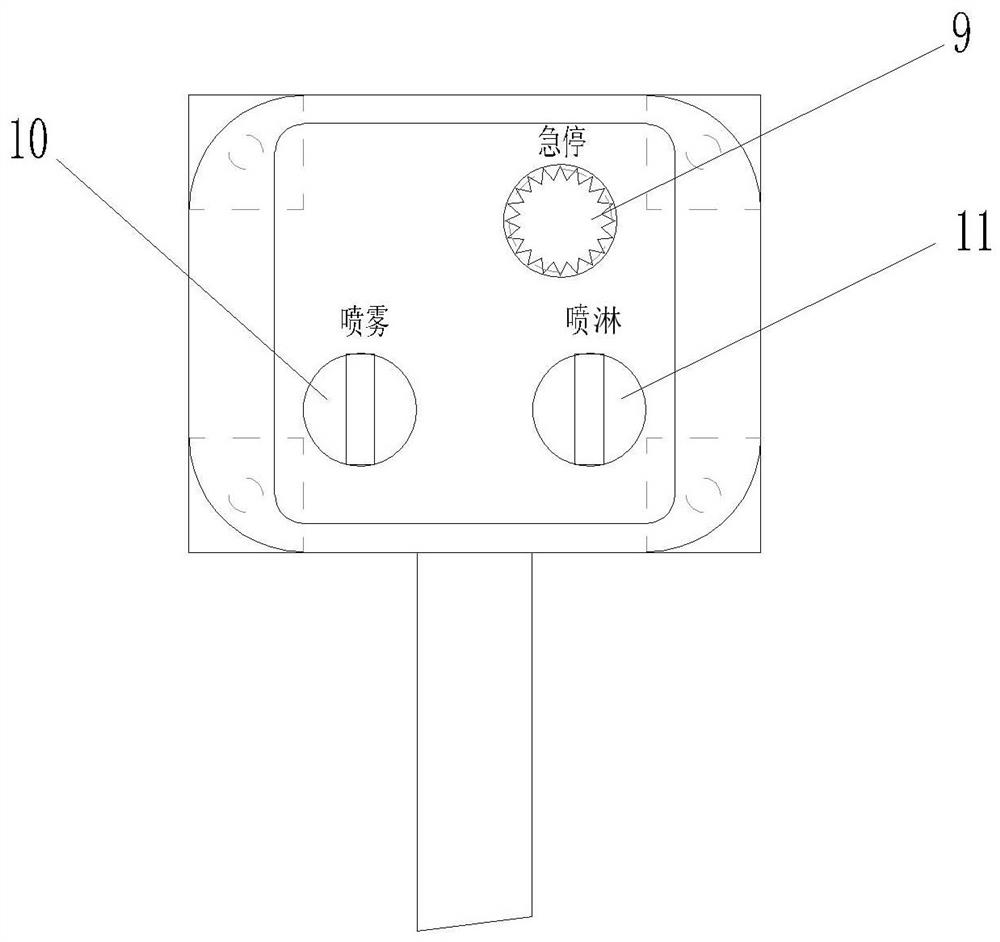

[0045] (1) Emergency stop control

[0046] Press the emergency stop button STP, the cooling system is in an emergency stop state, the system automatically closes the spray electric ball valve YV01 and the spray electric ball valve YV02, and generates an alarm message and sends out an alarm signal at the same time. Rotate the emergency stop button STP and pop up automatically, the emergency stop button STP is in the reset state, and the cooling system enters the automatic operation state.

[0047] (2) Spray control

[0048] see Figure 8 , turn on the spray knob switch SA01 on the explosion-proof operation column, the control unit controls to open the spray electric ball valve YV01, the cooling wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com