Spraying method of wafer-level sensitive material and semiconductor sensor

A sensitive material, wafer-level technology, applied in the field of sensors, which can solve the problems of poor performance consistency, high cost, and inability to solve high-volume manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

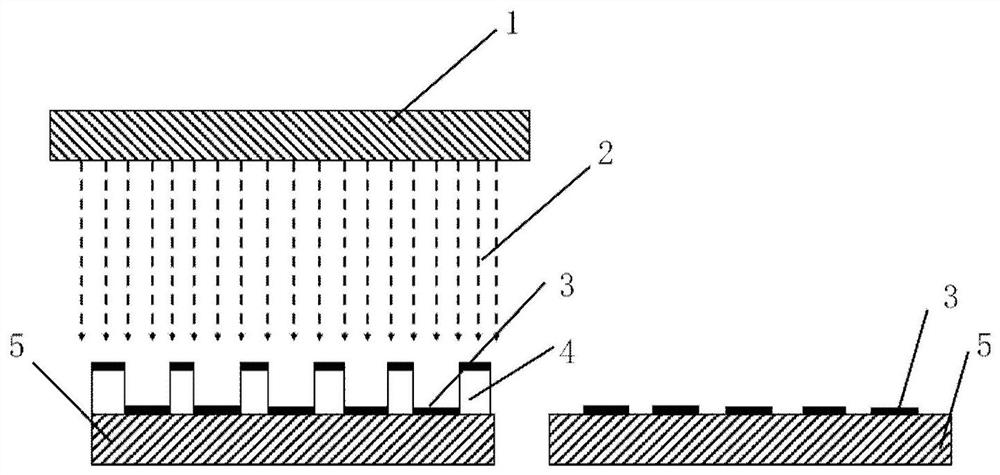

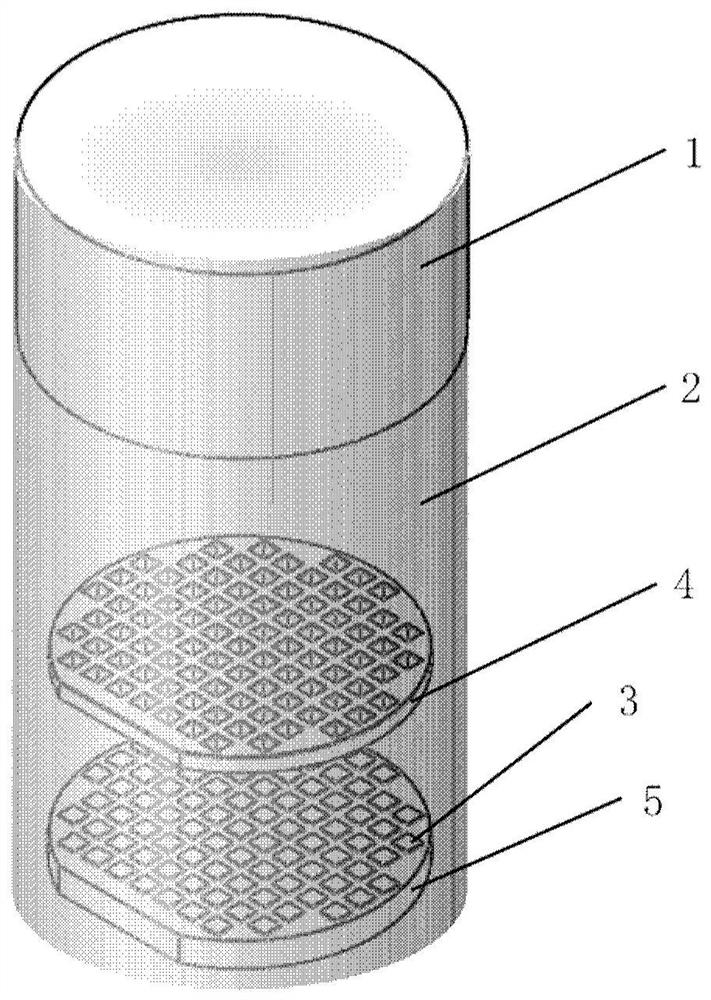

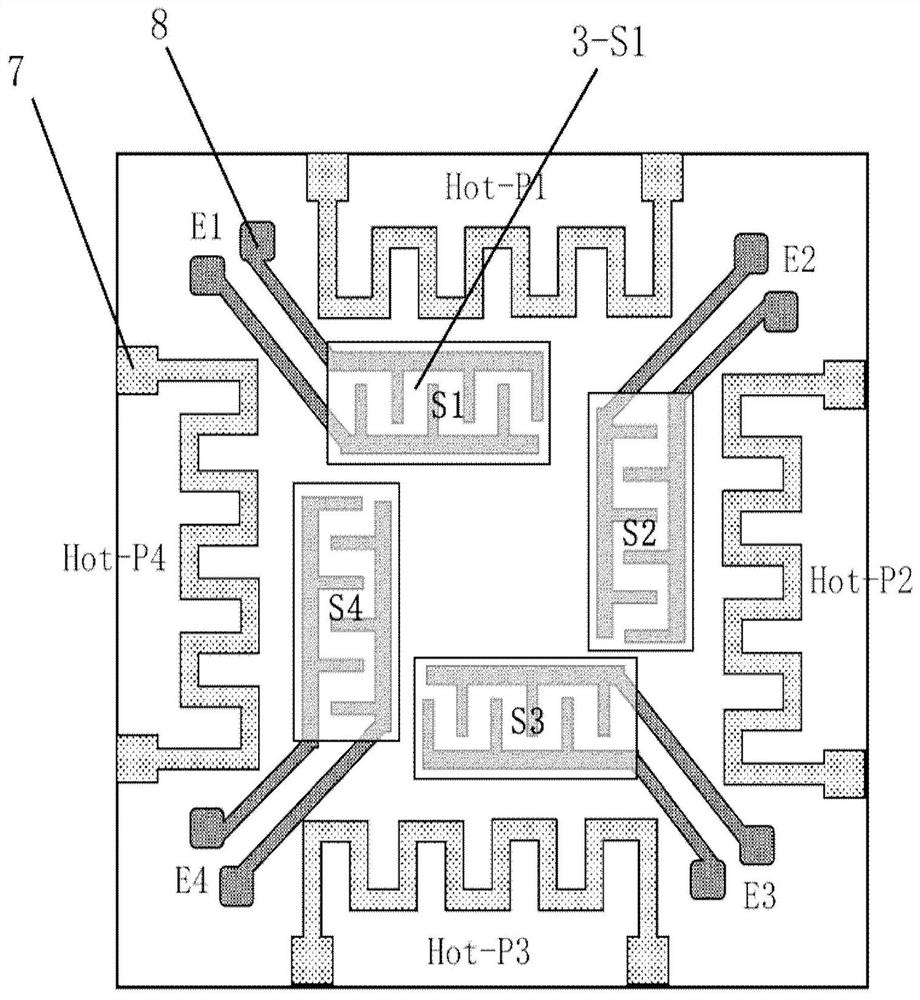

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0021] Aiming at the technical problem of poor consistency in modification and fixation of sensitive materials, a wafer-level sensitive material spraying method was invented, which can precisely control the thickness of the sensitive film while realizing wafer-level modification and fixation of sensitive materials, and achieve perfect compatibility with subsequent processes .

[0022] The invention discloses a method for spraying wafer-level sensitive materials, comprising:

[0023] Align the openings on the prepared mask with the sensitive areas of the substrate;

[0024] Inject the precursor solution of the sensitive material to be coated onto the nozzle;

[0025] Set the nozzle operating parameters;

[0026] Aim the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com