Full-automatic nutrition bowl loading and paving machine and working method thereof

A fully automatic technology for filling pots and laying machines, which is applied in botany equipment and methods, flowerpot filling, gardening, etc., and can solve the problems of manual soil filling and laying of nutritional pots, which are time-consuming and labor-intensive, so as to save manpower and improve Work efficiency, compact structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

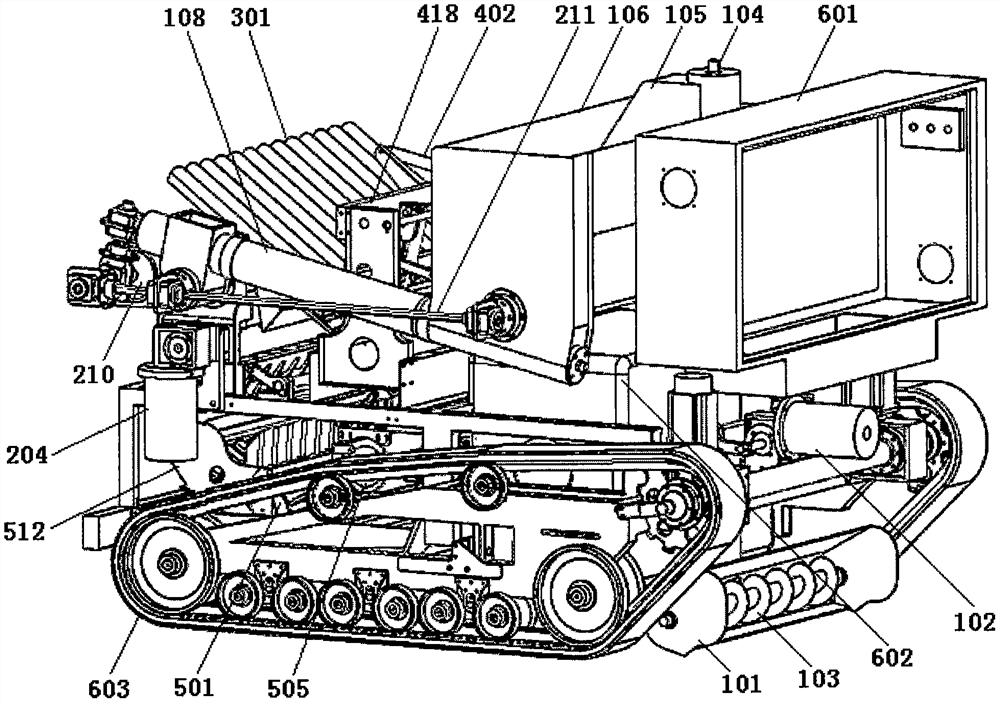

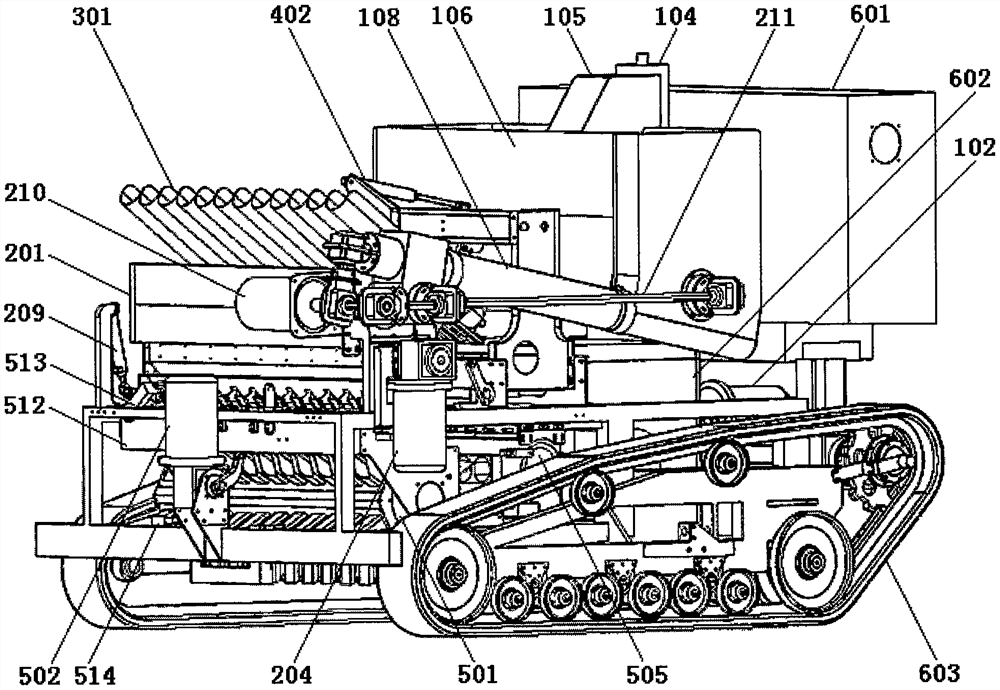

[0053] Embodiment 1: as Figure 1A , Figure 1B-Figure 11 As shown, the fully automatic nutrient bowl filling machine includes soil fetching system, soil dividing system, nutrient bowl storage, bowl taking system, soil loading and spreading system, electrical control system, walking system and power source:

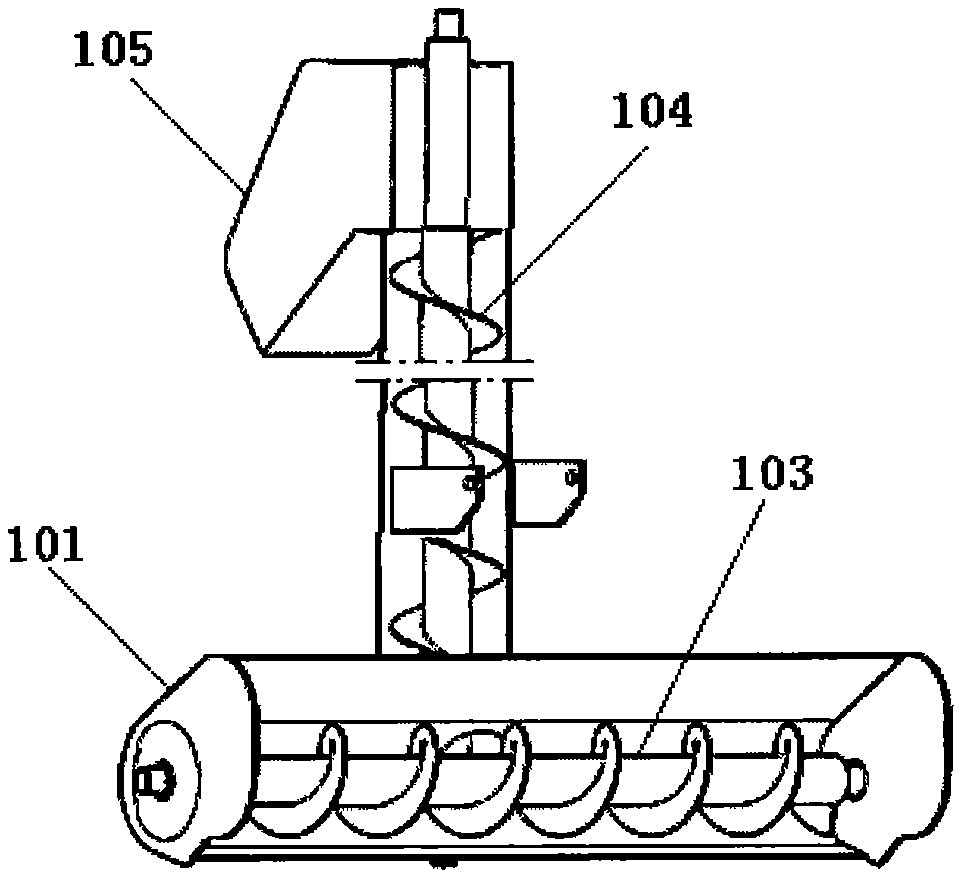

[0054] The soil extraction system includes the soil extraction shovel 101, the soil extraction shovel lifting motor 102, the soil extraction auger 103, the soil lifting auger 104, the soil delivery bucket 105, the soil storage box 106, the soil storage auger 107, and two soil storage sensors 109-1, 109-2, soil feeding auger 108, soil fetching shovel 101 is arranged under the front end of the complete machine, soil fetching shovel 101 is connected with a soil fetching shovel lifting motor 102 arranged on the front frame, and soil fetching shovel 101 The soil-borrowing auger 103 is horizontally arranged, and the exit position of the soil-borrowing shovel 101 rear is vertica...

Embodiment 2

[0075] Embodiment 2: the working method of full-automatic nutrient bowl dressing machine, comprises the following steps:

[0076] a. Equipment startup and bowl loading: such as Figure 1A , Figure 1B , Figure 5 As shown, the equipment is powered on and started, and the initial state of each unit is confirmed, and the stacked nutritional bowls are put downward into the semi-cylinder 301 of the nutritional bowl storage;

[0077] b. Take soil into the storage box: if Figure 1A-Figure 4 As shown, when the soil storage shovel 101 is judged according to the soil storage sensor 109-2 of the lower limit when the soil storage in the soil storage box 106 li is too low, the soil extraction shovel 101 is driven by the soil extraction shovel lifting motor 102 and falls to the ground. The soil on the ground is shoveled in, and the soil auger 103 and the soil auger 104 rotate simultaneously, and the soil auger 103 constantly pushes the soil shoveled into the soil auger 104, and the soil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com