Method for brushing off attachments at flask bottom and flask openings of three-neck flask

A technology for three-neck flasks and attachments, which is applied in cleaning methods and appliances, chemical instruments and methods, and cleaning hollow objects, etc., and can solve problems such as poor cleaning effect, limited bottle mouth radial size and neck length, and inability to clean the bottom of the bottle, etc. , to achieve the effect of expanding volume and area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The method for brushing the bottom of the three-necked flask and the attachments on the bottle mouth of the present invention comprises the following steps:

[0043] S1, the air bag 3 is not inflated, it is in a folded state, and then it is inserted into the bottle body of the three-necked bottle through the middle bottleneck of the three-necked bottle 16;

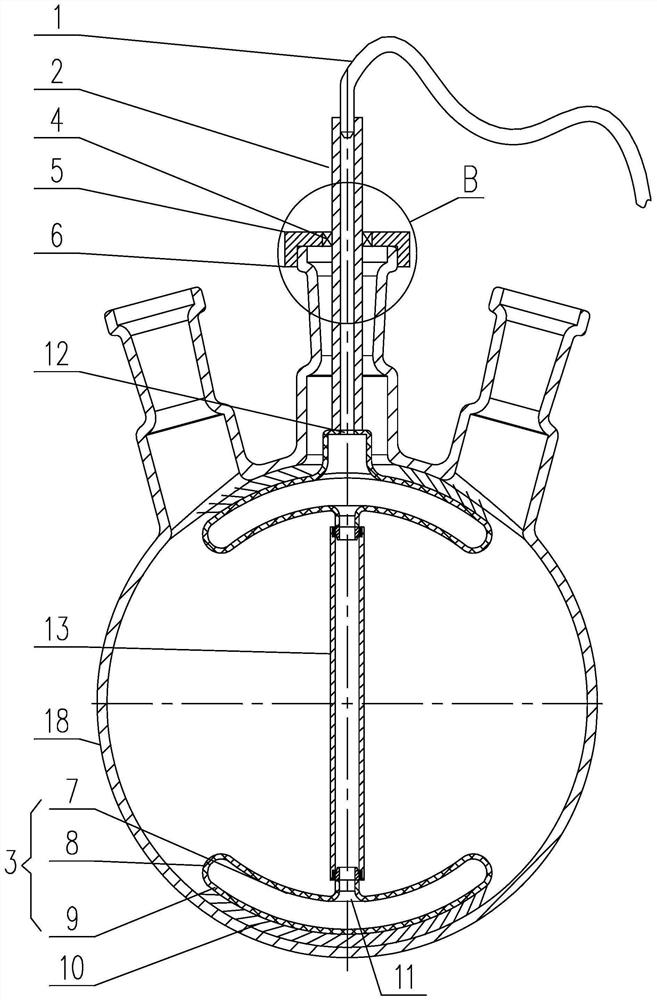

[0044] S2. Insert the bottom end of the straight pipe 2 into the three-necked bottle 16 through the middle mouth of the three-necked bottle 16 until the bottom of the positioning ring 18 contacts the top end face of the middle neck, and the inner wall of the stop ring 19 and the outer wall of the middle neck The upper side fits, such as Figure 4 shown;

[0045] S3, then start the system for supplying pressure gas, so as to inflate the inside of the airbag 3 through the flexible pipe 1 and the straight pipe 2; with the inflation, the airbag 3 is stretched out, the inferior spherical shell in the airbag 3 coincides wi...

Embodiment 2

[0056] This embodiment is on the basis of embodiment 1 to further illustrate the cleaning of the present invention.

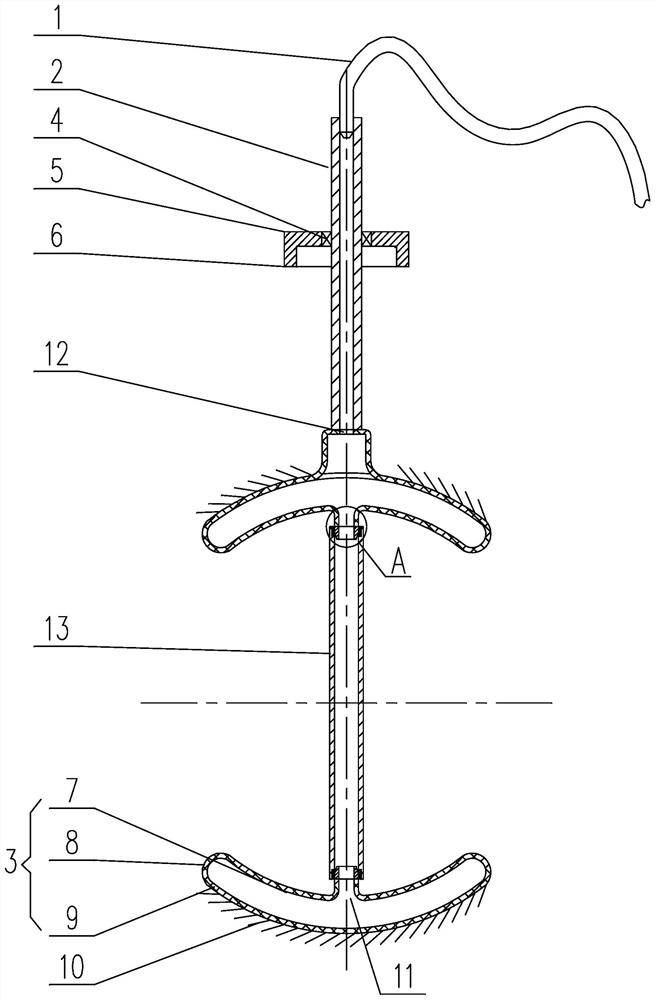

[0057] Such as figure 1 As shown, there are two airbags 3, namely an upper airbag and a lower airbag, and they are symmetrically distributed up and down, and their centers of spheres coincide with each other, and the convex surface of the inferior spherical shell A9 of the upper airbag is fixed on the bottom of the straight pipe 2 , which communicates with the inner hole of the straight pipe 2 through the upper through hole 12 arranged on the inferior spherical shell A9;

[0058] A connecting pipe 13 coaxial with the straight pipe 2 is arranged between the upper airbag and the lower airbag. The upper and lower ends of the connecting pipe 13 are respectively connected to the concave surface of a bad spherical shell B7. The lower end of the connecting pipe 13 is set by The bottom through hole 11 on the inferior spherical shell B7 of the lower air bag communicate...

Embodiment 3

[0062] This embodiment is based on Embodiment 2 to further illustrate the present invention.

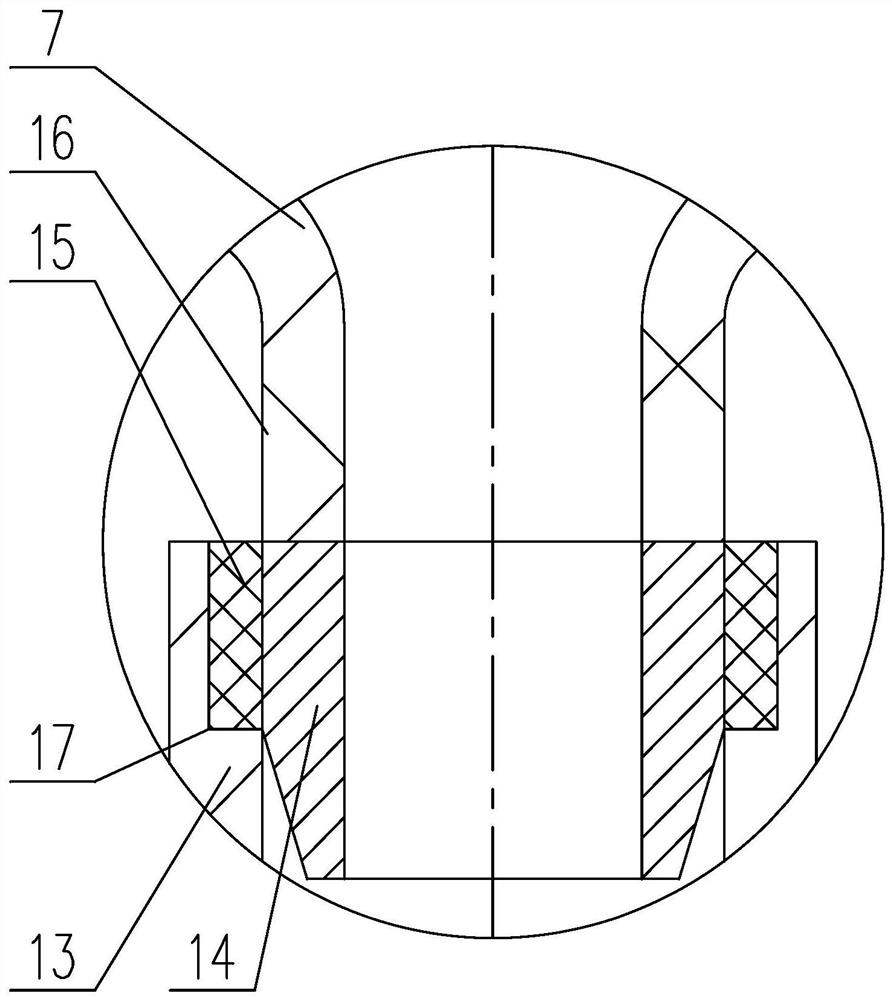

[0063] Such as figure 1 and figure 2 As shown, in the present invention, the air bag 3 is connected to the end of the connecting pipe 13 through a connecting assembly, the connecting assembly includes a hard pipe 14 and a sealing ring 15, and an annular groove 17 is provided at the end of the inner wall of the straight pipe 2 , the outer ring of the sealing ring 15 is installed in the annular groove 17, and the inferior spherical shell B7 protrudes toward the center of the ball along the circumference of the bottom through hole 11 to form a connecting neck 16, and the connecting neck 16 is One end close to the center of the ball is connected to one end of a hard tube 14 , and the other end of the hard tube 14 is inserted into the inner hole of the sealing ring 15 and is interference-fitted with the sealing ring 15 .

[0064] Preferably, the outer peripheral surface of the hard pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com