High-strength flame-retardant soil-covering dust screen prepared from waste PVC, method and application

A dust-proof mesh, high-strength technology, used in cleaning methods and utensils, chemical instruments and methods, fire-retardant and flame-retardant filament manufacturing, etc., can solve the problems of thick dust-proof mesh and poor heat resistance, and achieve flame retardant performance. Good, improved quality and yield, the effect of a wide range of material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

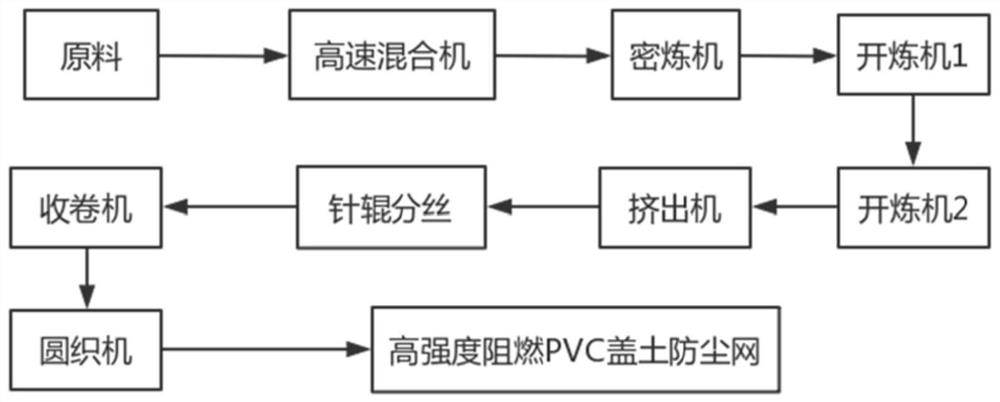

Method used

Image

Examples

Embodiment 1

[0050] A high-strength flame-retardant dust-proof net for covering soil prepared by using waste PVC, characterized in that the dust-proof net for covering soil includes construction waste PVC, a heat stabilizer, a flame-retardant plasticizer, a light stabilizer and an antioxidant ; Among them, heat stabilizer, flame retardant plasticizer, light stabilizer and antioxidant are respectively 3%, 40%, 1% and 0.5% of the quality of construction waste PVC.

[0051] (1) According to the ratio, add construction waste PVC raw materials, heat stabilizers, light stabilizers, antioxidants and flame retardant plasticizers into the high-speed mixer in the order of solid first and then liquid for mixing, and the temperature is controlled at 140 ℃, the stirring time is about 3.5min, and the stirring speed is about 700r / min to make the solid and liquid contact completely and mix evenly.

[0052] (2) Cool the material in step (1) and put it into an internal mixer for masticating, and process the...

Embodiment 2

[0064] Compared with Example 1, the mixing temperature of PVC raw material, anti-aging agent, flame retardant plasticizer, etc. in step (1) was changed from 140°C to 135°C, and other conditions remained unchanged.

Embodiment 3

[0066] Compared with Example 1, the stirring time of PVC raw material, anti-aging agent, flame retardant plasticizer etc. in the step (1) is changed from 3.5min to 4min, and other conditions remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com