Adaptive fault monitoring method based on +/-x sigma boundary interval model

An interval model and fault monitoring technology, applied in simulators, character and pattern recognition, program control, etc., can solve problems such as difficult to use confidentiality, neglect of high-frequency data utilization, and high cost of algorithm implementation. Increase accuracy and reliability, easy-to-understand engineering promotion, and improve the effect of data utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

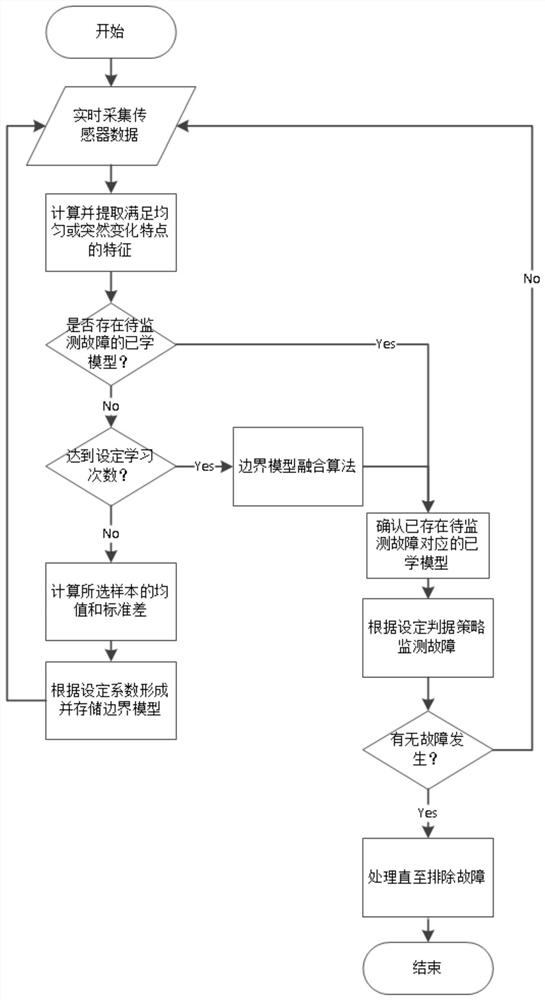

Method used

Image

Examples

Embodiment 1

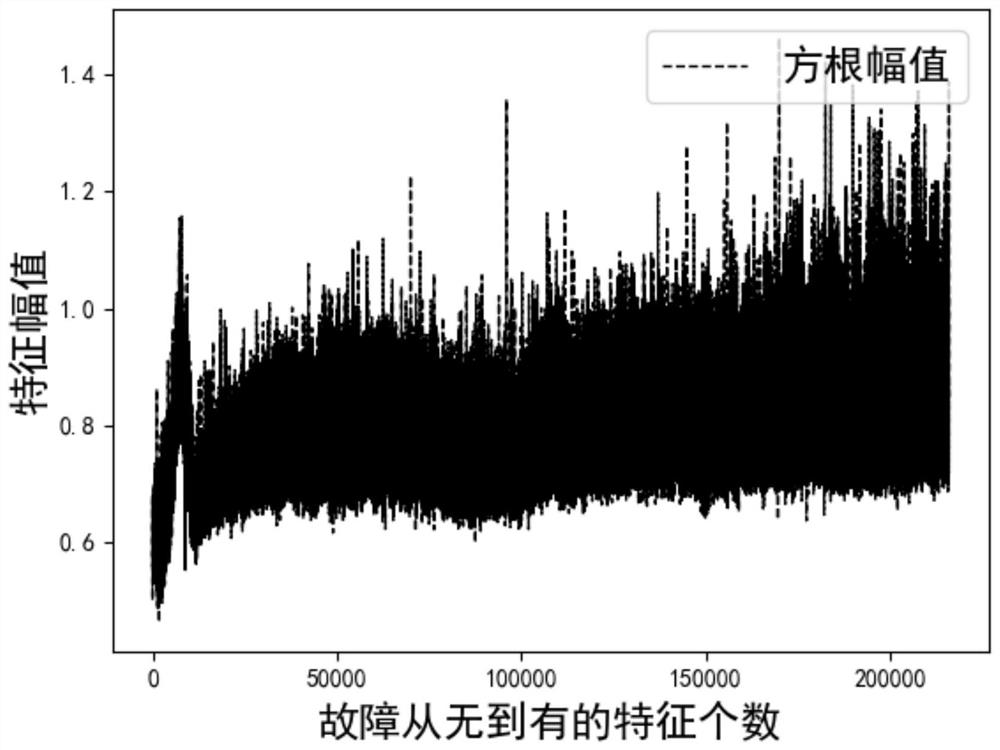

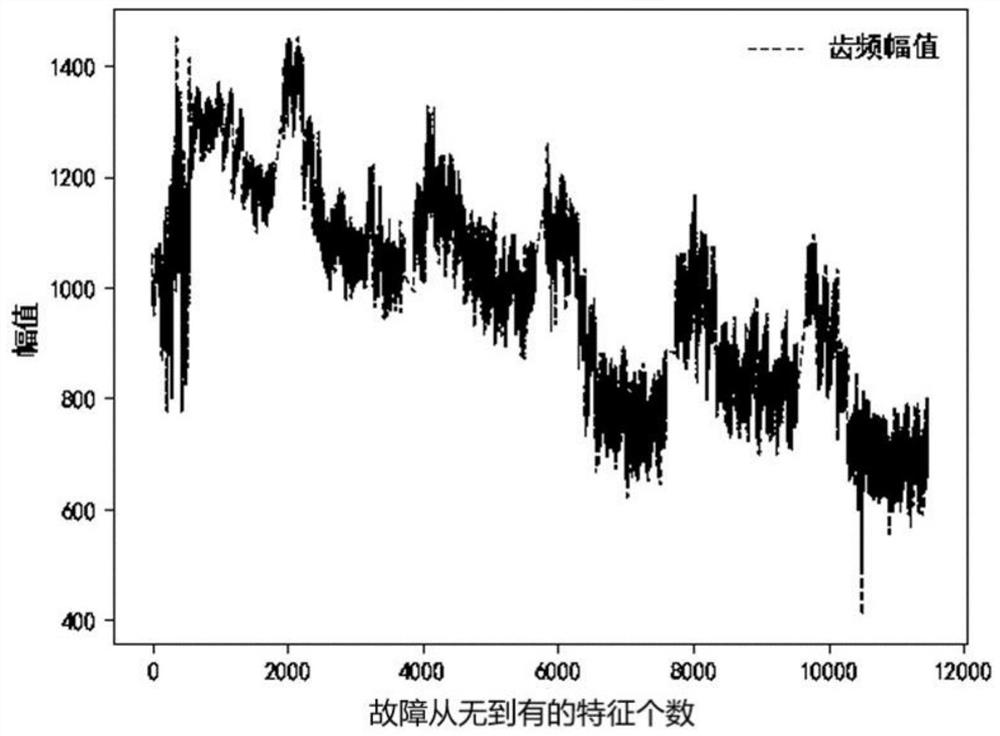

[0051] The effectiveness of the inventive method is illustrated with the tool wear on-line monitoring of machine tool processing, and concrete experimental condition is: cut on the VMC850 type vertical milling machining center that Shenyang machine tool factory produces, process a cuboid Q235 workpiece, be long 260mm, wide The diameter is 130mm and the height is 50mm; the tool used is an unused carbide 4-tooth end mill with a diameter of 12mm; the sampling frequency of the spindle motor current acquisition sensor is 3000Hz, and the sampling frequency of the acceleration sensor is 20KHz (X, Y , Z three-axis vibration signal and sound signal); this cutting experiment only includes one step of milling along the workpiece line, and the length of each milling is 220mm.

[0052] S1: preparation stage;

[0053] S1-1: Find features from any acquired signal, which has the characteristics of uniform increase or decrease with the occurrence of faults (sudden increase or decrease is not c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com