Concrete continuous output stirring device for road construction

A road construction and mixing device technology, which is applied in the direction of cement mixing device, clay preparation device, unloading device, etc., can solve the problems that the continuous mixing of concrete can not be realized and the output function can not be realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

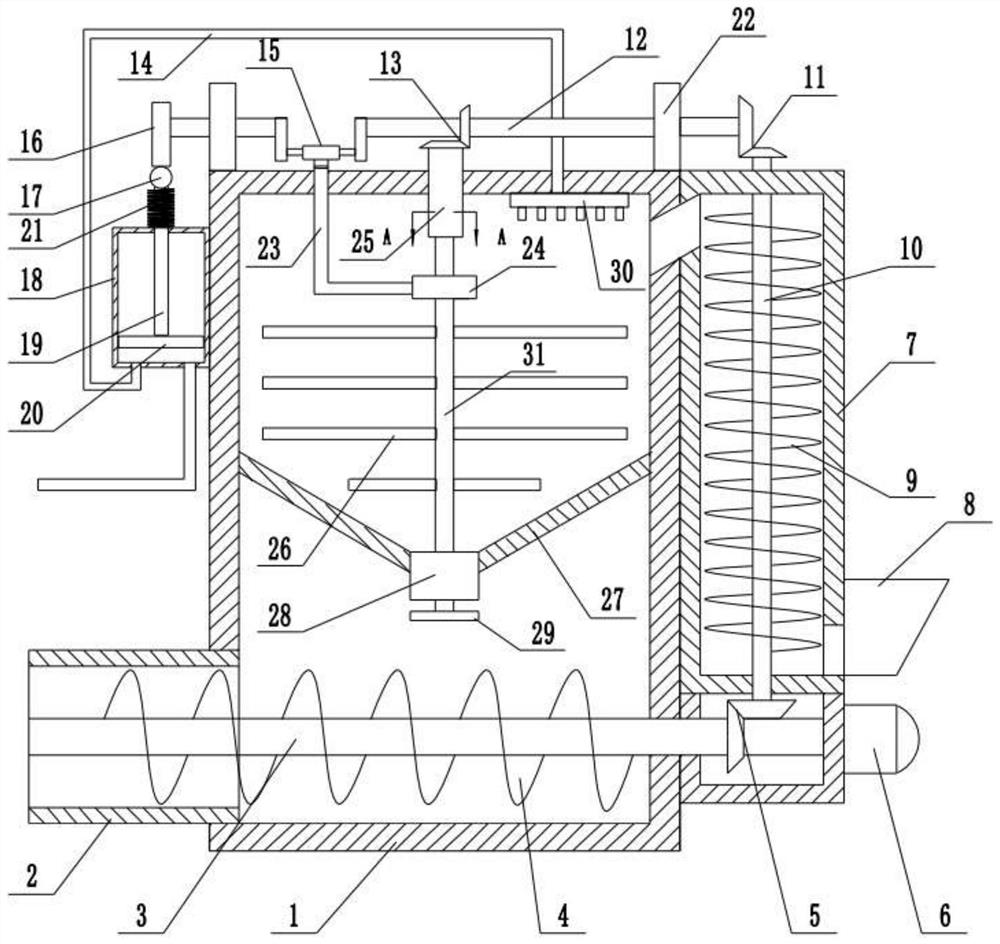

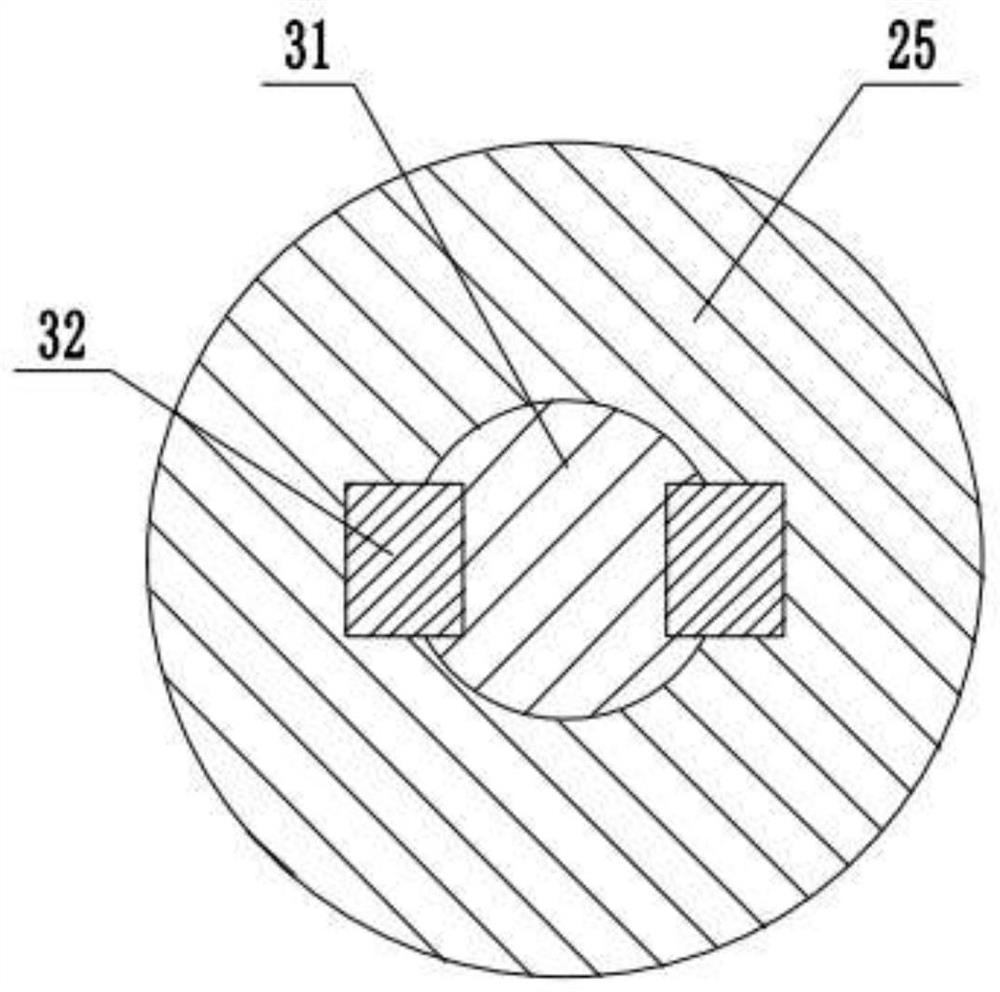

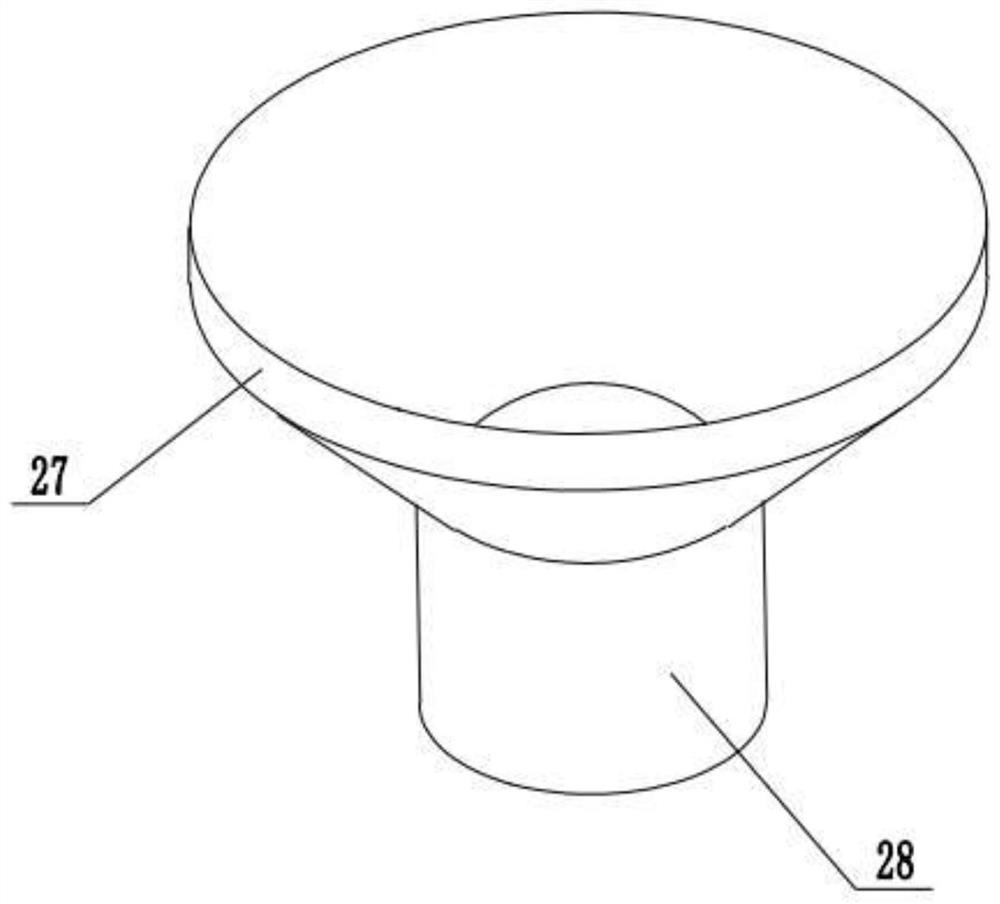

Embodiment 1

[0028] refer to Figure 1~3 , in an embodiment of the present invention, a concrete continuous output mixing device for road construction, comprising a mixing box 1, supporting frames 22 are installed on both sides of the upper end of the mixing box 1, and a drive shaft 12 is arranged to rotate between the supporting frames 22, and the A retaining ring 27 is installed inside the mixing box 1, thereby ensuring that the concrete material can effectively enter the interior of the feeding pipe 28, the bottom of the retaining ring 27 is equipped with a feeding pipe 28, and the right side of the mixing box 1 is equipped with a feeding cylinder 7, A feeding hopper 8 is installed at the bottom of the right side of the feeding cylinder 7, and the feeding hopper 8 communicates with the bottom of the feeding cylinder 7 to ensure that the external solid material is introduced into the feeding material 8, thereby flowing into the inside of the feeding cylinder 7, The feeding shaft 10 is in...

Embodiment 2

[0030] In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that, wherein, a feed screw 9 is installed on the outside of the feed shaft 10, which is used to realize that the concrete solid material passes through the feed cylinder The function of 7 is the introduction function to the inside of the mixing box 1.

[0031]The present invention, when working, first starts the driving motor 6, and the solid raw materials and liquid raw materials of the concrete are transported through the liquid introduction box 18 and the feeding cylinder 7, and the driving shaft 10 rotates at the same time, and the rotation is made under the action of the third gear set 13 The barrel 25 rotates, and the stirring shaft 31 drives the stirring blade 26 to rotate synchronously. On the other hand, with the cooperation of the L-shaped frame 23 and the crank mechanism 15, the stirring shaft 31 moves up and down while rotating, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com