Trench type super junction and manufacturing method therefor

A manufacturing method and super junction technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as poor reverse breakdown voltage uniformity, reduce filling time and cost, reduce time and cost, and in-plane uniformity improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Before describing the embodiments of the present invention, the influence of process mismatch on the breakdown voltage of existing trench-type super junction devices is introduced first:

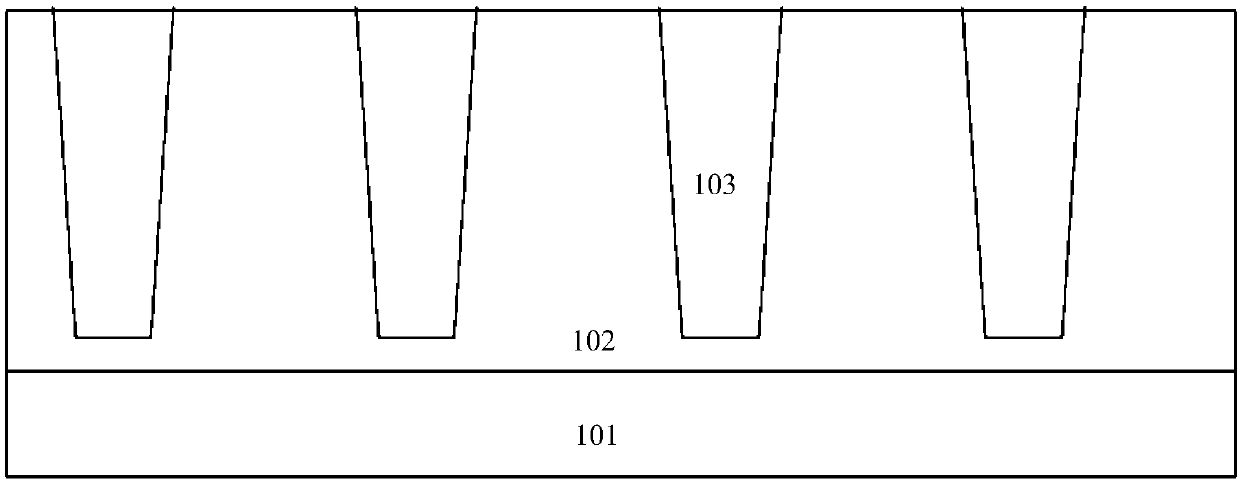

[0047] Such as figure 1 As shown, it is a schematic structural diagram of an existing groove-type super junction; an N-type epitaxial layer 102 is formed on the surface of an N-type semiconductor substrate such as a silicon substrate 101, and a plurality of trenches are formed in the N-type epitaxial layer 102. Each trench is filled with a P-type epitaxial layer 103, and the P-type epitaxial layer 103 filled in each trench forms a P-type thin layer, that is, a P-type column 103, and the N-type epitaxial layer between each P-type thin layer 103 Layer 102 constitutes an N-type thin layer. figure 1 The structure shown shows that the super junction is composed of a plurality of N-type thin layers and P-type thin layers 103 arranged alternately. figure 1 shows an alternate arrangement of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com