A test system and test method for dynamic damage performance of water-containing fractures

A test system, crack technology, applied in the direction of testing material strength by using one impact force, testing material strength by applying stable tension/compression, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] In view of the shortcomings of the blasting simulation test method that blasting is difficult to quantify and carry out testing of water-containing fractured rock mass, the embodiment of the present invention provides a water-containing fracture dynamic damage performance test system and test method to study the dynamic damage of fractured rock mass and water in cracks during the blasting process. Pressure response and dynamic deformation, using non-explosive blasting method, using high-voltage pulse fracturing to quantitatively simulate blasting dynamics, realizing accurate simulation of blasting dynamics and quantitative characterization of water-containing fracture dynamic damage tests.

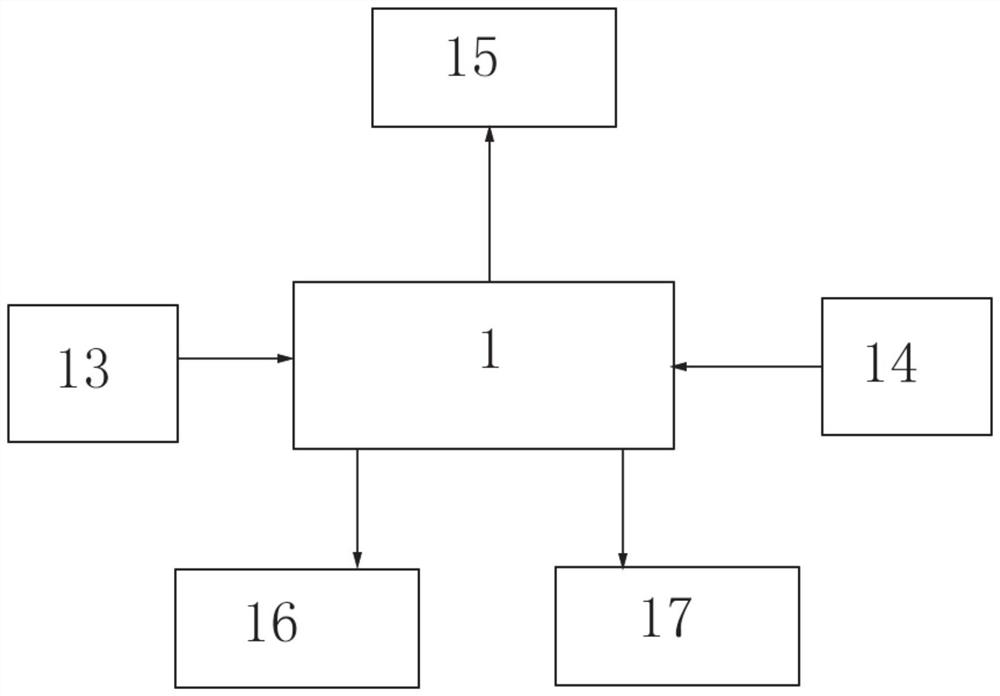

[0051] Such as figure 1 As shown, the water-containing fracture dynamic damage performance test system provided by Embodiment 1 of the present invention includes: a blasting dynamic simulation device 13, which is used to excite the rock specimen 1 by blasting to simulate the blasting...

Embodiment 2

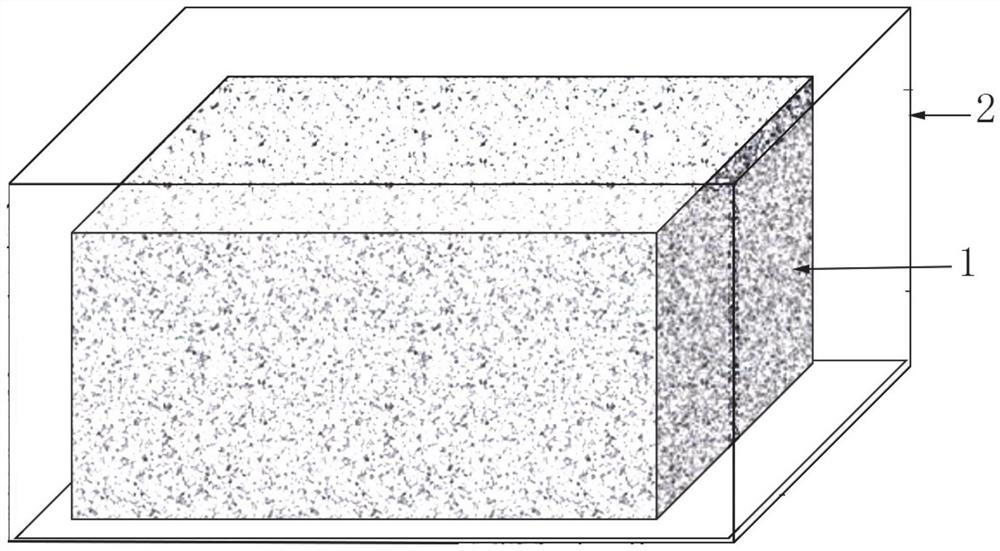

[0070] In embodiment 2 of the present invention, a kind of water-containing crack dynamic damage performance test system is provided, such as figure 2 As shown, the water-containing fracture dynamic damage performance test system includes: integrated pouring and protection device (namely protection device 2), blasting dynamic simulation and test device, water pressure loading and micro-change monitoring device in the crack, acoustic emission monitoring and high-speed camera device , the integrated pouring and protection device is respectively connected with the blasting dynamic simulation and testing device, the water pressure loading and micro-change monitoring device in the crack, and the acoustic emission monitoring and high-speed camera device.

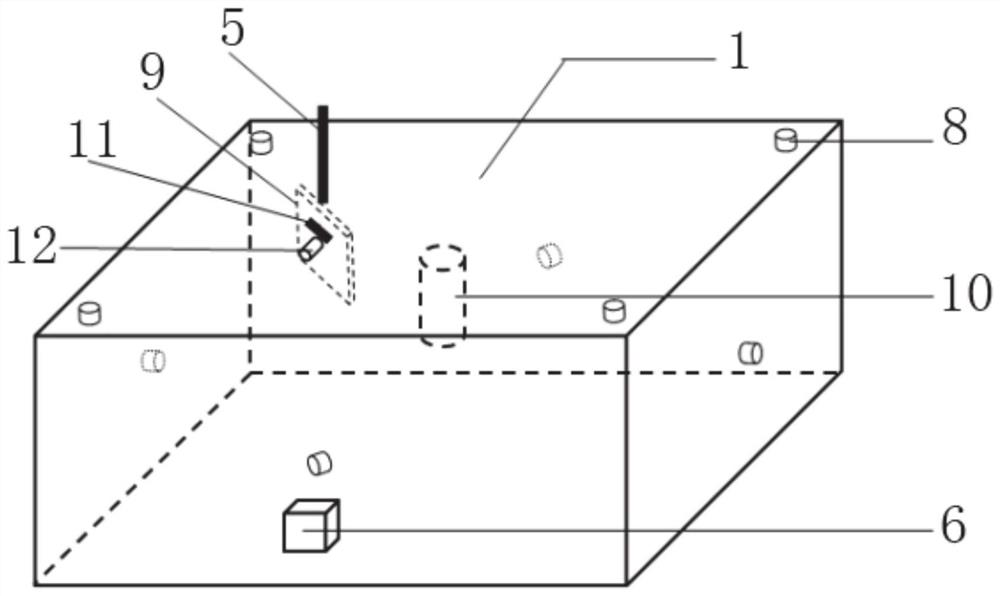

[0071] Such as Figure 3 to Figure 5 As shown, in this embodiment 2, the integrated pouring and protective device is high-strength explosion-proof tempered glass, integrated box structure, the test specimen is placed in the prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com