A kind of comprehensive sterilization thermos cup and using method thereof

A thermos cup and comprehensive technology, applied in the field of thermos cups, can solve the problems that thermos cups cannot be carried with paper towels, increase the user's carrying burden, and have single function of thermos cups, and achieve the effects of improving convenience, saving space and increasing convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

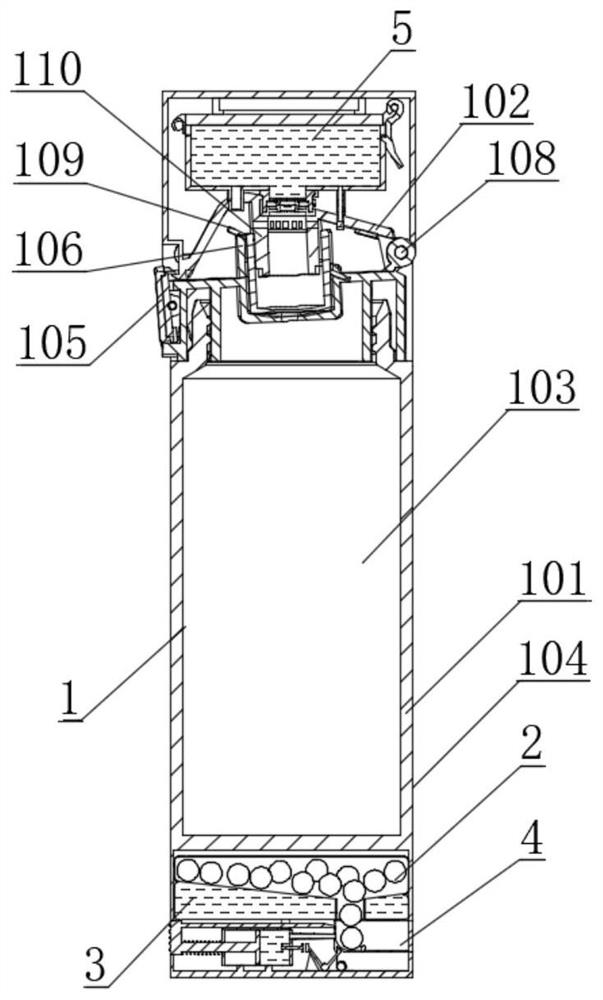

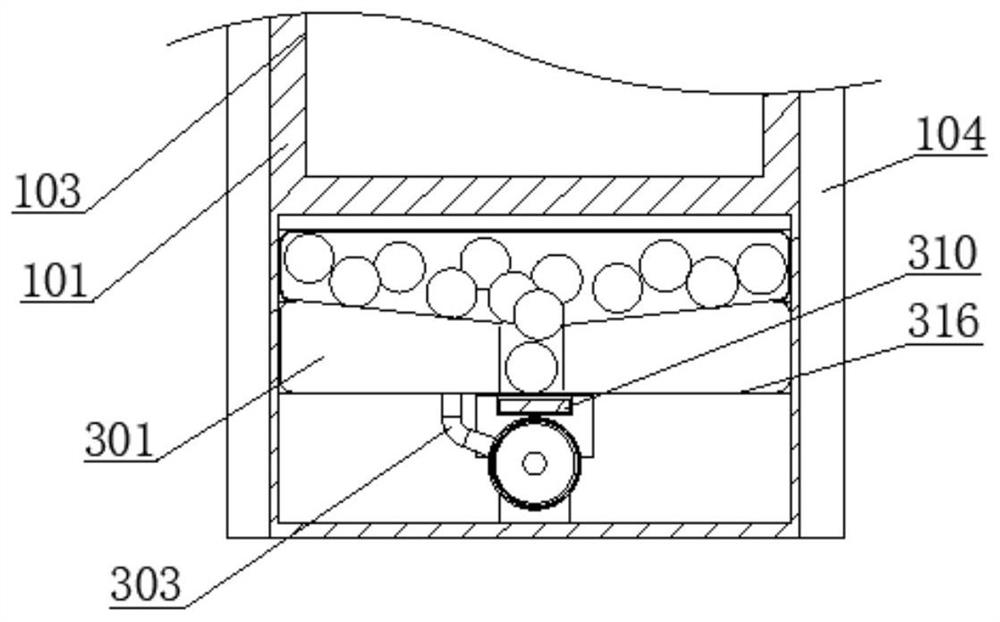

[0058] like figure 1 As shown, a comprehensive sterilization thermos cup includes a cup body assembly 1, a paper ball assembly 2, a liquid application assembly 3, a drawer assembly 4 and an atomization assembly 5. The paper ball assembly 2, the liquid application assembly 3 and the drawer assembly 4 are installed in The inner bottom of the cup body assembly 1, the atomization assembly 5 is installed on the top of the cup body assembly 1, the paper ball assembly 2 is installed on the liquid dispensing assembly 3, and the liquid dispensing assembly 3 is connected with the drawer assembly 4.

[0059] like figure 1 , Figure 12 As shown, the cup body assembly 1 includes a main body 101, a cup lid inner top 102, a water cup switch 105, a drinking port 106, a cup lid connector 108, a cup mouth plug 109, a cup mouth fixing post 110 and a cup lid body 111, and the top of the main body 101 There is an opening, the lid body 111 is rotatably connected and sealed with the top of the mai...

Embodiment 2

[0077] In addition to the structure in the above-mentioned Embodiment 1, this embodiment also has the following features:

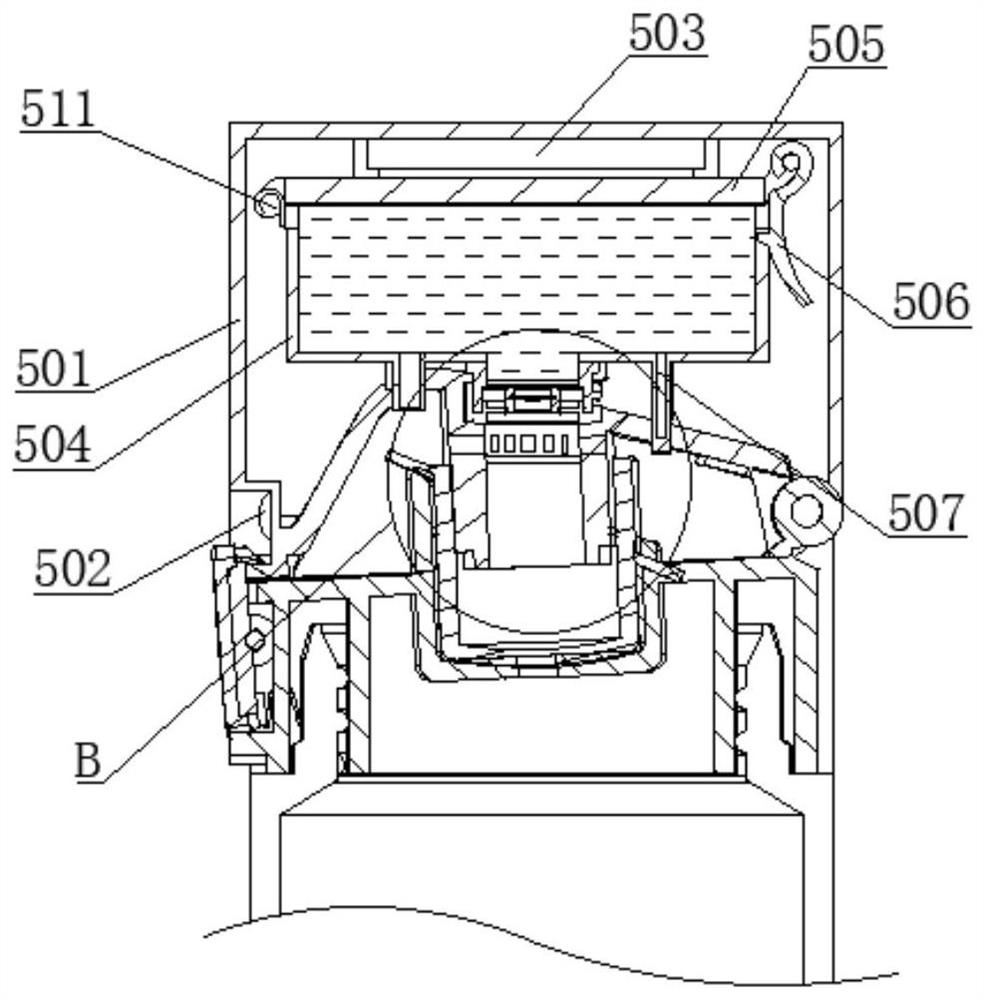

[0078] like image 3 , Figure 4 As shown, the atomization assembly 5 also includes an atomization box cover 505, an atomization box switch 506, a blocking sheet 509 and an atomization box connector 511, and the atomization box cover 505 is connected to the atomization box 504 through the atomization box connector 511. , the atomizing box switch 506 is fixedly connected with the atomizing box cover 505 , and the blocking sheet 509 is arranged inside the fixing column 110 and below the plurality of mist outlet ports 510 .

[0079] The setting of the atomizing box cover 505, the atomizing box switch 506 and the atomizing box connector 511 realizes that the atomizing box 504 can be opened, the edible sterilizing liquid in the atomizing box 504 can be added, and the barrier sheet 509 can effectively help the atomization The edible sterilizing liquid flows o...

Embodiment 2

[0086] The advantage of the second embodiment over the first embodiment is that the settings of the atomizing box cover 505 , the atomizing box switch 506 and the atomizing box connector 511 realize that the atomizing box 504 can be opened, and the atomizing box 504 can be added. For edible sterilization liquid, the blocking sheet 509 can effectively help the atomized edible sterilization liquid flow out and improve the reliability of the device; Sterilization, the bactericidal coating on the outer wall 104 can sterilize the palm of the person and other places that contact the outer wall 104, further expand the scope of sterilization of the thermos cup, and improve the hygiene and cleanliness of the user; the bottom plate 316 is a hard bottom plate, and the bottom plate 316 can be fixed Installed inside the main body 101, the liquid storage bag 317 is made of soft material, which can facilitate the sterilization liquid to enter the liquid outlet 315 along the connecting pipe 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com