A Passive Waste Heat Removal System Based on Annular Air Cooler

A passive waste heat and waste heat discharge technology, applied in nuclear power generation, cooling devices, greenhouse gas reduction, etc., can solve the problems of high construction cost, complex liquid metal cooling reactor system, unsuitable for miniaturization and tight arrangement of reactors, etc. With good heat effect, the effect of enhancing radiation heat transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

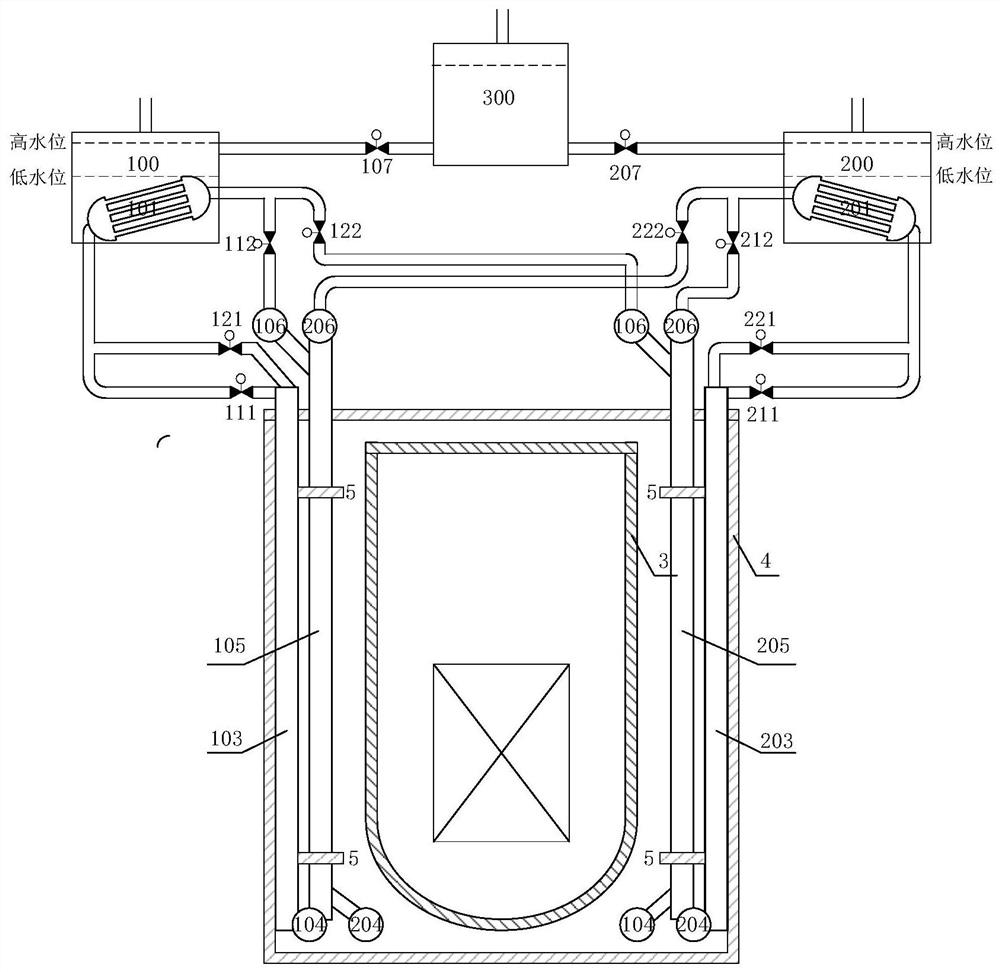

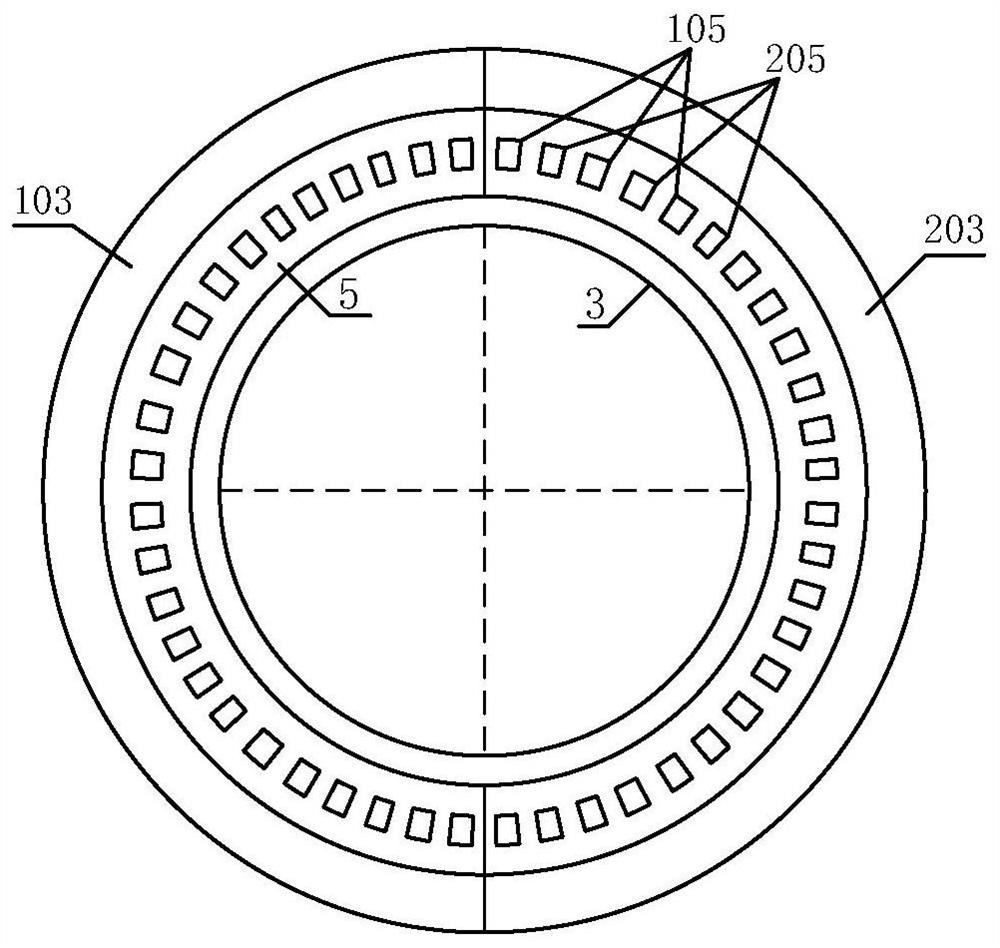

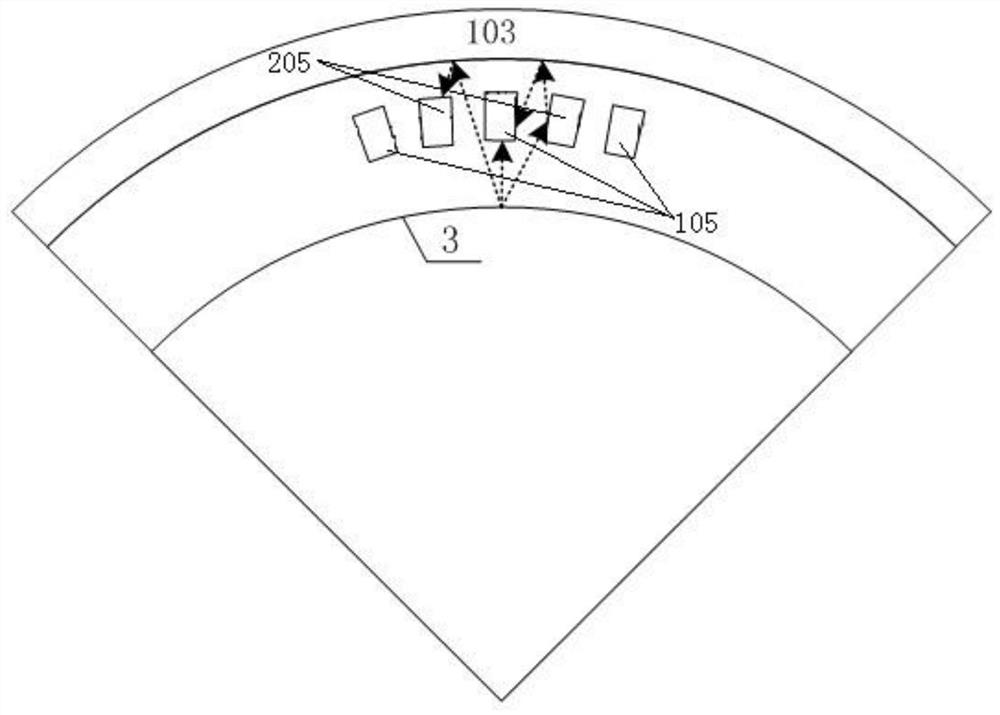

[0030] For ease of understanding, two waste heat removal subsystems are taken as examples for illustration. Such as Figure 1-Figure 3 As shown, it includes a first waste heat discharge subsystem and a second waste heat discharge subsystem, and the first waste heat discharge subsystem and the second waste heat discharge subsystem share a make-up water tank 300 .

[0031] Wherein, the first waste heat discharge subsystem includes a first annular air cooler, a first heat exchange device, and inlet electric valves 111 , 121 and outlet electric valves 112 , 122 of the first annular air cooler.

[0032] The second waste heat discharge subsystem includes a second annular air cooler, a second heat exchange device, and inlet electric valves 211 , 221 and outlet electric valves 212 , 222 of the second annular air cooler.

[0033] Specifically, after a normal or emergency shutdown, the shutdown signal triggers the opening of the outlet electric valve 112 or 122 and the inlet electric v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com