Workshop temperature and humidity monitoring automatic adjusting equipment

An automatic adjustment, temperature and humidity technology, applied in mechanical equipment, lighting and heating equipment, space heating and ventilation details, etc., can solve the problems of cumbersome adjustment work, large power consumption, high cost investment, etc., and achieve convenient and unified processing , prevent clogging, improve practicality and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

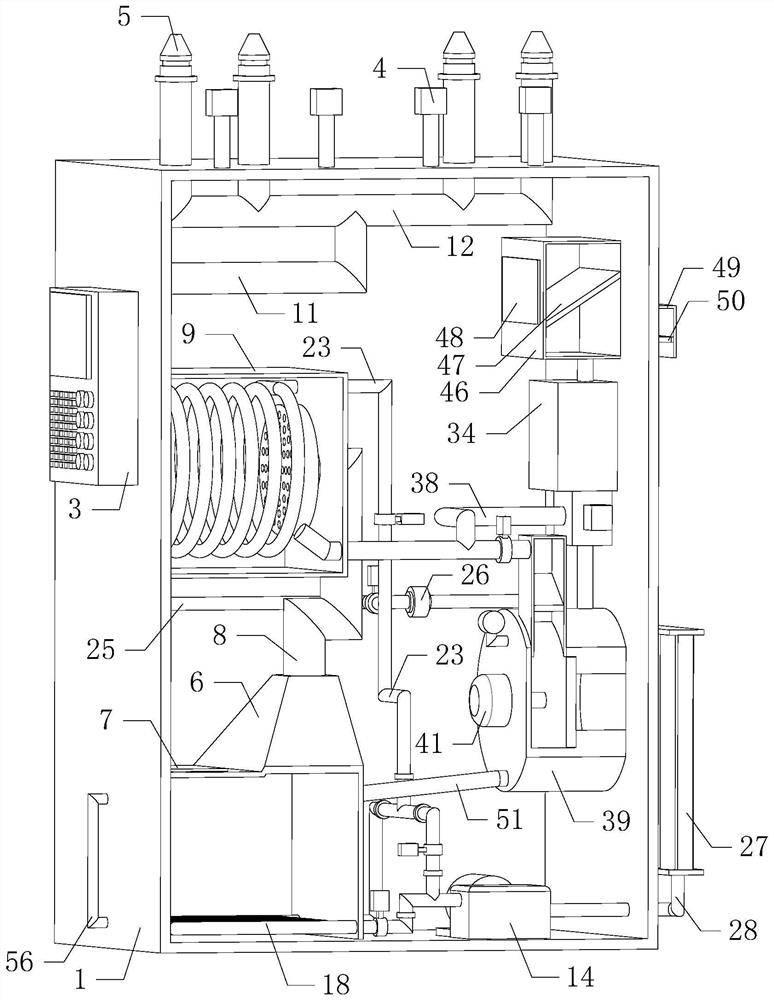

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

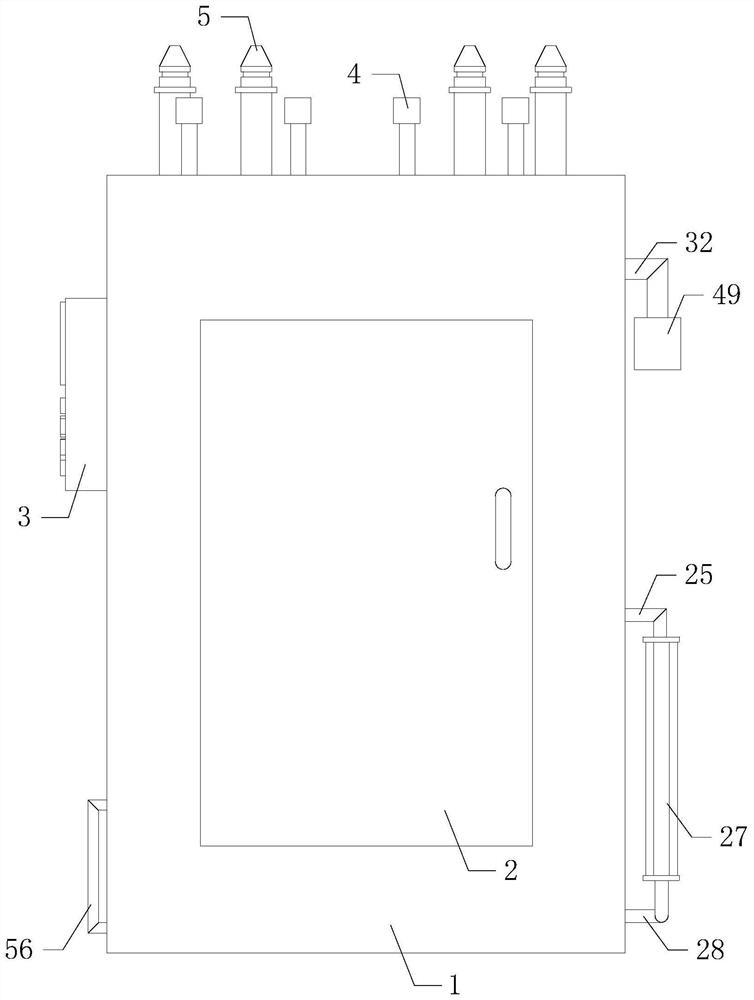

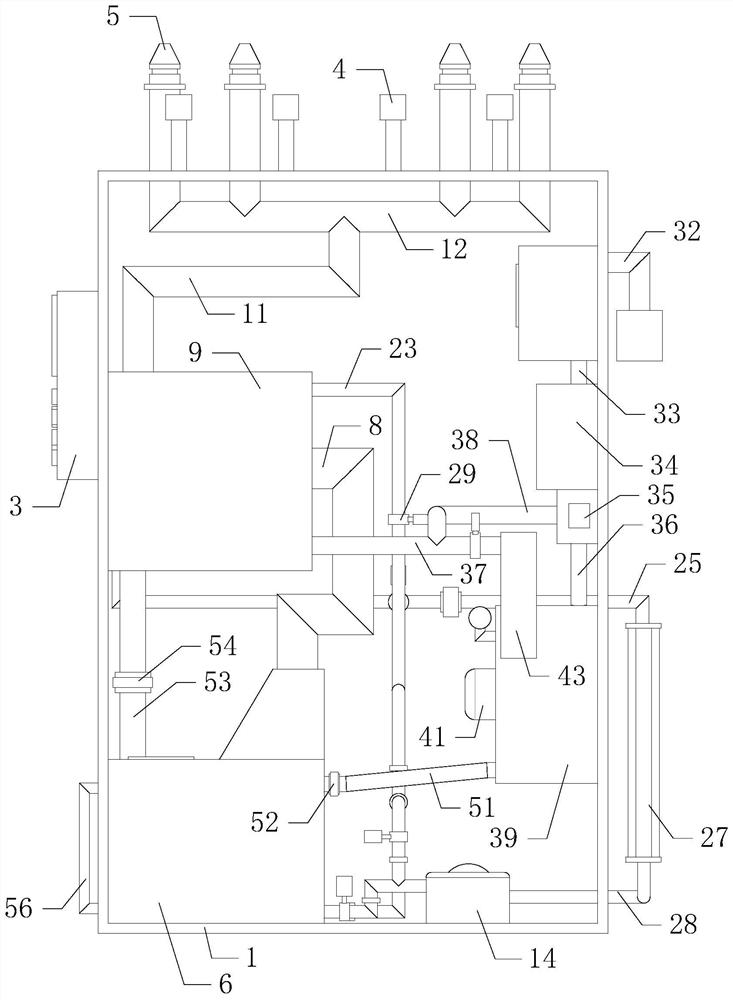

[0021] Such as Figure 1 to Figure 6As shown, the workshop temperature and humidity monitoring automatic adjustment equipment of the present invention, when it is working, multiple groups of temperature and humidity sensors 4 can detect the temperature and humidity of the air in the workshop in real time and transmit the detection signal to the central control box 3, inside the heat sink 27 Stored air, when the workshop needs to be heated and humidified, the central control box 3 controls to turn on the servo motor 13, the servo motor 13 drives the compressor 14 to run, and the compressor 14 puts the sixth conduit 28, the cooling fin 27 and the fifth conduit 25 The air is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com