High-silicon aluminum alloy and preparation method thereof

A high-silicon aluminum alloy and aluminum-silicon alloy technology, which is applied in the direction of improving process efficiency, can solve the problems of reducing the surface finish of machined parts, being susceptible to force peeling, and reducing the mechanical properties of the alloy, and achieves a good effect of primary silicon refinement. , Good organization refinement effect, simple and easy process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

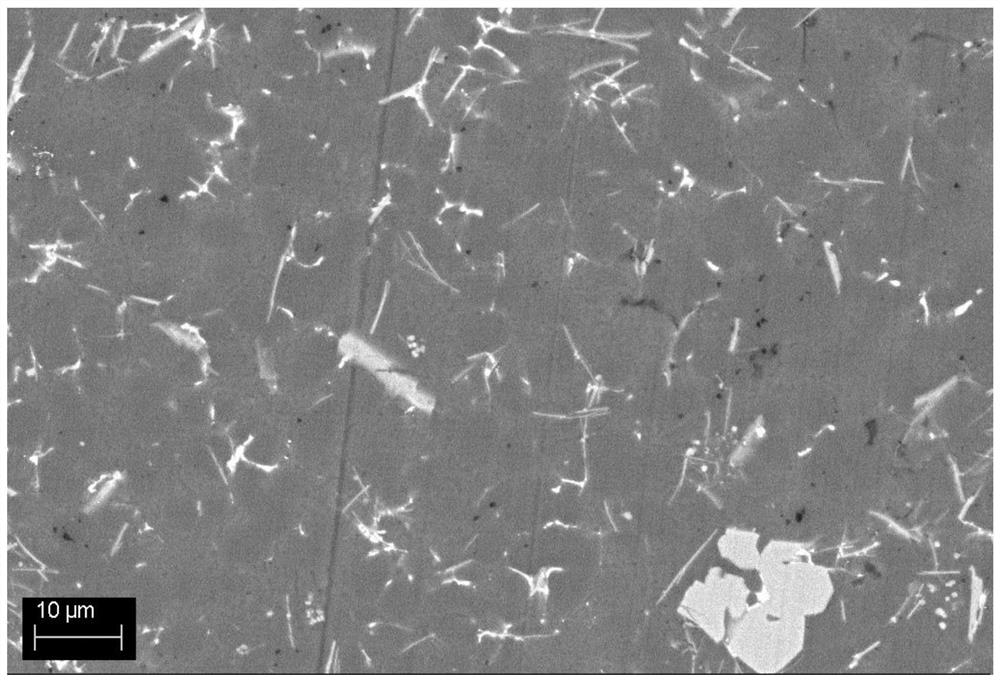

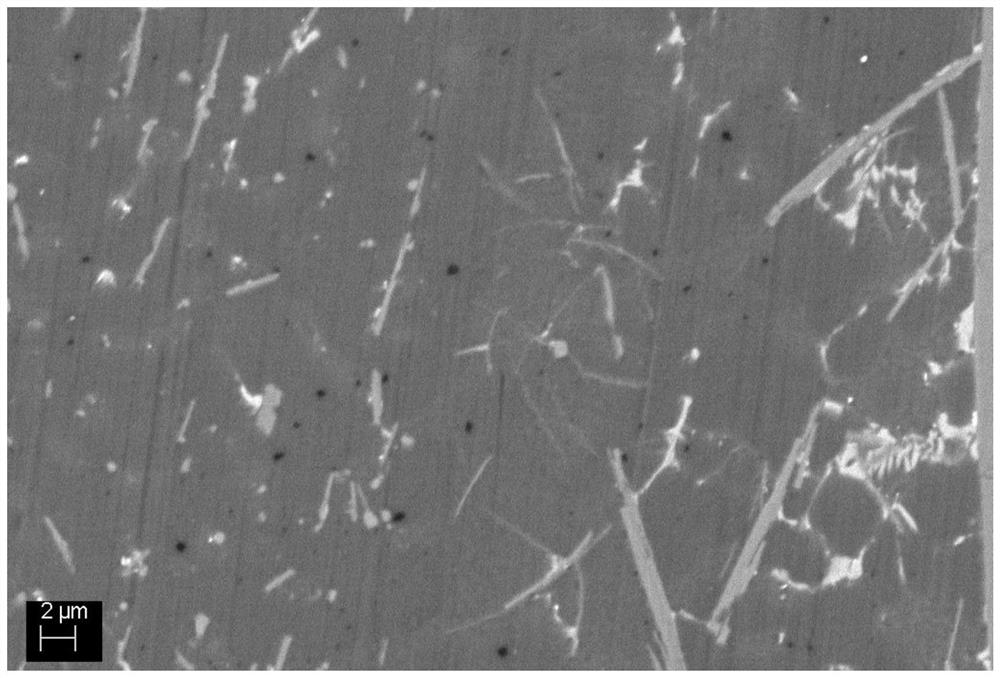

Examples

preparation example Construction

[0031] 1. Preparation method of high silicon aluminum alloy

[0032] A first aspect of the present invention provides a method for preparing a high-silicon aluminum alloy, comprising the following steps:

[0033] 1) Heat the aluminum-silicon alloy melt to above 650°C and keep it warm; in this step, the heating temperature is preferably controlled between 650°C and 680°C, and the holding time is not less than 30 minutes. Of course, the longer the holding time, the better the effect Good, for example: keep warm for 30min, 40min, 60min, 90min, 120min or longer;

[0034] 2), adding 3 to 8 wt% refining agent to the aluminum-silicon alloy melt obtained in step 1) while stirring, and then removing inclusions from the aluminum-silicon alloy melt obtained after refining; in this step, it is preferable to add the refining agent The content can be 3wt%, 5wt% or 6wt%, etc.; the time for stirring is not less than 30min, for example: stirring for 30min, 40min, 60min, 90min, 120min or longe...

Embodiment 1

[0041] A preparation method of high-silicon aluminum alloy, comprising the following steps:

[0042] 1) Heat the aluminum-silicon alloy melt to above 650°C and keep it warm for 30 minutes;

[0043] 2), adding 5wt% refining agent to the aluminum-silicon alloy melt obtained in step 1), stirring at the same time, standing for 30 minutes, and then removing inclusions from the aluminum-silicon alloy melt obtained after refining;

[0044] 3), add 3wt% Al-5Ti-1B refiner to the aluminum-silicon alloy melt obtained in step 2), stir, and then extend the tool head of the ultrasonic instrument into the stirred aluminum-silicon alloy melt for ultrasonic Treat for 30 minutes;

[0045] 4) Cooling the aluminum-silicon alloy melt obtained in step 3) to 620° C. to 650° C. and keeping it warm for 30 minutes, and then removing impurities and purifying the aluminum-silicon alloy melt.

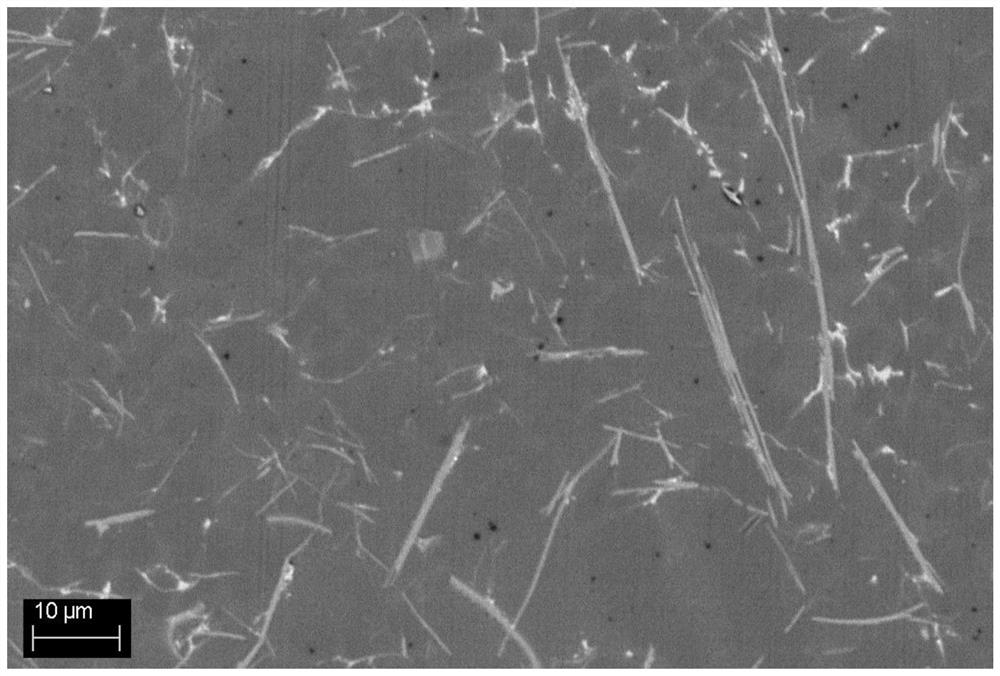

Embodiment 2

[0047] The difference with embodiment 1 is:

[0048] The ultrasonic treatment time is 60min.

[0049] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com