Circuit device and method for improving consistency of thermal printing concentration

A technology of thermal printing and thermal print head, which is applied in printing and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

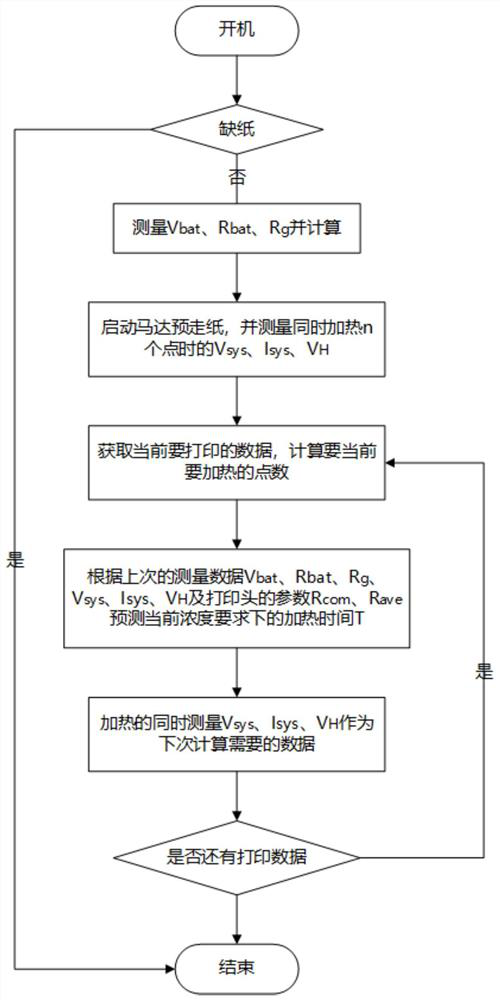

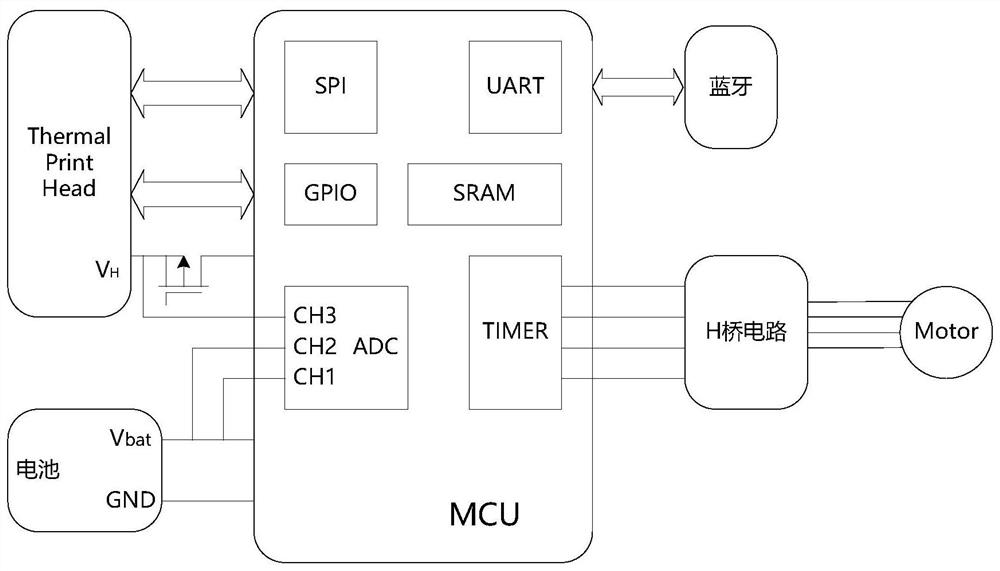

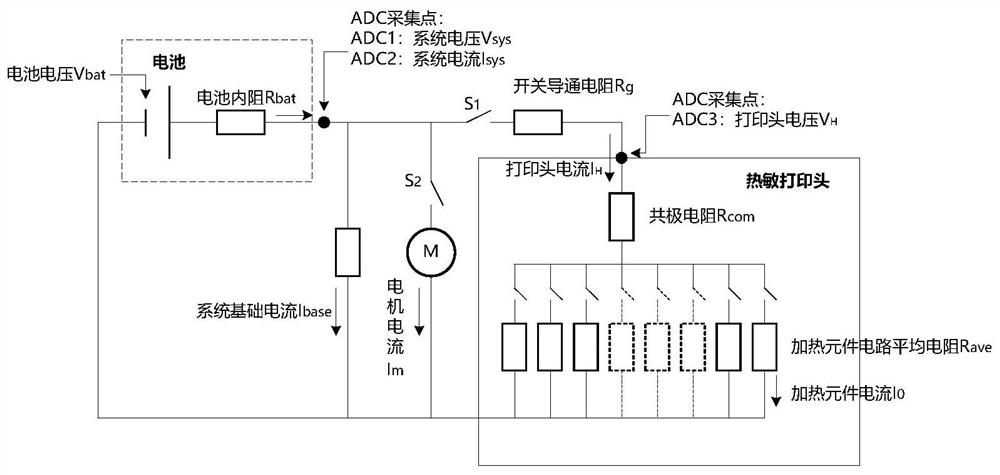

[0076] First aspect, such as Figure 1-3 As shown, the present invention provides a technical solution: the present invention provides a circuit method for improving the density consistency of thermal printing, which includes the following steps: after the thermal printer is turned on, first measure and calculate the battery voltage V bat , battery internal resistance R bat , the on-resistance R of the thermal print head power switch g :

[0077] a. Check whether there is paper, otherwise exit;

[0078] b. The switch S1 is off, the thermal print head is not powered; the switch S2 is off, the motor is off;

[0079] c. ADC1 and ADC2 work, respectively measure V multiple times sys , I sys , remove unreasonable sampling values, and calculate V sys and I sys The average value is used as the measured rms value of V sys [0] and I sys [0];

[0080] d. Divide the N heating points in a row on the thermal head into m1 groups, and each group has n1 heating points. The selection ...

Embodiment 2

[0092] Such as Figure 1-3 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: start the motor to pre-feed the paper, and start the measurement at the same time to prepare for the official printing, including the following steps:

[0093] a) Start the motor and gradually accelerate to the predetermined speed;

[0094] a, b) Divide the N heating points in a row on the thermal head into m2 groups, each group has n2 heating points, where n2 is selected reasonably, which is the same as the number of heating points selected during normal printing, and the points in the m2 group are heated sequentially at the same time, The heating time T2 is set so as not to cause the thermal paper to develop color. During each heating period, a reasonable interval is selected to perform multiple ADC1, ADC2, and ADC3 measurements, and unreasonable sampling values are eliminated, and V is calculated. sys , I sys and V H The average value is used as the m...

Embodiment 3

[0098] Such as Figure 1-3 As shown, on the basis of embodiment 1 and embodiment 2, the present invention provides a kind of technical scheme: preparation is completed, start printing, comprise the following steps:

[0099] a) get a little line from the print buffer data, carry out reasonable segmentation, obtain the point number that needs to print at present and be n3, set I mbase is the total current consumed by the system and the motor, and the formula ⑦ is obtained:

[0100] I mbase [2] = I base [2]+I m [2] = I sys [2]-I H [2] ⑦

[0101] The equivalent resistance of the system and the two circuits of the motor is Rmbase; it can be obtained from any of the following formulas ⑧ and ⑨:

[0102]

[0103] or:

[0104] b) Calculate the equivalent resistance R of the print head path when the current number of printing points is n3 H [3]: by the formula

[0105] ⑩or Calculate the total resistance R[3] of the system:

[0106]

[0107]

[0108] c) When the num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com