Deep junction composite terminal structure of high-voltage power chip and preparation method thereof

A compound terminal and power chip technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems such as large chip area, complex structure design of field plate plus field ring, and influence of VLD and JTE structure interface charges, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

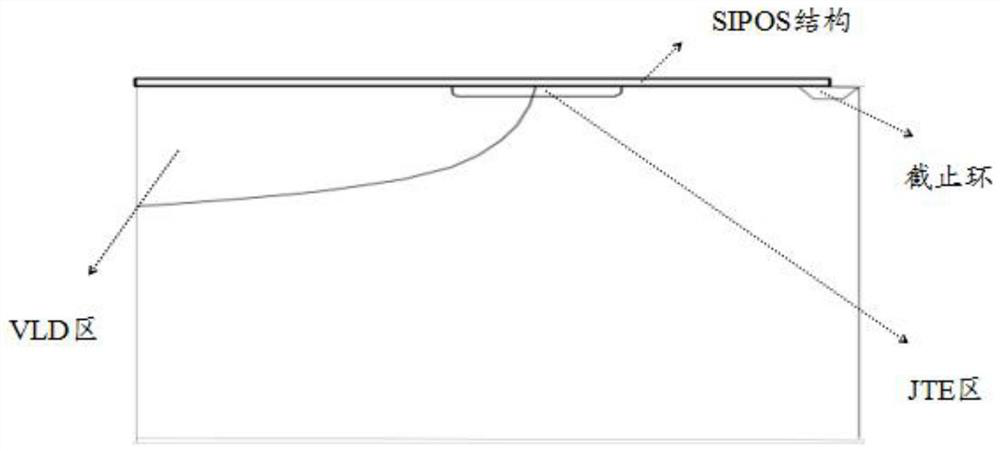

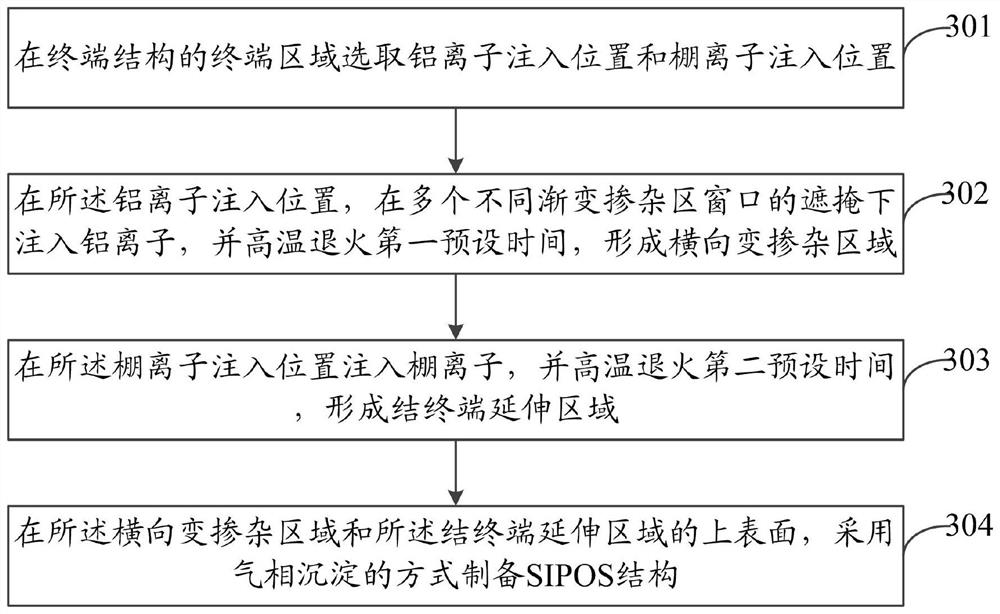

[0031] The purpose of the present invention is to provide a deep-junction composite terminal structure of a high-voltage power chip and its preparation method, so as to reduce the area of the terminal area, improve its terminal efficiency, and reduce the impact of interface charges on the breakdown voltage of the terminal structure.

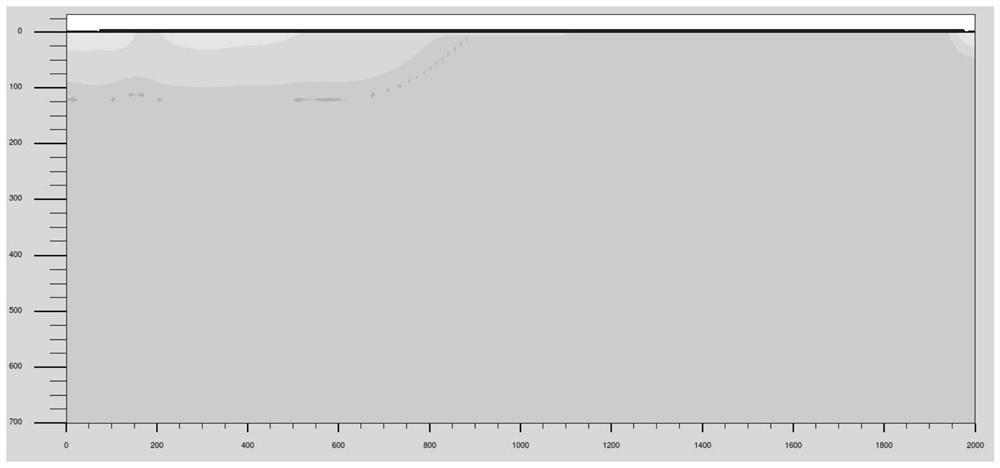

[0032] In order to make the above objects, features and advantages of the present invention more comprehensible, the invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] The insulating oxide film cannot effectively prevent the accumulation of charges on the surface of the device and ion contamination. These charges can induce charges of opposite polarity near the surface of the silicon substrate, which changes the electric field on the surface of the device, resulting in a change in the reverse breakdown voltage of the PN junction. .

[0034] The SIPOS structure has...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com