Concentration detection circuit, disinfectant manufacturing machine and control method of disinfectant manufacturing machine

A technology of concentration detection and control method, which is applied in disinfection, sanitary equipment for toilets, water supply devices, etc., can solve the problems of slow electrolysis efficiency and waste of electric energy, and achieve the effect of preventing water overflow and improving user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

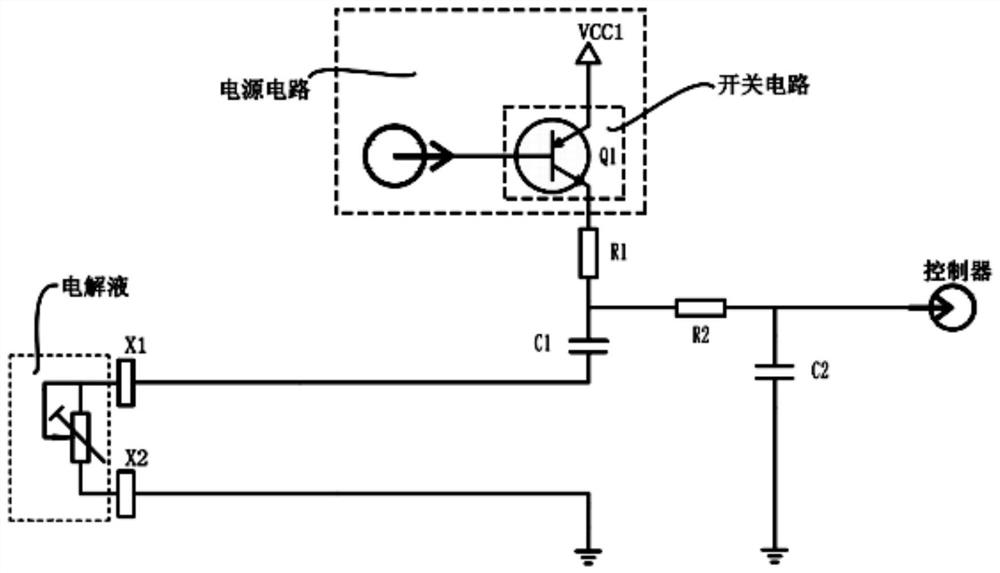

[0050] Such as figure 1 As shown, the embodiment of the present invention provides a concentration detection circuit, which includes: a first conductive terminal X1, a second conductive terminal X2, a sampling load, a power supply circuit and a controller.

[0051] The first conductive terminal X1 is connected to the first section of the sampling load, and the first conductive terminal X1 is suitable for extending into the electrolyte. The second conductive terminal X2 is connected to the reference ground, and the second conductive terminal X2 is suitable for extending into the electrolyte. The power supply circuit is connected to the second end of the sampling load through the first resistor R1, and the output voltage range of the power supply circuit can be adjusted periodically. The input end of the controller is connected with the second end of the sampling load, and the concentration of the electrolyte is calculated according to the input voltage of the sampling load.

...

Embodiment 2

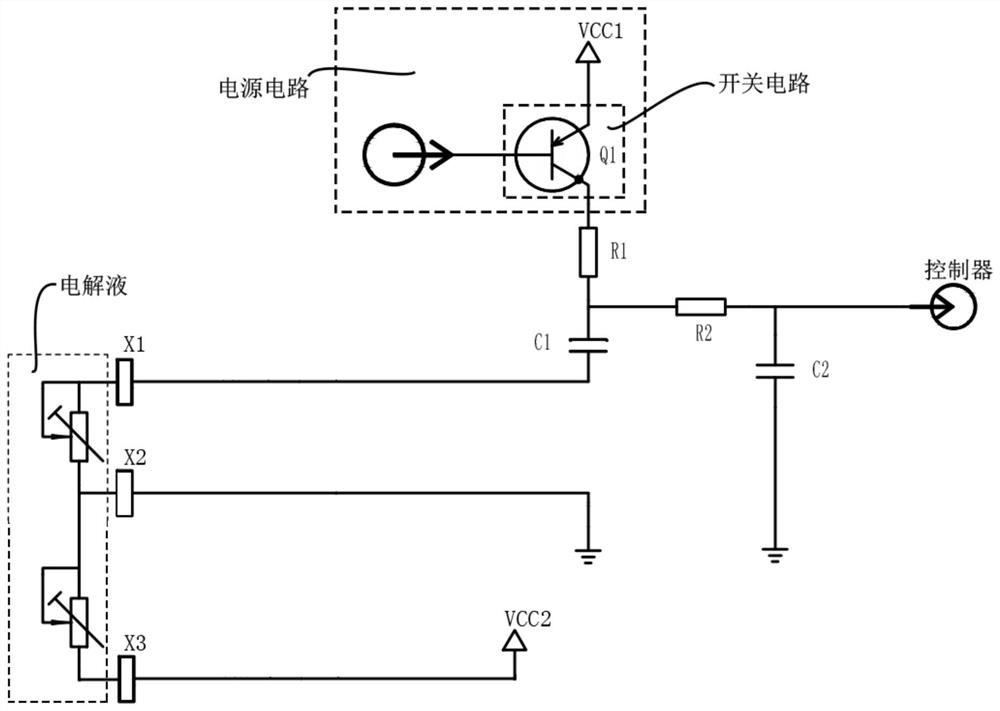

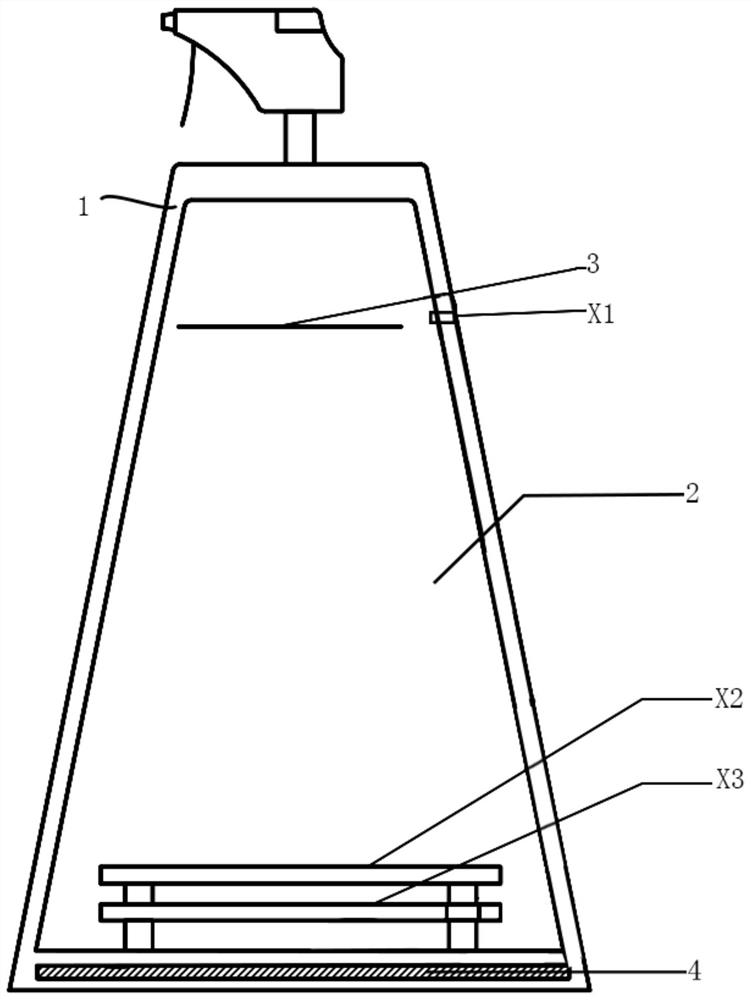

[0061] Such as figure 2 with image 3 As shown, the embodiment of the present invention also provides a disinfectant manufacturing machine, including a housing, a third conductive terminal X3, and the concentration detection circuit described in any one of the above embodiments, the concentration detection circuit includes the first conductive terminal X1 , the second conductive terminal X2, a power circuit and a controller.

[0062] In the embodiment of the present invention, the housing 1 has a cavity 2 suitable for containing the electrolyte, the concentration detection circuit is arranged on the housing, and the first conductive terminal X1 and the second conductive terminal X2 are suitable for extending into the electrolyte. The controller can be arranged in a predetermined accommodation chamber of the casing, and a sealing structure is provided between the accommodation chamber and the cavity. In this way, the volume of the disinfectant making machine can be reduced. ...

Embodiment 3

[0072] Such as Figure 4As shown, the embodiment of the present invention also provides a control method of the disinfectant solution manufacturing machine, and the control method is applied to the disinfectant solution production machine described in any of the above-mentioned embodiments. This control method includes:

[0073] S1. Obtain the initial concentration of the electrolyte;

[0074] S2. According to the relationship between the preset electrolyte concentration and the electrolysis current, determine a preset current change rule matching the initial concentration, and start electrolysis with the preset current in the preset current change rule.

[0075] Since the initial concentration of the volumetric electrolyte in the disinfectant solution maker is different when the electrolysis is started, the electrolysis current required for complete electrolysis is also different. Moreover, during the electrolysis process of the electrolyte, the concentration of the electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com