Numerical control linear cutting machine tool capable of prolonging service life of molybdenum wire

A wire cutting machine tool and molybdenum wire technology, which is applied in electric processing equipment, electrode manufacturing, metal processing equipment, etc., can solve the problems of long distance between the cutting part and the wire drum, shortening the service life of molybdenum wire, fast wear of molybdenum wire, etc., to achieve The effect of shortening the wire threading operation time, reducing the risk of wire breakage, and simplifying the operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

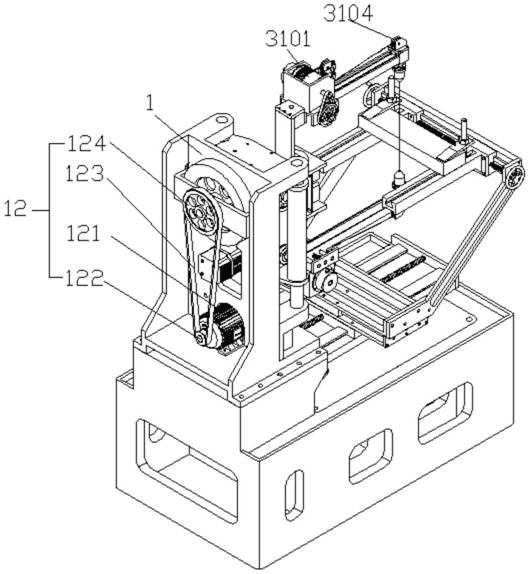

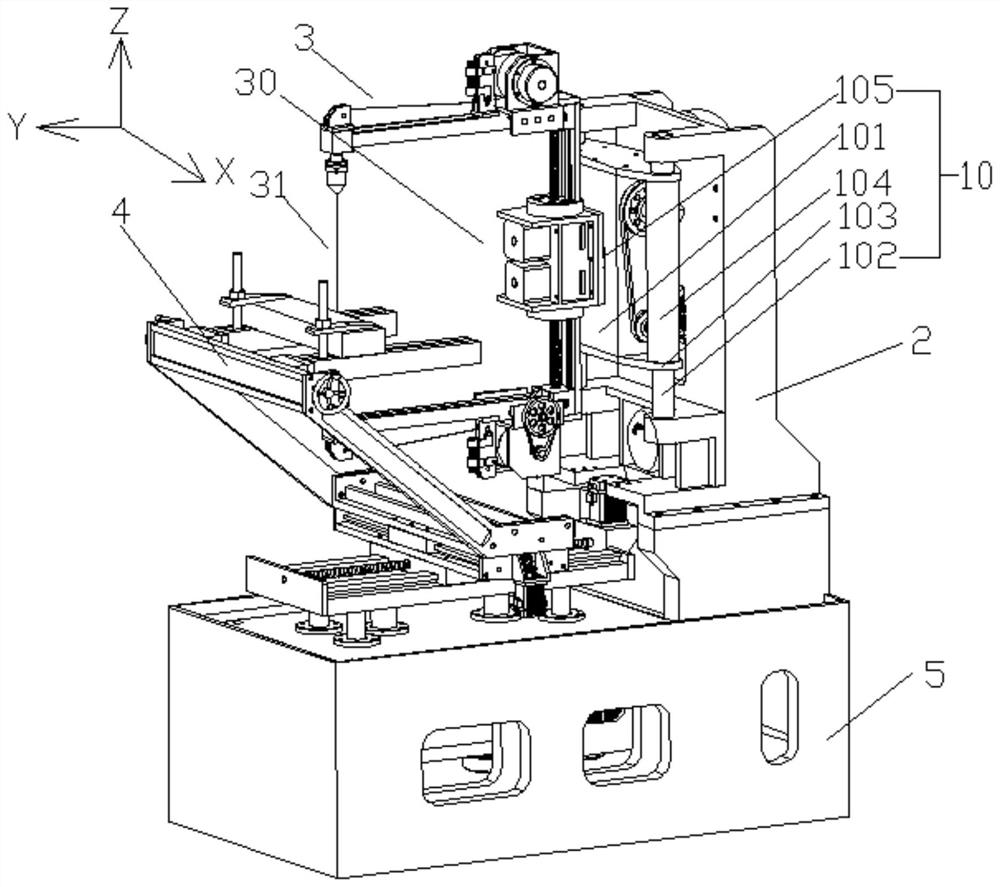

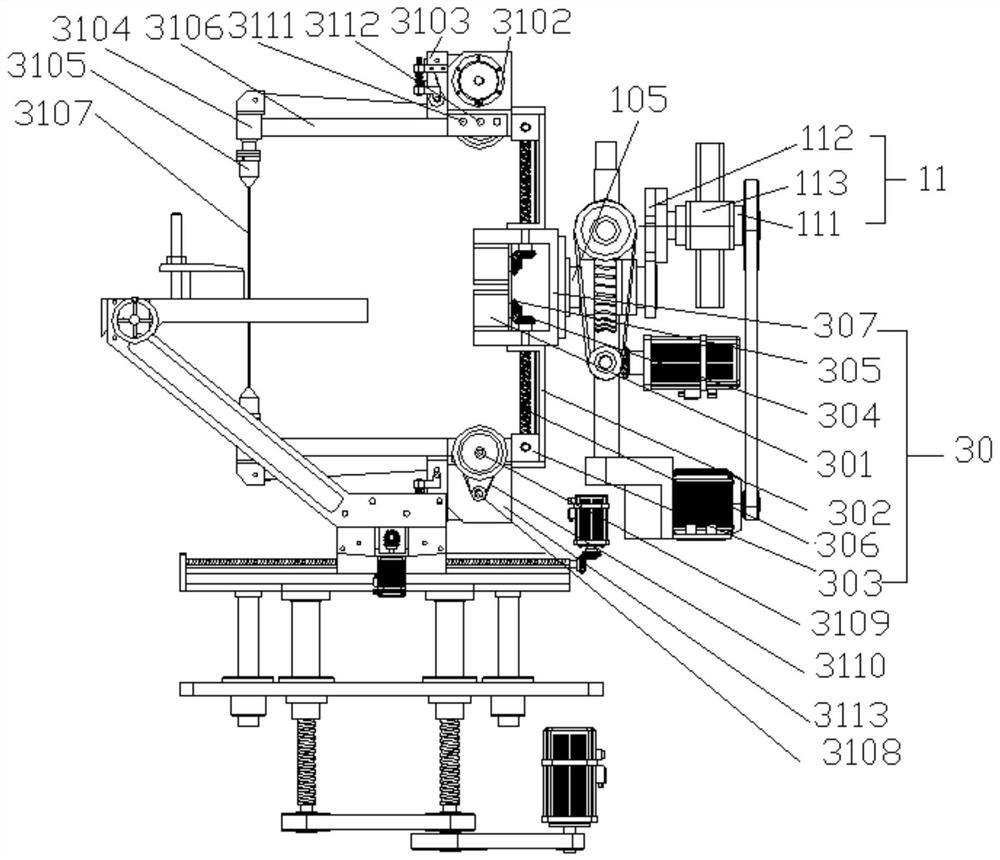

[0020] from figure 1 , figure 2 , image 3 It can be seen that the present invention is a CNC wire cutting machine tool for prolonging the service life of molybdenum wire, which includes a base 5, a main frame 2, a worktable 4, and a wire conveying mechanism 3. The main frame 2 is fixed on the support block on the right side of the base 5, and the worktable 4 is connected with the base 5, and it also includes an oscillating auxiliary cutting mechanism 1. The oscillating auxiliary cutting mechanism 1 includes a power output part 12, a crank connecting rod part 11, and a box body part 10; the power output part 12 is connected with the main frame 2 and the crank connecting rod part. 11 is connected, the crank connecting rod part 11 is connected with the box body part 10 , and the box body part 10 is fixed on the main frame 2 and connected with the wire conveying mechanism 3 .

[0021] The numerical control wire cutting machine tool of the present invention: the power output pa...

Embodiment 2

[0023] The numerical control wire cutting machine tool of the present invention: the power output part 12 includes an asynchronous motor 121, a small pulley I122, a belt I123, and a large pulley I124; the asynchronous motor 121 is fixed on the bottom plate of the main frame 2, and the small pulley I122 is fixed on the asynchronous motor 121 On the output shaft, the large pulley I124 is connected with the crank connecting rod part 11, and the belt I123 is connected with the small pulley I122 and the large pulley I124; the box body part 10 includes a box body 101, two front and rear guide posts 102, two upper and lower stoppers Plate 103, oscillating shaft 105; two guide posts 102 are arranged in parallel at the front and rear, the upper and lower ends of which are respectively connected with the upper and lower connecting blocks of the main frame 8, and the two baffles 103 are sleeved on the front and rear guide posts 102, and the two The two ends of the oscillation shaft 105 ar...

Embodiment 3

[0026] The CNC wire cutting machine tool of the present invention: the crank connecting rod component 11 includes a crankshaft 111 and a connecting rod 112. One end of the crankshaft 111 is connected to the large pulley 124 after passing through the support plate on the right side of the main frame 2, and the other end is connected to a hole on the connecting rod 112. , the other hole on the connecting rod 112 is connected with the oscillation shaft 105 .

[0027] The function of the crank connecting rod component is: the large pulley 124 drives the crankshaft 111 to rotate, and the crankshaft 111 drives the connecting rod 112 to swing, so that the oscillation shaft 105 moves up and down, and the wire transport mechanism connected to the oscillation shaft 105 moves up and down to realize oscillation, and the wire frame reciprocates quickly. The movement simulates the high-speed rotation of the wire drum, so that even if the molybdenum wire is short, it can cut the workpiece wit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap