A kind of manufacturing method of igbt

A manufacturing method, N-type technology, applied in the field of IGBT manufacturing, can solve problems such as reducing the breakdown voltage of devices, and achieve the effect of strong practicability, easy use and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

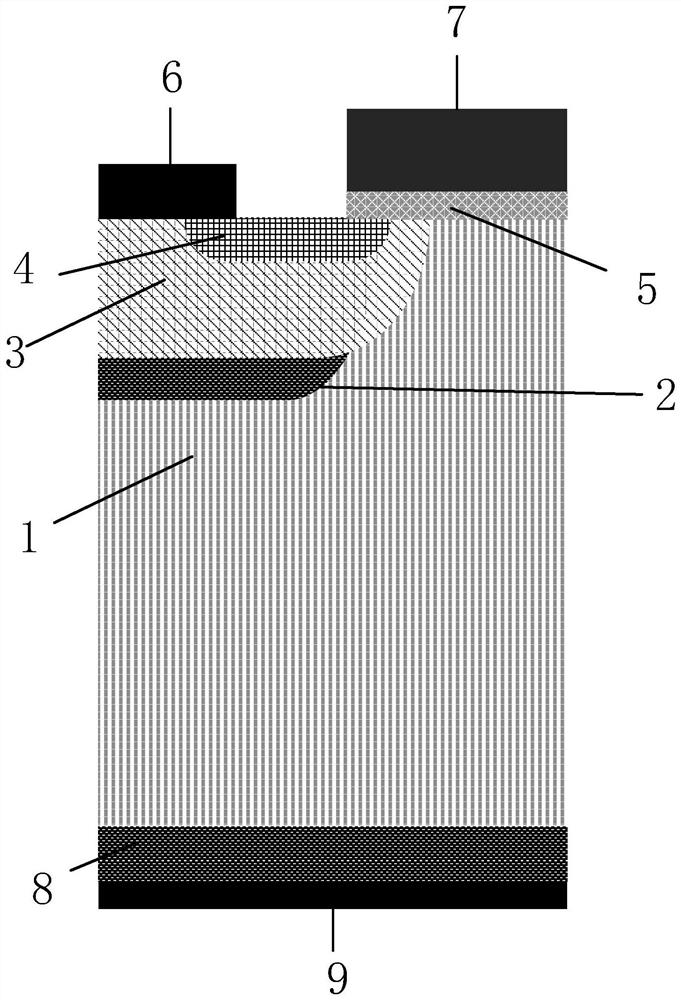

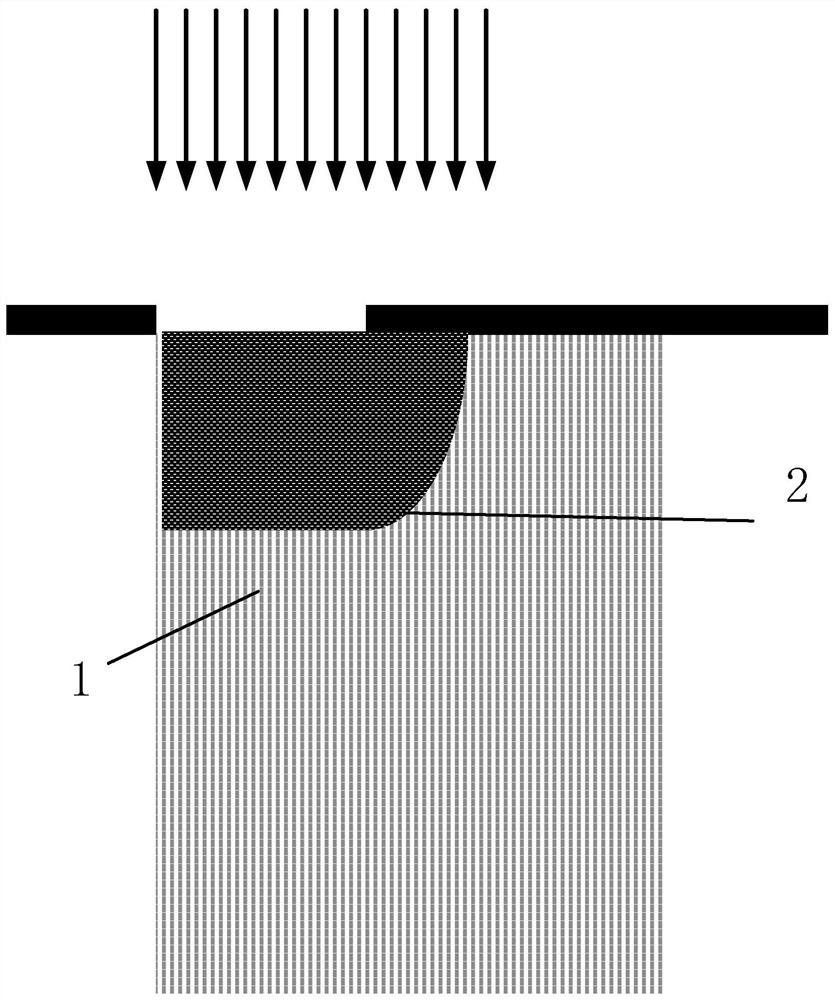

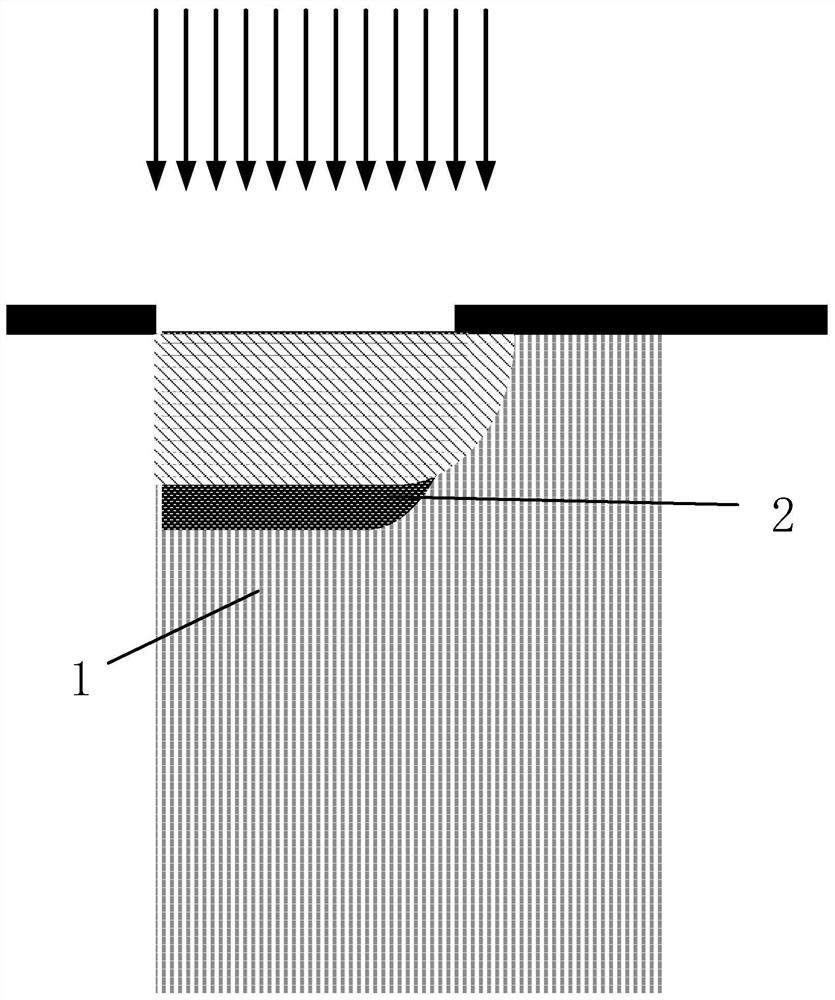

[0023] see Figure 1~3 , in an embodiment of the present invention, a method for manufacturing an IGBT includes the following steps: using an N-type single crystal silicon wafer to prepare an N-type substrate, and the N-type substrate is the N-drift region (1), and in the N-drift The upper surface of the region (1) forms an N+ minority carrier storage layer region (2), and then forms a P+ region (3) in the N+ minority carrier storage layer region (2), and the P+ region (3) completely covers the N+ minority carrier storage layer region (2) laterally. ) and does not completely cover the N+ minority carrier storage layer region (2) in the longitudinal direction, so as to achieve the purpose of only retaining the N+ minority carrier storage layer below the P+ region (3), and then normally form the front planar MOS structure, including the N+ source region (4) , gate oxide layer (5), emitter metal (6), gate metal (7) and other parts. Then, processes such as back thinning, implanta...

Embodiment 2

[0030] Taking the manufacturing process of 600V IGBT as an example, the specific process is as follows:

[0031] 1. Substrate material preparation, using an n-type zone-fused monocrystalline silicon substrate with a resistivity of about 40Ω·cm and a thickness of 400-600μm, and its crystal orientation is ;

[0032] 2. Forming an N+ doped region 2 on the N-drift region 1 by photolithography, implantation, and diffusion, and implanting a dose. Phosphorus implant dose is 1e13cm-3, implant energy is 100KeV, diffusion temperature is 1100°C, and diffusion time is 60 minutes.

[0033] 3. Form a lithography area larger than the N+ doping area. The width of the lithography opening in the P+ area is 2 μm to 6 μm larger than that in the N+ doping area. The P+ area 3 is formed in the N+ doping area 2 through the implantation and diffusion of boron. , the dose of boron implantation is 5e13cm-3, the implantation energy is 80KeV, the diffusion temperature is 1100°C, and the diffusion time is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com